A refueling mechanism for elevator sliding guide shoes

A technology of sliding guide shoe and refueling mechanism, applied in elevators, transportation and packaging, etc., can solve problems such as affecting the normal operation of elevators, and achieve the effects of reducing noise and shaking, simple operation, and reducing waste.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

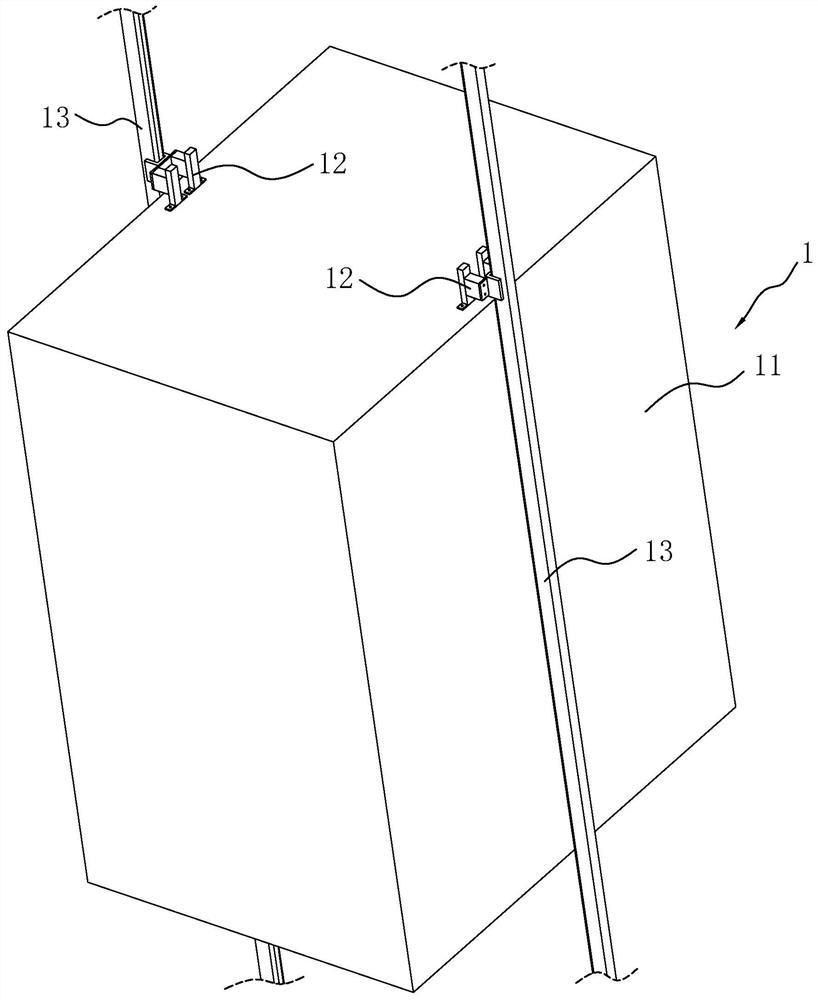

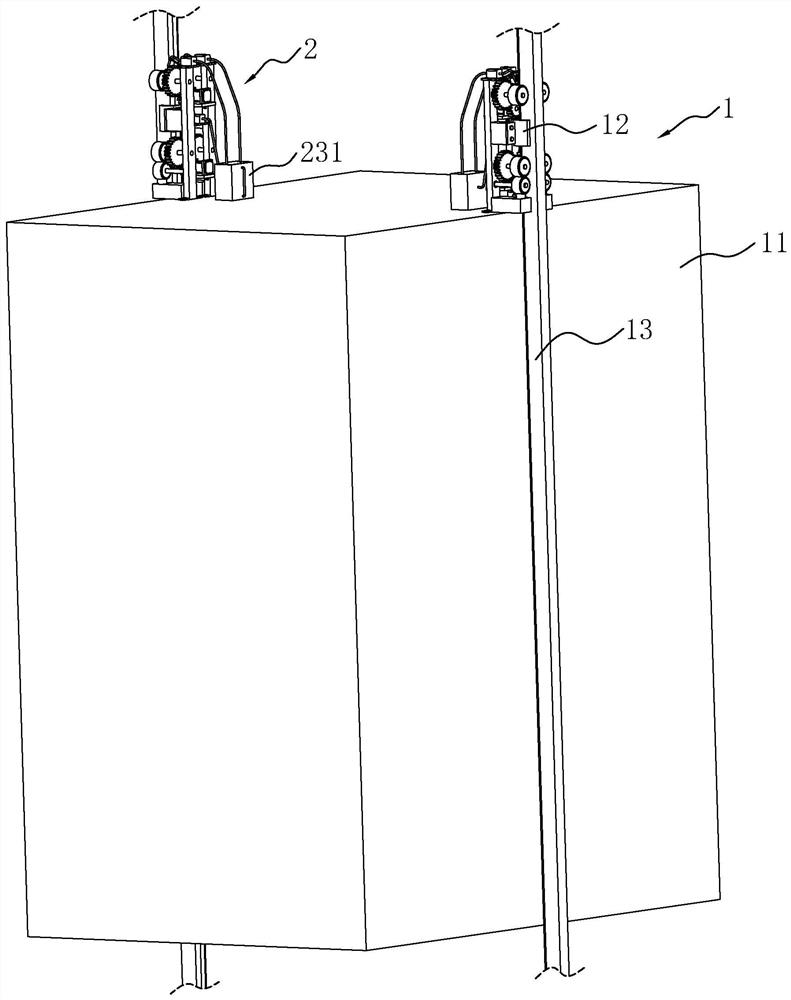

[0037] Embodiment: a kind of refueling mechanism for elevator sliding guide shoe, as figure 2As shown, it is installed on the elevator 1. The elevator 1 includes a car 11, a guide shoe 12 arranged on the outer wall of the car 11, and a guide rail 13 slidingly connected with the guide shoe 12. The guide