Swill three-phase separation device with crushing and extrusion function and three-phase separation method thereof

A three-phase separation and swill technology, which is applied in the field of swill three-phase separation, swill three-phase separation device, and swill three-phase separation device with crushing and extrusion function, can solve the problem that the dry humidity of the extruded material cannot be adjusted and controlled, and the swill large particles blockage etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

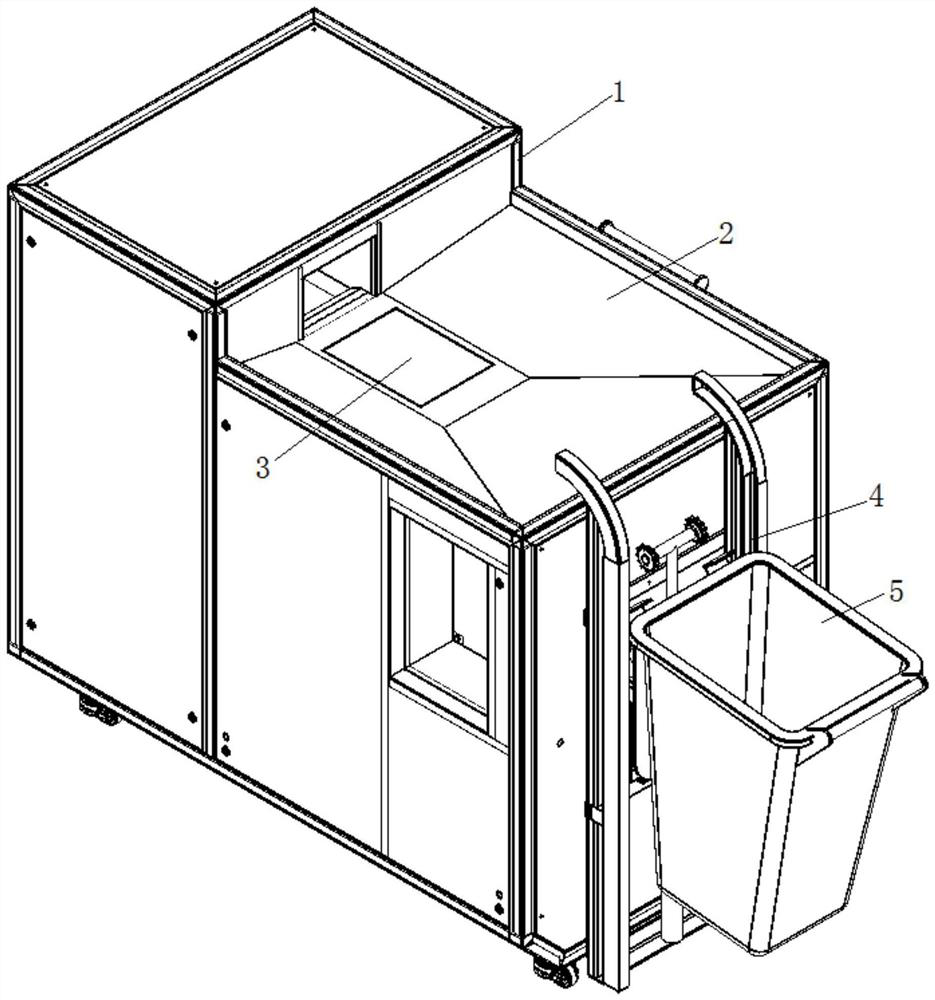

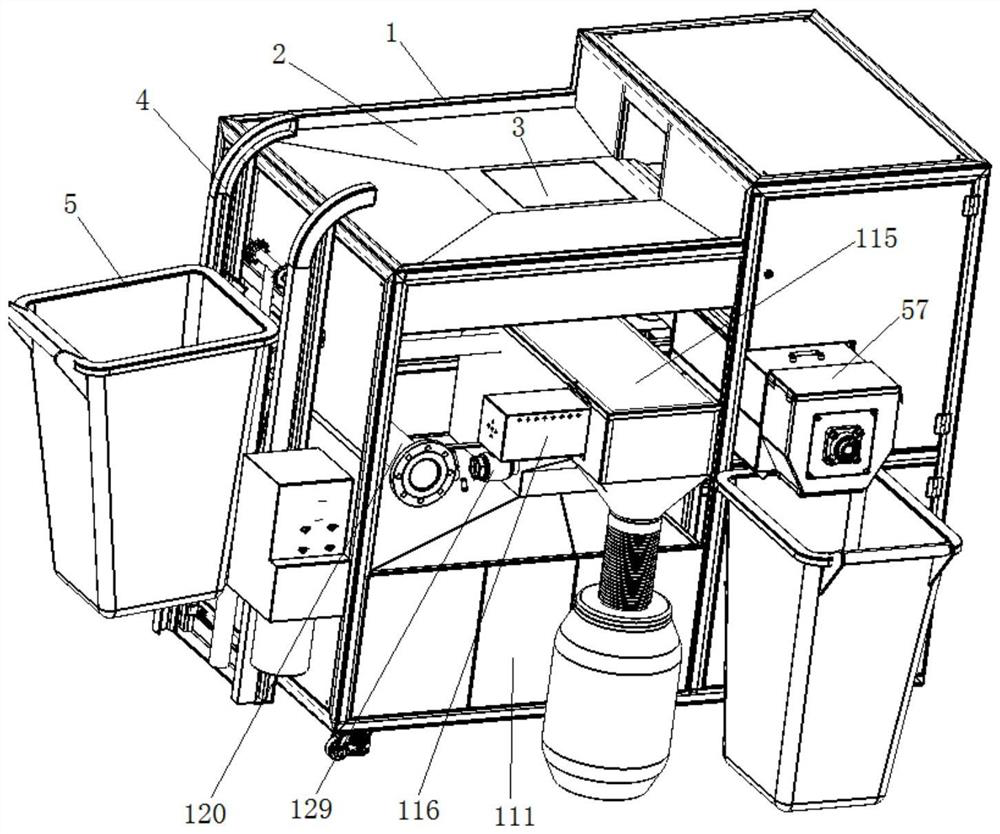

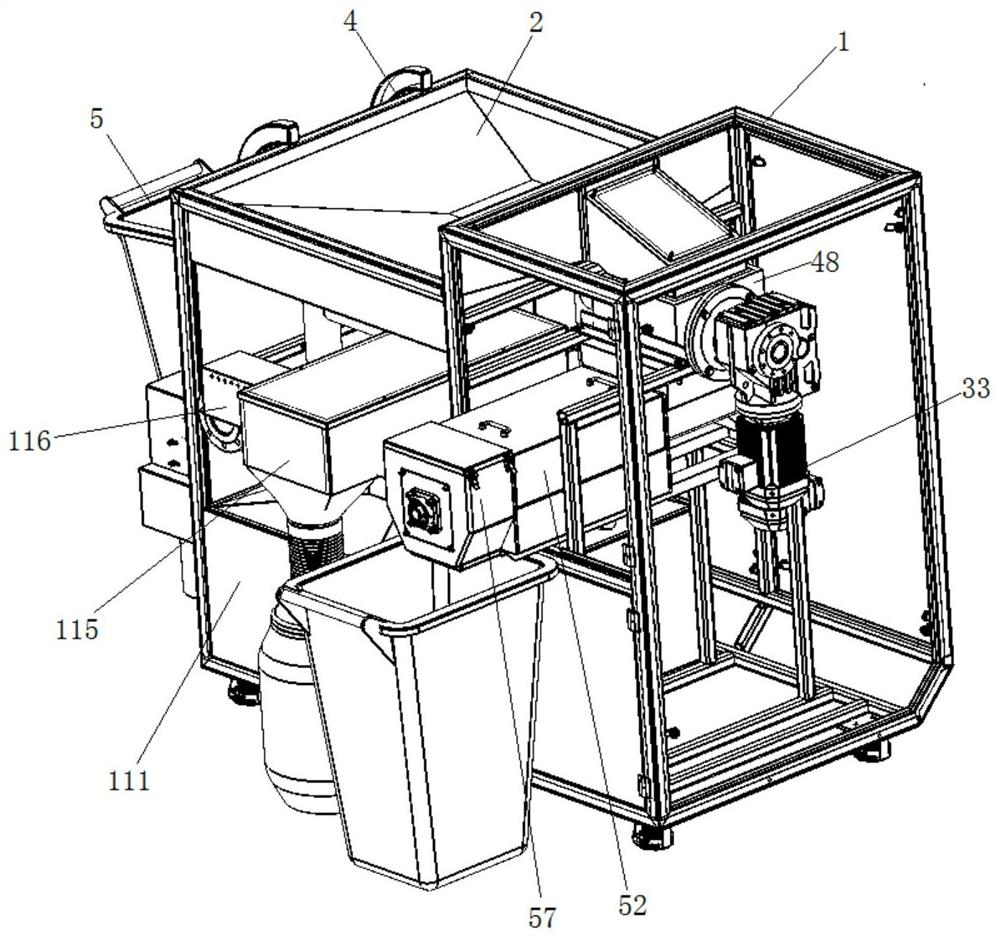

[0079] see figure 1 , figure 2 as well as image 3 , This embodiment provides a three-phase separation device for swill with a crushing and extrusion function, which is used for three-phase separation of kitchen swill, and separates solid garbage, waste water and grease. Wherein, the swill three-phase separation device includes a frame body 1, a sorting system, a crushing system, an extrusion system, an oil-water separation system, and a feeding system.

