A twisted cage discharge system and discharge method for swill separation

A discharge system and twisted cage technology, applied in the field of discharge system, can solve the problems of untimely discharge, inability to adjust and control the moisture content of the extruded material, etc., and achieve the effect of reducing the discharge amount and improving the speed and effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

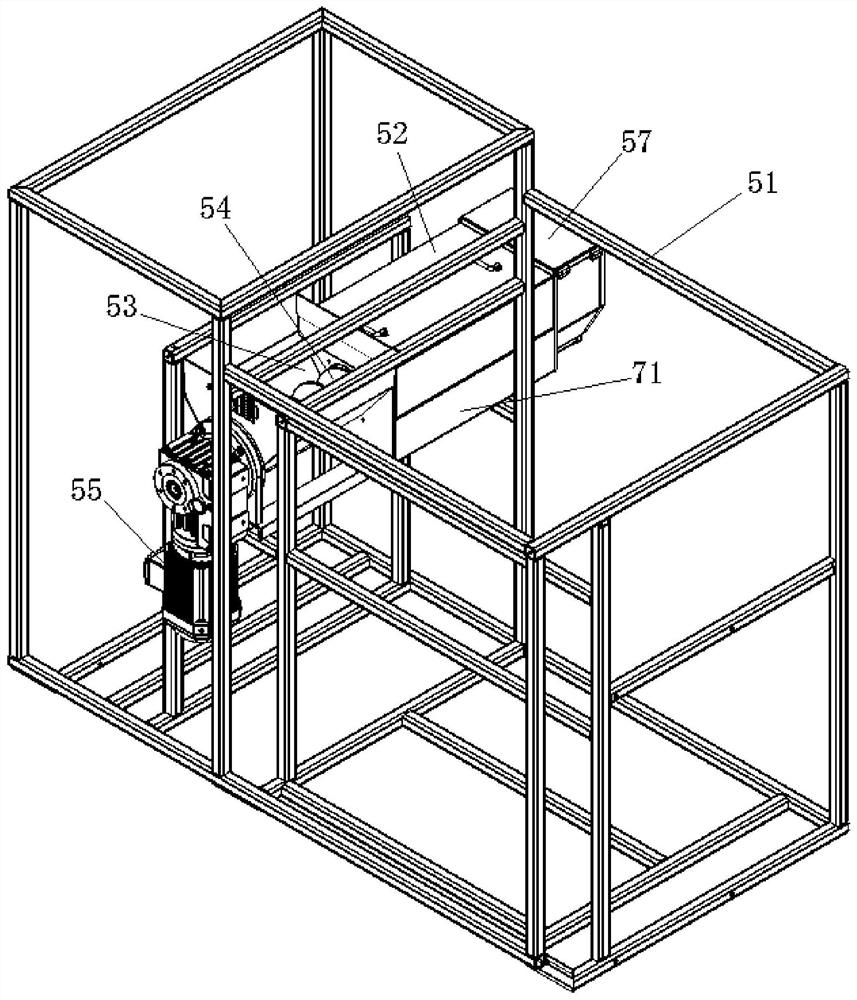

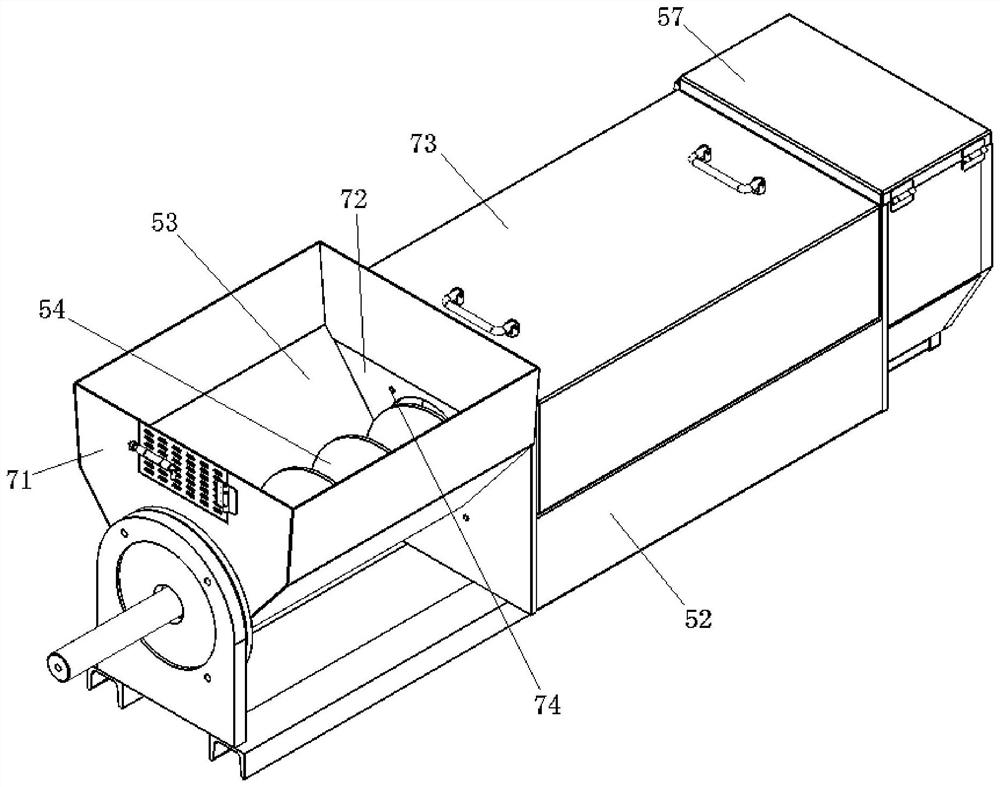

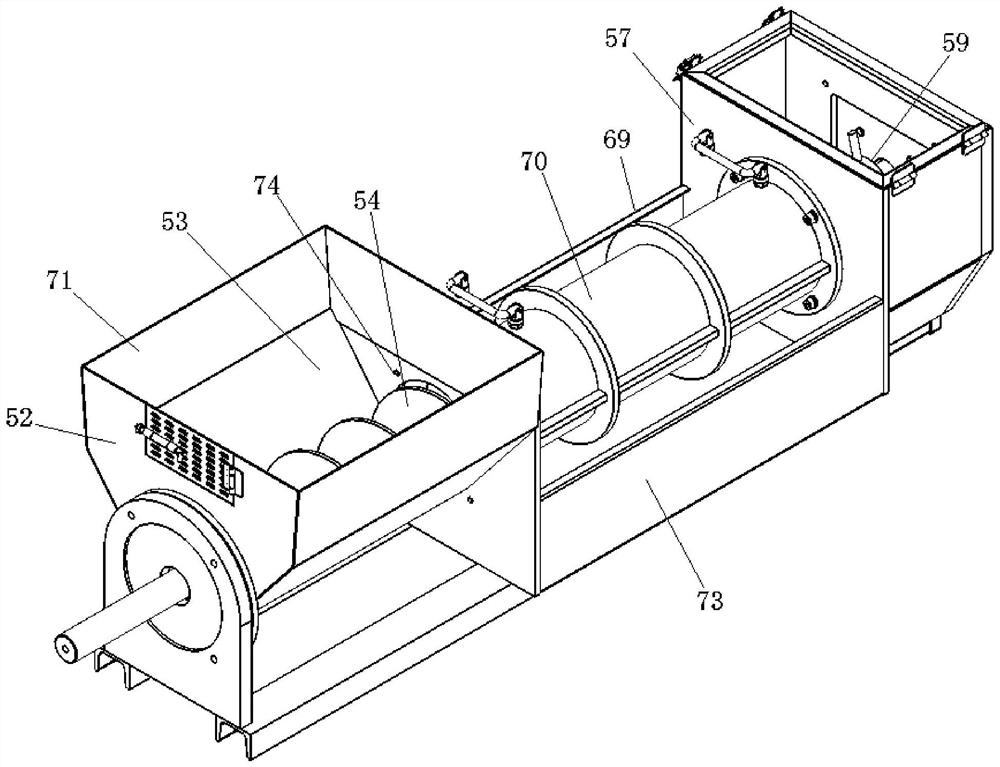

[0068] see Figure 1-9 , this embodiment provides a twisted cage discharge system for swill separation, which is used to squeeze, dehydrate and discharge kitchen swill. The twisted cage discharge system can be used as a part of the kitchen swill treatment equipment, or it can be set up as an independent system. Wherein, the twisted cage discharge system includes an extrusion frame 51, an extrusion shell 52, a screw rod 54, an extrusion motor 55 and a locking mechanism, and may also include an outlet pipe.

[0069] The extruding frame 51 is composed of a plurality of square tubes spliced together, and the splicing method can be welding, clamping, screwing, etc., and of course it can also be integrally formed. The bottom end of the extruding frame 51 can be provided with structures such as pulleys, so that the extruding frame 51 can move on the ground. At the same time, the bottom of the extruding frame 51 can also be provided with a limit structure, which can limit the move...

Embodiment 2

[0081] see Figure 10 , this embodiment provides a twisted cage discharge system for swill separation, which adds a moisture sensor 63 and an extrusion controller on the basis of Embodiment 1. Wherein, the moisture sensor 63 is used to detect the moisture content of the kitchen swill entering the extrusion chamber 52, and it can be installed in the extrusion chamber 52 where the kitchen swill first enters.

