Heat dissipation device and heat dissipation method of vehicle-mounted liquid cooling system

A heat dissipation device and heat dissipation method technology, applied in the direction of power devices, electric power devices, vehicle components, etc., can solve the problems of high dependence on heat dissipation fans, unfavorable vehicle noise control, and failure to work normally, so as to avoid excessive fan noise, The effect of reducing energy consumption and speed reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] For ease of understanding, the present invention will be further described below in conjunction with the accompanying drawings.

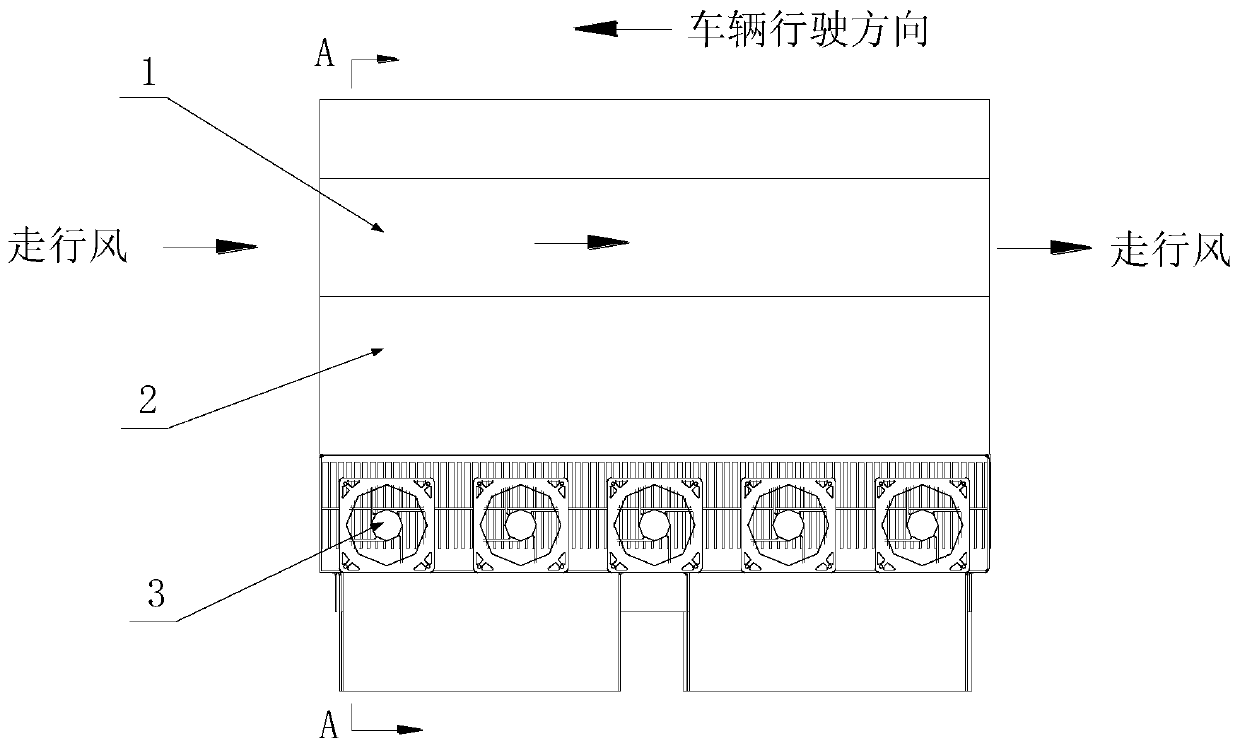

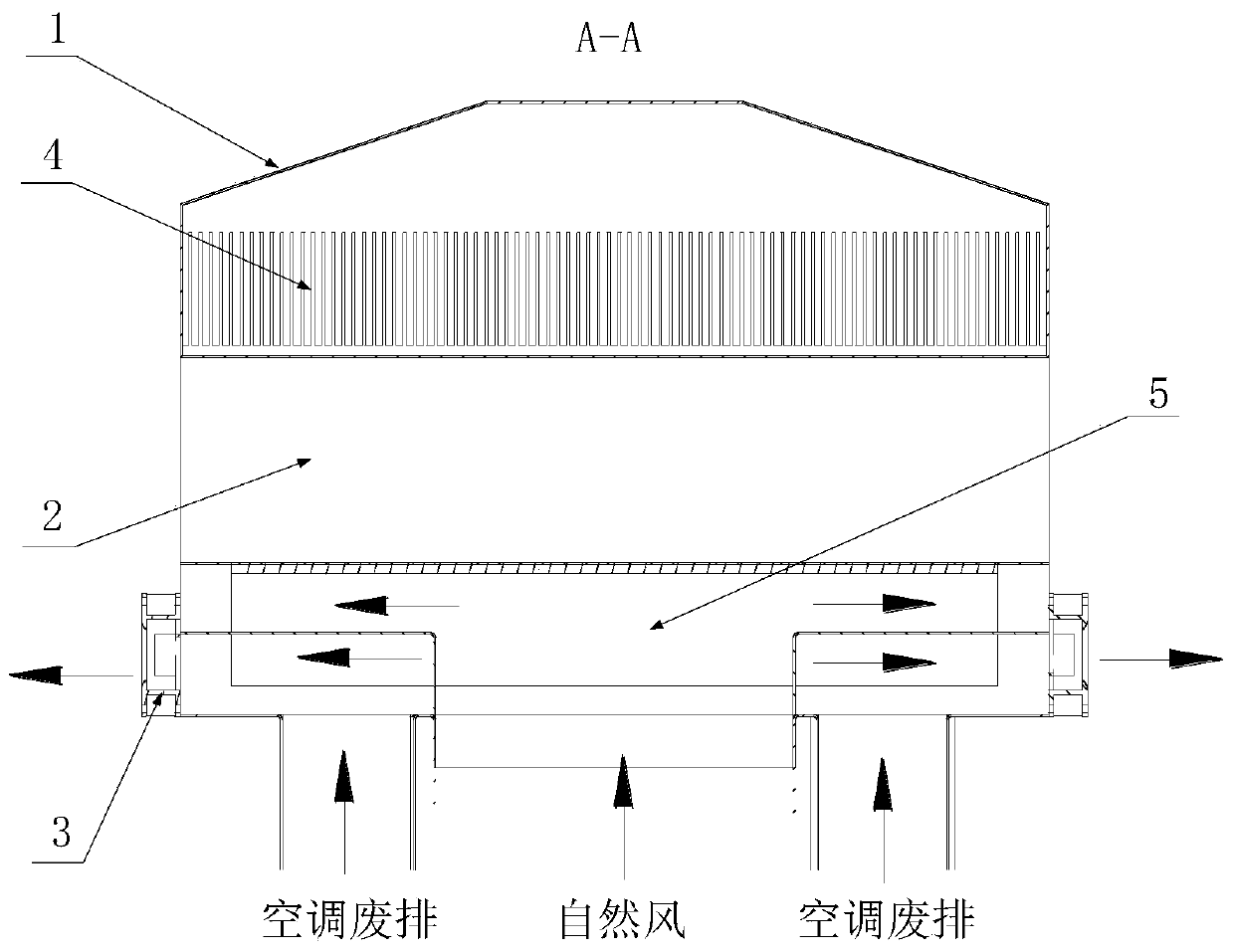

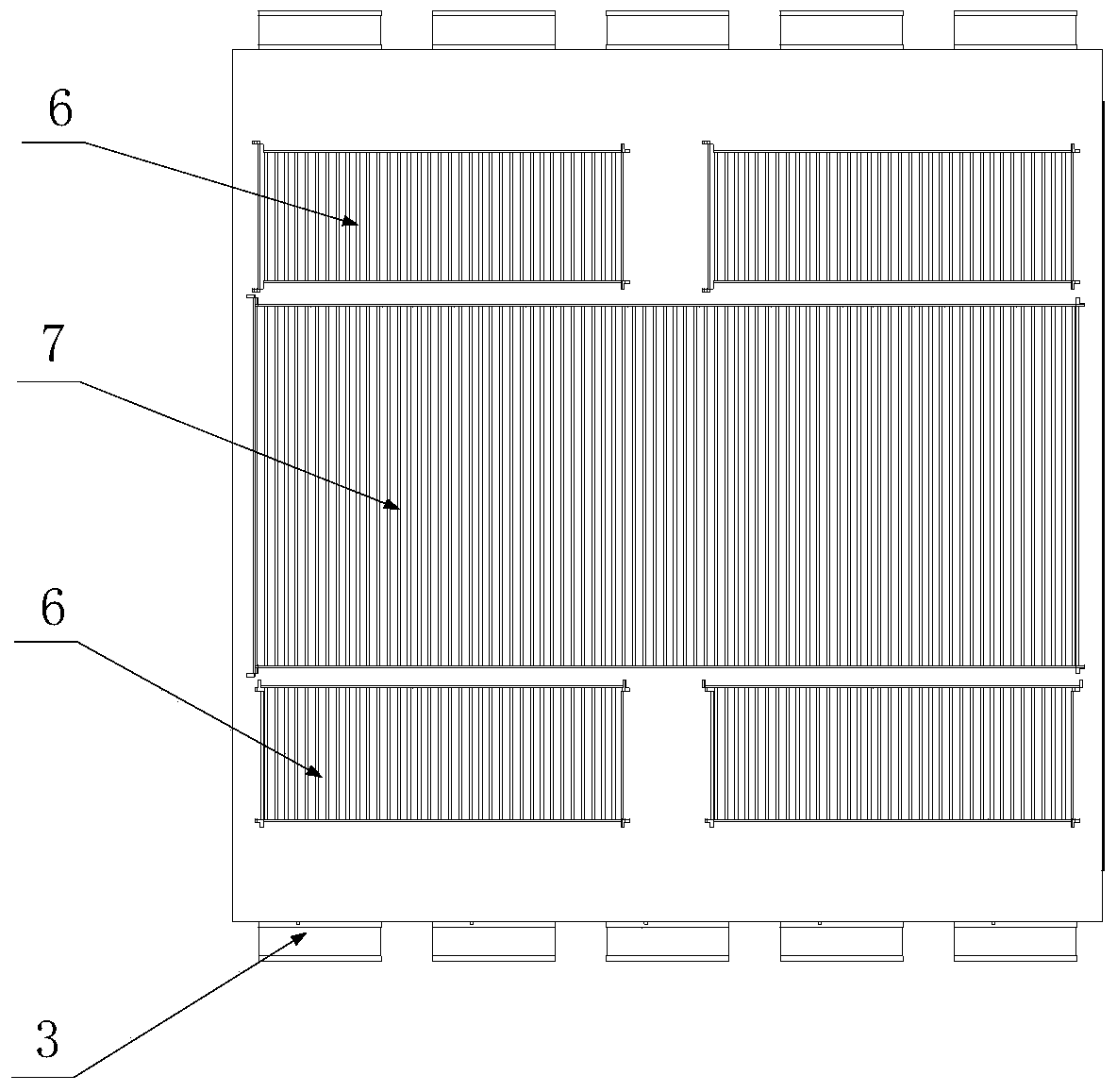

[0034] see Figure 1 ~ Figure 3 , figure 1 It is a schematic front view of a heat dissipation device for a vehicle-mounted liquid cooling system provided by an embodiment of the present invention, figure 2 yes figure 1 Schematic diagram of the section A-A in the middle, image 3 yes figure 1 bottom view.

[0035] The heat dissipation device for the vehicle-mounted liquid cooling system provided by the embodiment of the present invention includes a top cover 1, a liquid tank 2 and an air box, wherein the liquid tank 2 is used to communicate with the circulation pipeline of the cooling liquid, and the cooling in the vehicle-mounted liquid cooling system The liquid flows into the liquid tank 2 after passing through the object to be cooled (such as a battery reactor, etc.), and flows back to the object to be cooled after the temperature of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com