A kind of soft polyester fiber and preparation method thereof

A polyester fiber, soft technology, applied in the field of polyester fiber, can solve problems such as uneven stripes, and achieve the effects of good crimping performance, good elasticity and excellent comprehensive performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] A kind of preparation method of soft polyester fiber, its process is as follows:

[0046] According to the POY process, after distributing the PTT melt (intrinsic viscosity of 1.04dL / g) and PBT melt (intrinsic viscosity of 1.1dL / g) with a mass ratio of 50:50, from the same spinneret Hole m (circular) and spinneret hole n (circular) are extruded and subjected to relaxation heat treatment to obtain soft polyester fiber;

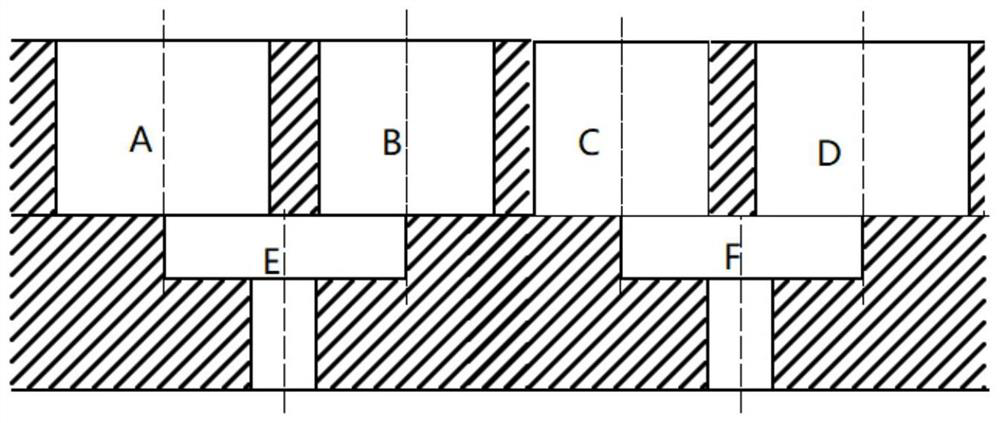

[0047] Among them, such as figure 1 As shown, the distribution means that the PBT melt is distributed through the distribution hole A, and the PTT melt is distributed into the spinneret hole m through the distribution hole B, and the PBT melt is distributed through the distribution hole C, and the PTT melt is distributed through the distribution hole Hole D is distributed to spinneret hole n; at the inlets of distribution hole A, distribution hole B, distribution hole C and distribution hole D, the apparent viscosity difference of PTT melt and PBT melt ...

Embodiment 2

[0054] A kind of preparation method of soft polyester fiber, its process is as follows:

[0055] According to the POY process, after distributing PTT melt (intrinsic viscosity 1.02dL / g) and PBT melt (intrinsic viscosity 1.2dL / g) with a mass ratio of 50:50, from the same spinneret Hole m (circular) and spinneret hole n (circular) are extruded and subjected to relaxation heat treatment to obtain soft polyester fiber;

[0056] Wherein, the distribution refers to distributing the PBT melt through the distribution hole A, while distributing the PTT melt through the distribution hole B to the spinneret hole m, passing the PBT melt through the distribution hole C, and simultaneously distributing the PTT melt through the distribution hole D is distributed into the spinneret hole n; at the entrance of distribution hole A, distribution hole B, distribution hole C and distribution hole D, the apparent viscosity of PTT melt and PBT melt differs by 4.6%;

[0057] Distribution hole A and d...

Embodiment 3

[0063] A kind of preparation method of soft polyester fiber, its process is as follows:

[0064] According to the POY process, after distributing PTT melt (intrinsic viscosity 1.02dL / g) and PBT melt (intrinsic viscosity 1.2dL / g) with a mass ratio of 50:50, from the same spinneret Hole m (circular) and spinneret hole n (circular) are extruded and subjected to relaxation heat treatment to obtain soft polyester fiber;

[0065] Wherein, the distribution refers to distributing the PBT melt through the distribution hole A, while distributing the PTT melt through the distribution hole B to the spinneret hole m, passing the PBT melt through the distribution hole C, and simultaneously distributing the PTT melt through the distribution hole D is distributed into the spinneret hole n; at the entrance of distribution hole A, distribution hole B, distribution hole C and distribution hole D, the apparent viscosity of PTT melt and PBT melt differs by 4.7%;

[0066] Distribution hole A and d...

PUM

| Property | Measurement | Unit |

|---|---|---|

| shrinkage | aaaaa | aaaaa |

| stability | aaaaa | aaaaa |

| elastic recovery rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com