[0082] The squeeze controller is used to judge whether the water content is less than a preset water content ratio one and greater than a preset water content ratio two. When the water content is less than the preset water content ratio 1 and greater than the preset water content ratio 2, the extrusion controller drives the extrusion motor 55 to increase the rotation speed according to the difference between the water content ratio and the preset water content ratio 2. Wherein, the increase value of the rotational speed is positively correlated with the difference value. ...

Embodiment 3

[0085] see Figure 11 , this embodiment provides a twisted cage discharge system for swill separation, which adds a funnel 64 and a stirring assembly on the basis of Embodiment 1. The funnel 64 is installed on the extruding shell 52 , and the bottom end communicates with the extruding cavity 52 near the end of the extruding shell 52 . The stirring assembly is installed in the funnel 64 and is used to stir the kitchen swill in the funnel 64 . Wherein, the stirring assembly includes a stirring motor 65 , a stirring shaft 66 and a plurality of stirring fan blades 67 . The stirring motor 65 is installed on the extruding frame 51 , and the output shaft is connected with the stirring shaft 66 . A plurality of stirring fan blades 67 are arranged around the axial direction of the stirring shaft 66 and fixed on the stirring shaft 66 .

[0086] The funnel 64 of the twisted cage discharge system used for the separation of swill can be used for receiving materials, and the stirring ass...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com