A drying system for non-woven fabric processing

A drying system and non-woven fabric technology, applied in the cleaning method using tools, drying, dry goods handling, etc., can solve the problems of easy winding and rowing, and speed up the drying speed of non-woven fabrics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

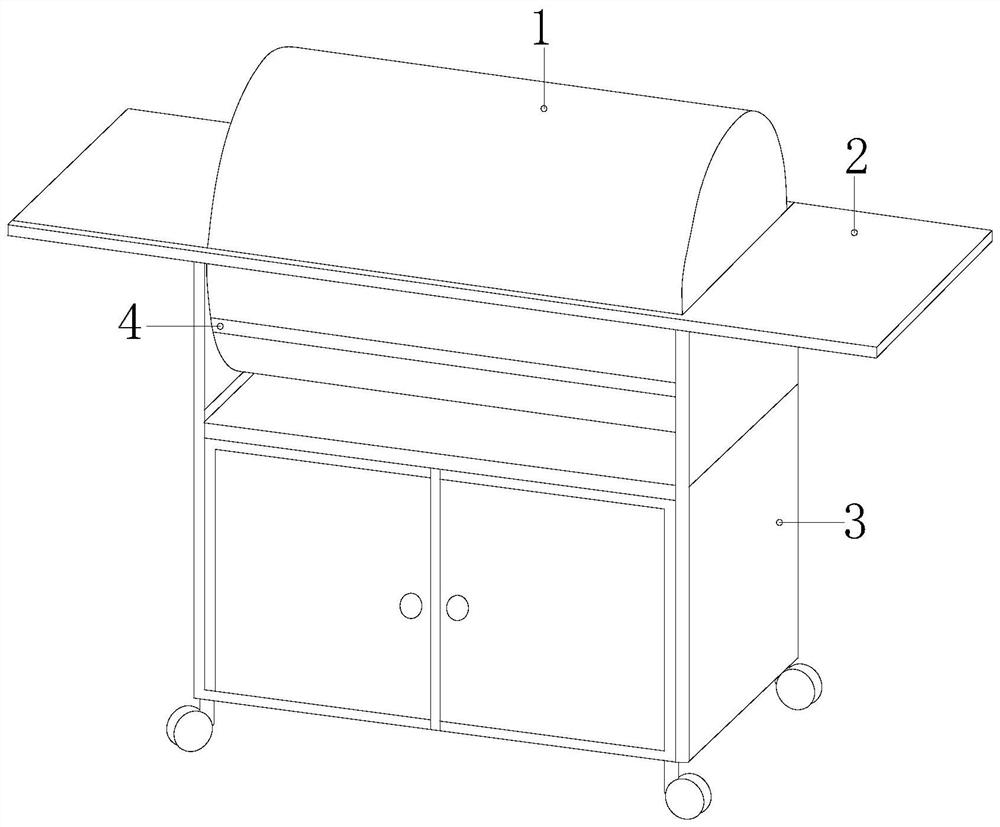

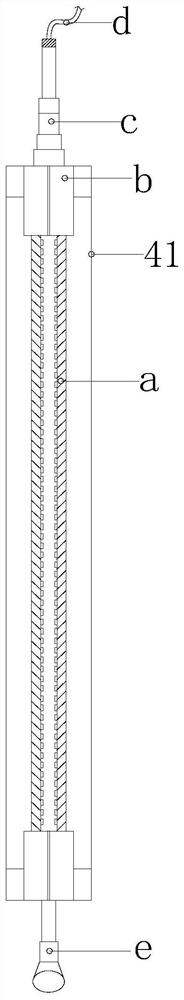

[0024] Such as Figure 1-Figure 3 As shown, the present invention provides a drying system for non-woven fabric processing, the structure of which includes a drying cylinder 1, a baffle plate 2, a driving body 3, and a cloth outlet groove 4. The signal end of the drying cylinder 1 is connected to the The driving body 3 is electrically connected, and the drying cylinder 1 is provided with a cloth outlet groove 4 with a closed cover, and the baffle plate 2 is fixed on the drying cylinder 1 and welded together with the outer casing of the driving body 3 , the static elimination system 41 is provided in the cloth outlet 4, and the static elimination system 41 is composed of an electrostatic ion bar a, a mounting base b, a high-voltage connector c, a high-voltage connection d, and a grounding terminal e. The electrostatic ion bar a passes through The mounting base b is fixed, one end of the electrostatic ion bar a is connected to a grounding terminal e, and the other end is electri...

