Large-stroke translation mechanism for long-edge side barrier strip of foaming mold of side-by-side combination refrigerator door body

A refrigerator door body and foaming mold technology, which can be applied to household appliances, other household appliances, applications, etc., can solve the problems of heavy weight of aluminum alloy material process lining blocks, inconvenient picking and placing, and difficult fixing of tapes, etc., to achieve process saving cost, reduce labor, and improve product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

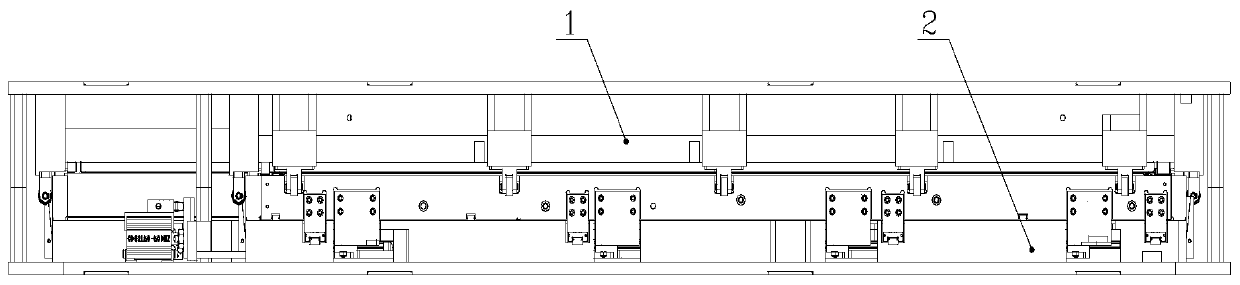

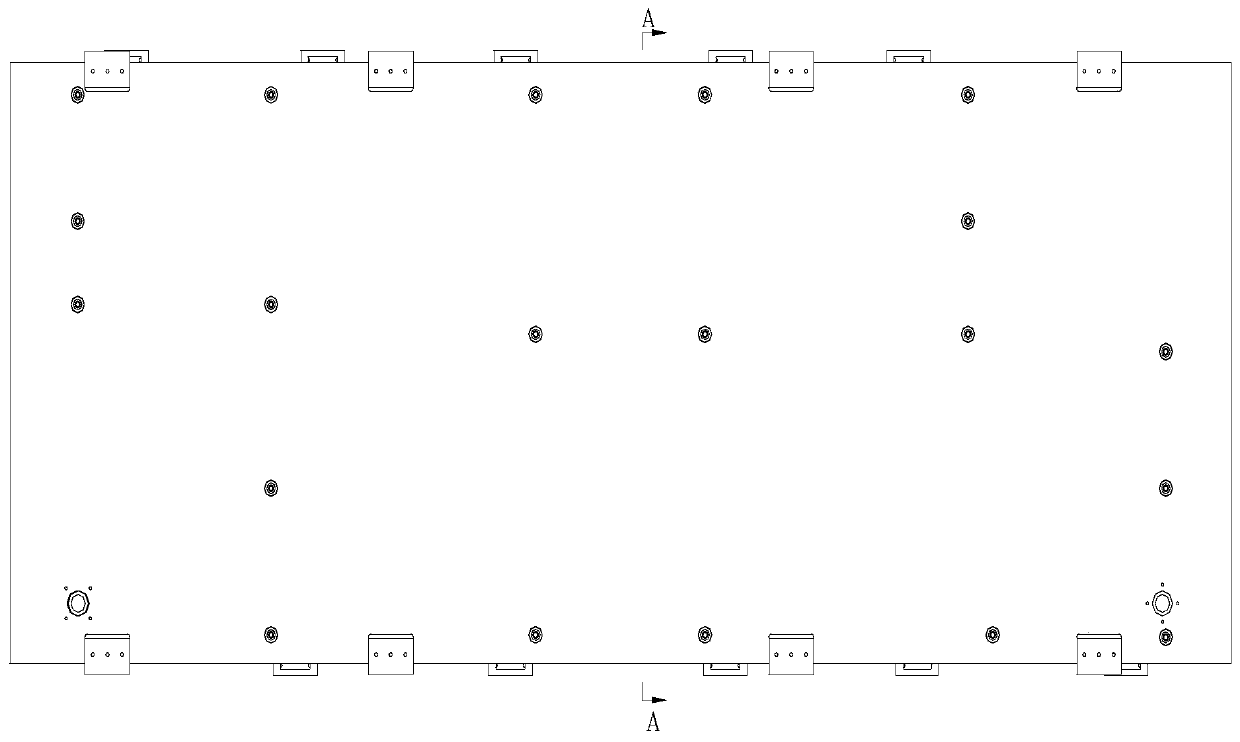

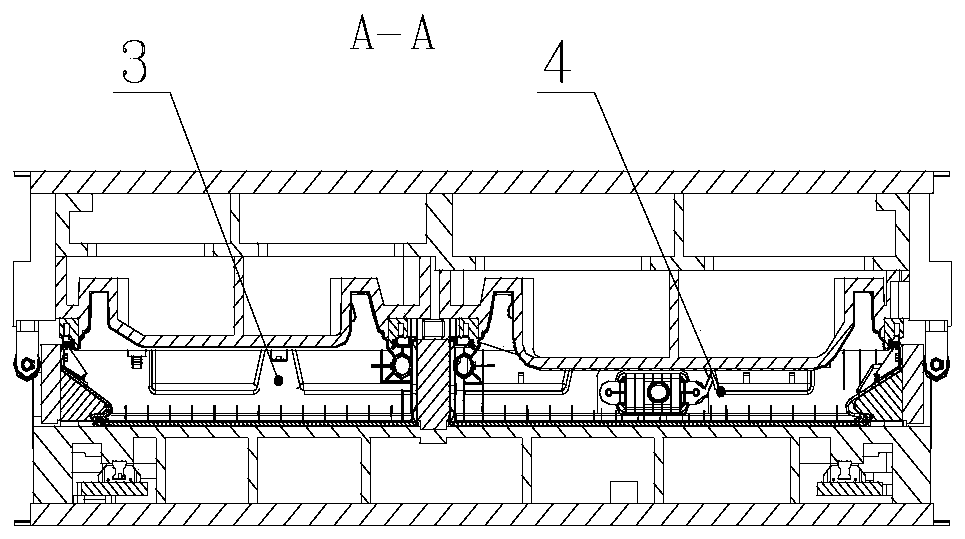

[0026] In this embodiment, the freezer door body 3 and the refrigerated door body 4 of the open-door refrigerator respectively apply a method of the present invention for foaming and processing the hidden handle of the long-side side bar large-stroke translation mechanism of the foam mold for the door body of the open-door refrigerator. , the mechanisms adopted by the two operations are exactly the same, namely:

[0027] The foaming mold for the side-by-side refrigerator door body is mainly composed of an upper mold 1 and a lower mold 2, and the long-side side bar large-stroke translation mechanism is a translation bar assembly 28 arranged on the lower mold 2 , the translation bar assembly 28 includes an air block 41, a cylinder 46, a cylinder connection block 45, a connecting plate A43, a connecting plate B44, a movement plate, a translation bar, a handle pad, a guide block 42, and a cam bearing along with Actuator 37, translation bar connecting plate 36, slider A connecting ...

Embodiment 2

[0034] Figure 1 to Figure 12 Then the structure of another preferred embodiment of the present invention is shown. The structure different from embodiment 1 is mainly that the upper mold core of the upper mold 1 includes a refrigerating upper mold core 13 and a freezing upper mold core 11. The bar of lower mold 2 comprises freezing left bar 25, refrigerated left bar 26, freezing right bar 29, refrigerated right bar 30 and refrigerating and freezing intermediate fixed bar 27, forming respectively with freezing upper mold core 11, refrigerating upper For the freezing cavity and the refrigerating cavity corresponding to the mold core 13, the refrigerating and freezing intermediate fixed bar 27 is fixed on the lower pad 31, and the refrigerating and freezing intermediate fixed bar 27 is fixed with a limit block 16; the translation bar assembly 28 It is divided into a freezing translation bar assembly and a refrigerated translation bar assembly, both of which have the same structu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com