[0080] The frame body 1 is composed of a plurality of square tubes spliced together, and the splicing methods can be welding, clamping, screwing, etc., and of course can also be integrally formed. The bottom end of the frame body 1 can be provided with structures such as pulleys, so that the frame body 1 can move on the ground. At the same time, the bottom of the frame body 1 can also be provided with a limit structure, which can limit the movement of the frame body 1 on the ground and ensure that the frame body 1 is st...

Embodiment 2

[0110] see Figure 16 , this embodiment provides a three-phase separation device for swill with a crushing and squeezing function, which refines the statistical mechanism on the basis of Embodiment 1 (the flushing mechanism is not shown in the figure).

[0111] The detection component one includes a slide plate one 43 and a load cell one 44 . The first slide plate 43 is installed on the frame body 1 and arranged obliquely, and one end inclined downward faces the preset rolling space. The wet garbage slides from the slide plate one 43 into the preset rolling space. Load cell one 44 is installed between frame body 1 and slide plate one 43, and is used for detecting the weight of the wet garbage that is positioned on slide plate one 43. In this embodiment, it is assumed that the sliding speed of the wet garbage on the sliding plate 43 is a fixed value, which can be measured in advance, and the sliding length of the wet garbage on the sliding plate 43 is also a fixed value, then...

Embodiment 3

[0122] see Figure 17 , this embodiment provides a three-phase separation device for swill with a crushing and extrusion function, and its crushing system adds an electromagnet 25, a slide rail 26, an electric slider 27, and a load cell 28 on the basis of the embodiment 1 And the magnetic material recovery bin 47.

[0123] The electromagnet 25 is installed on the frame body 1, and is located above the preset rolling space, and is used for magnetically absorbing magnetic impurities in the wet garbage. The slide rail 26 is installed on the frame body 1, and one end thereof is located above the preset rolling space. Electric slide block 27 is installed on the slide rail 26, and can slide on slide rail 26. Electromagnet 25 is connected with electric slide block 27 by load cell three 28. The load cell 3 28 is used to detect the total weight of the magnetic impurities adsorbed on the electromagnet 25 . The magnetic material recovery bucket 47 is located below the other end of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com