Embodiment 2

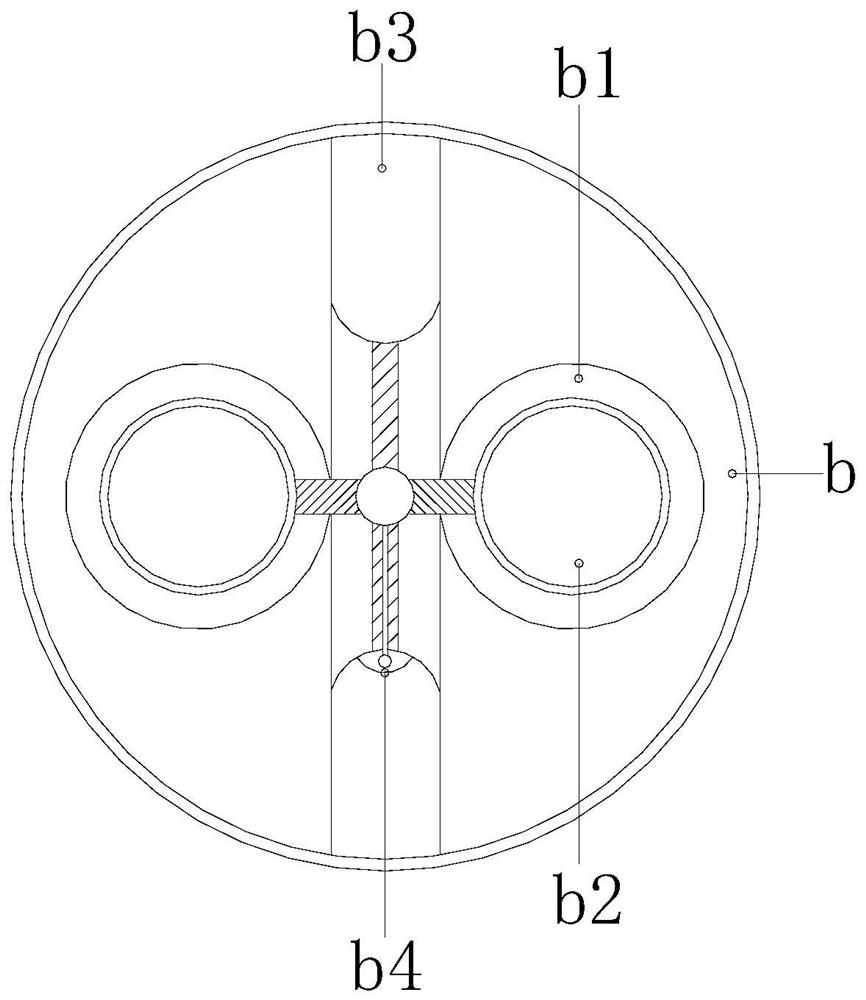

[0026] Such as Figure 4-5 As shown, a swing system is used to cooperate with the inner turntable b2 between the two symmetrical grooves b4, wherein the swing system is provided with a spring pull cord b41, a slide rail b42, a guide wheel b43, and a tension spring b44. The rope b41 is connected to the guide wheel b43, and the guide wheel b43 is movably fitted on the slide rail b42. The two tension springs b44 are symmetrical with respect to the guide wheel b43, and the tension spring b44 is connected to the inner turntable b2 by welding. The above-mentioned ion head a2 is in contact with the non-woven fabric, so that the positively opposite ion heads a2 adopt tooth meshing, and through the provided swing system, it is connected to the inner turntable b2 that rotates synchronously with the electrostatic ion bar a by means of a tension spring b44. Combined with slide rail b42, guide wheel b43 and spring pull cord b41, it provides effective conditions for the reset of ion head a2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com