Parallel self-crimped wool-like elastic fibers and preparation method thereof

An elastic fiber, self-crimping technology, applied in the field of polyester fiber, can solve problems such as uneven stripes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] A kind of preparation method of side by side self-curling hair-like elastic fiber, its process is as follows:

[0044] On the circular spinneret I, the PTT melt (intrinsic viscosity is 1.1dL / g) is directly extruded after distribution, and POY filaments are obtained according to the POY process;

[0045] On the circular spinneret II, after the PET melt (intrinsic viscosity is 0.55dL / g) and PTT melt (intrinsic viscosity as above) with a mass ratio of 50:50 are distributed, the The wire hole m and the spinneret hole n are extruded, and the FDY wire is obtained according to the FDY process;

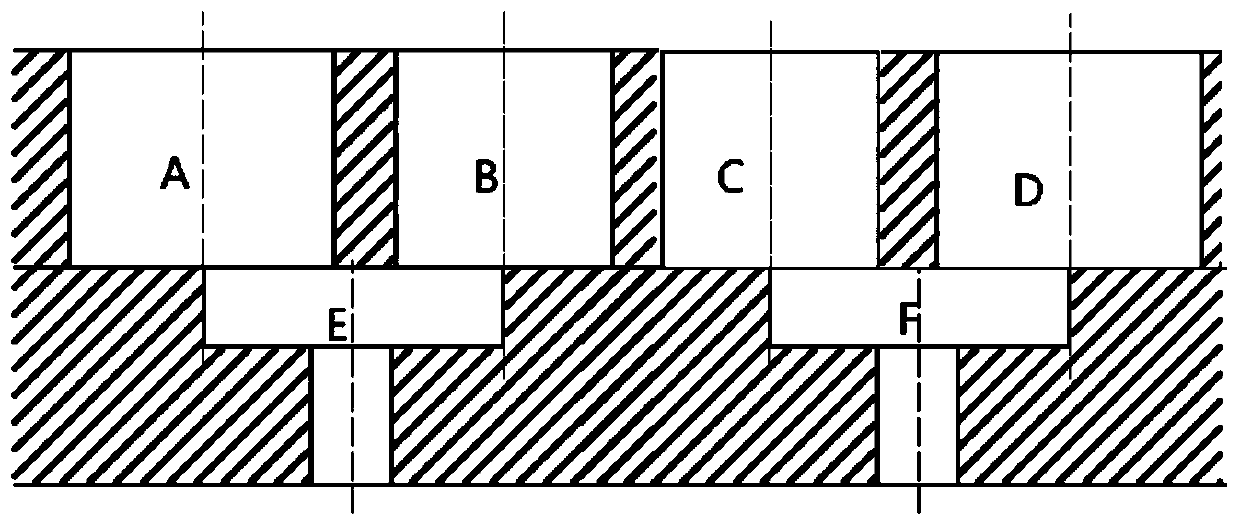

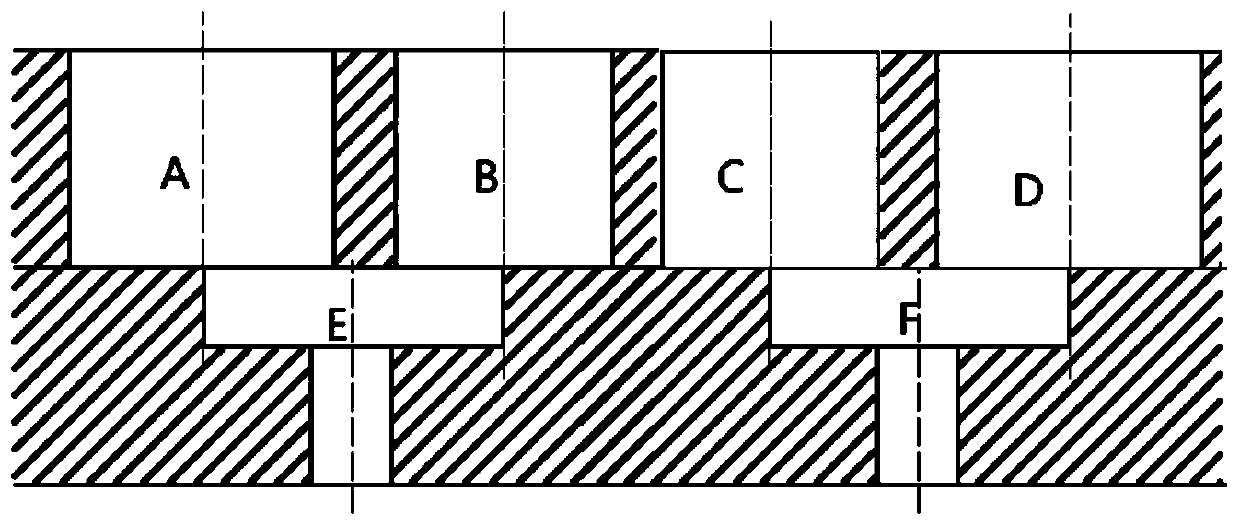

[0046] Such as figure 1 As shown, on the spinneret II, the distribution refers to distributing the PTT melt through the distribution hole A, and at the same time distributing the PET melt through the distribution hole B into the spinneret m, and distributing the PTT melt through the distribution hole C, At the same time, the PET melt is distributed to the spinneret hole n through the...

Embodiment 2

[0054] A kind of preparation method of side by side self-curling hair-like elastic fiber, its process is as follows:

[0055] On the elliptical spinneret I, the PTT melt (intrinsic viscosity is 1.06dL / g) is directly extruded after distribution, and POY filaments are obtained according to the POY process;

[0056] On the circular spinneret II, after the PET melt (intrinsic viscosity is 0.54dL / g) and PTT melt (intrinsic viscosity as above) with a mass ratio of 50:50 are distributed, the The wire hole m and the spinneret hole n are extruded, and the FDY wire is obtained according to the FDY process;

[0057] On the spinneret II, the distribution refers to distributing the PTT melt through the distribution hole A, and at the same time distributing the PET melt into the spinneret m through the distribution hole B, and distributing the PTT melt through the distribution hole C, and simultaneously distributing the PET The melt is distributed to the spinneret hole n through the distri...

Embodiment 3

[0065] A kind of preparation method of side by side self-curling hair-like elastic fiber, its process is as follows:

[0066] On the circular spinneret I, the PTT melt (intrinsic viscosity is 1.03dL / g) is directly extruded after distribution, and POY filaments are obtained according to the POY process;

[0067] On the circular spinneret II, after the PET melt (intrinsic viscosity is 0.5dL / g) and PTT melt (intrinsic viscosity as above) with a mass ratio of 50:50 are distributed, the The wire hole m and the spinneret hole n are extruded, and the FDY wire is obtained according to the FDY process;

[0068] On the spinneret II, the distribution refers to distributing the PTT melt through the distribution hole A, and at the same time distributing the PET melt into the spinneret m through the distribution hole B, and distributing the PTT melt through the distribution hole C, and simultaneously distributing the PET The melt is distributed to the spinneret hole n through the distribut...

PUM

| Property | Measurement | Unit |

|---|---|---|

| shrinkage | aaaaa | aaaaa |

| stability | aaaaa | aaaaa |

| elastic recovery rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com