rail 13 is set as two rollers arranged in parallel. , guide rail 13 is arranged on the both sides of car 11, and is positioned at the middle part of car 11, and the upper and lower ends of guide rail 13 are fixed in the building.

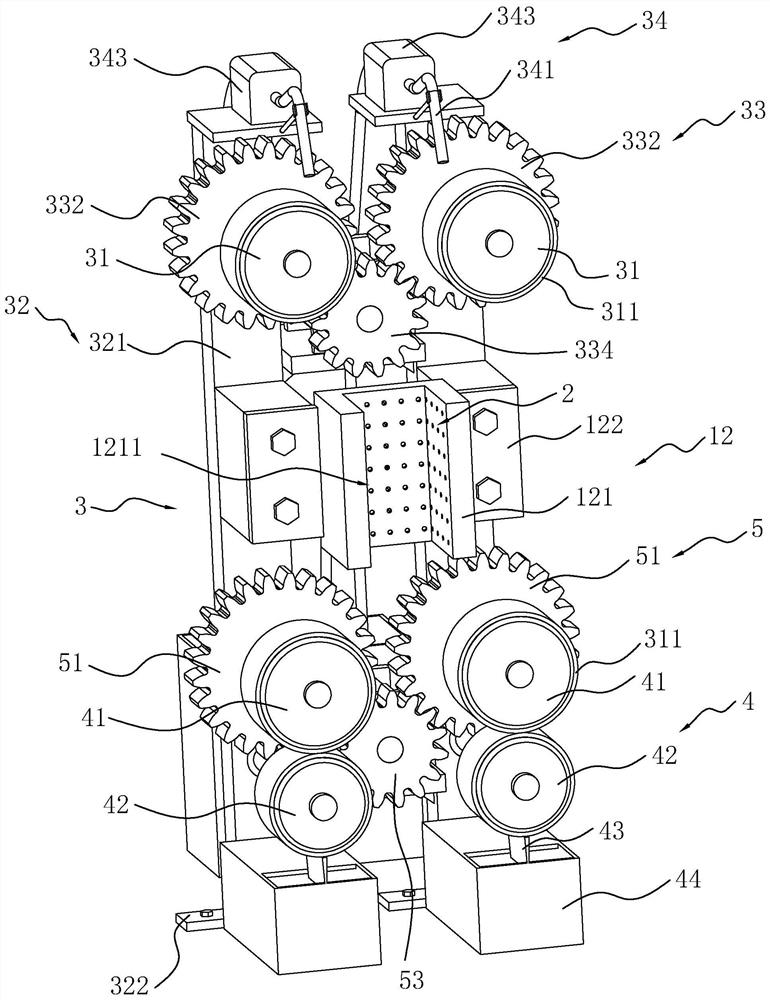

[0038] Such as figure 2 with image 3 As shown, the cross section of the guide rail 13 is square, and the guide shoe 12 is sleeved on the outer periphery of the guide rail 13. The guide shoe 12 includes a flexible part 121 that is slidably connected to the two sides opposite to the guide rail 13 and toward the side of the guide rail 13 toward the guide shoe 12 and The fixed part 122 that is arranged on the side of the flexible part 121 away from t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com