A Gear Fault Diagnosis Method Based on Scalable Displacement Hyperdisk

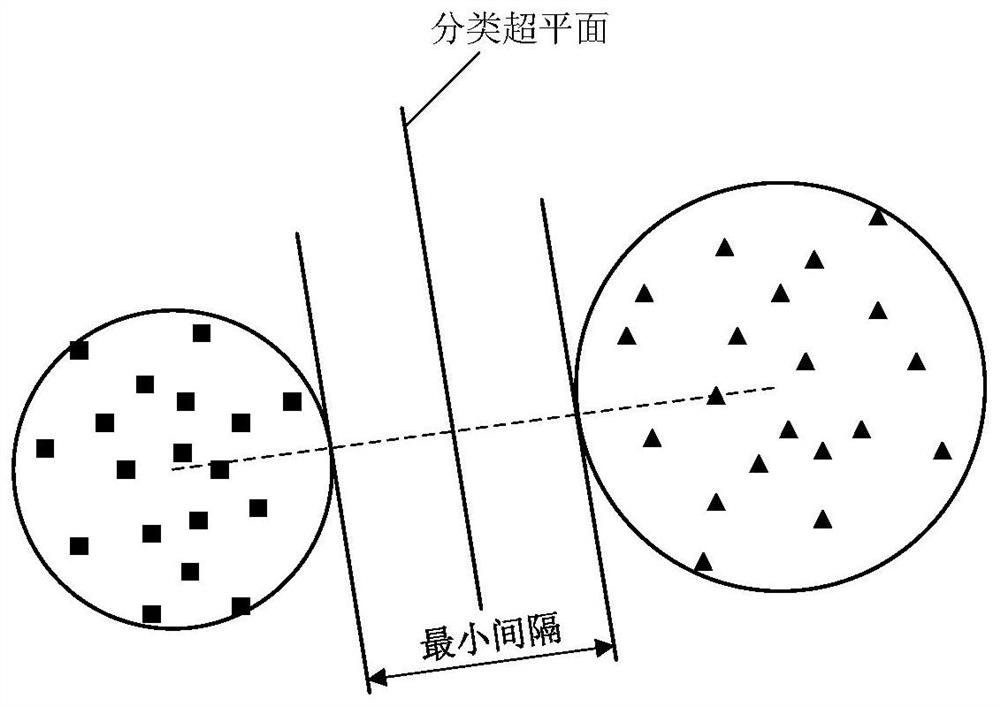

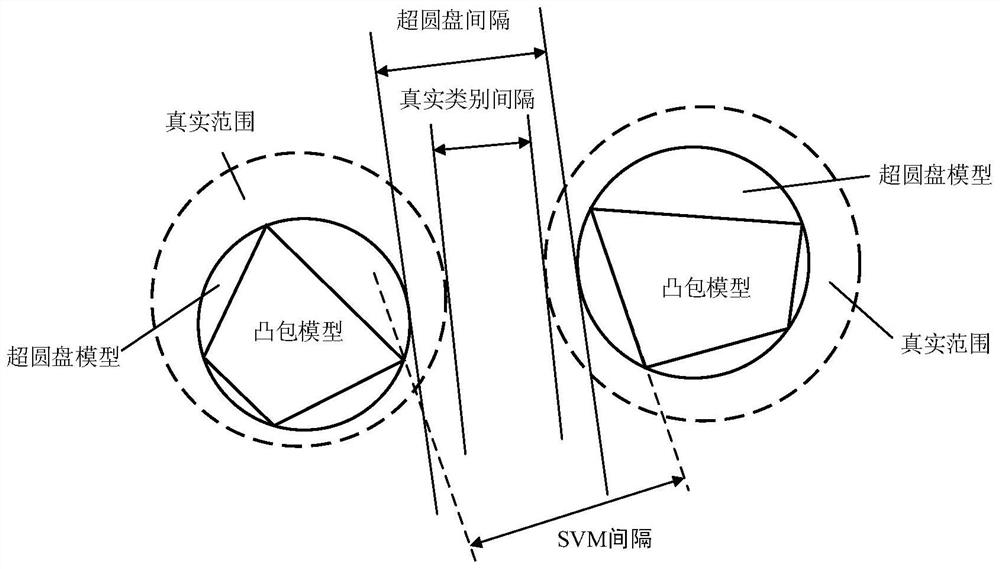

A fault diagnosis and disc technology, applied in the testing of mechanical components, testing of machine/structural components, instruments, etc., can solve the problem of more reasonable estimation of the impact of compactness or looseness on category distribution, and the impact of outliers on classification accuracy, etc. problems, to achieve the effect of improving generalization ability and robustness, and improving accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0059] The faulty object in the embodiment of the present invention can be a gear, but not limited to a gear. After reading the present invention, the gear fault diagnosis method based on the telescopic displacement ultra-disc adopted by those skilled in the art according to the method of the present invention belongs to the protection of the present invention. scope. In the specific embodiment, the gear is used as a preferred embodiment to explain the Fangming method, which is not a limiting condition of the present invention. In addition, the present invention does not require strict implementation of the sequence of steps in the following drawings, and any method that can achieve the purpose of fault diagnosis according to the above method belongs to the protection scope of the present invention.

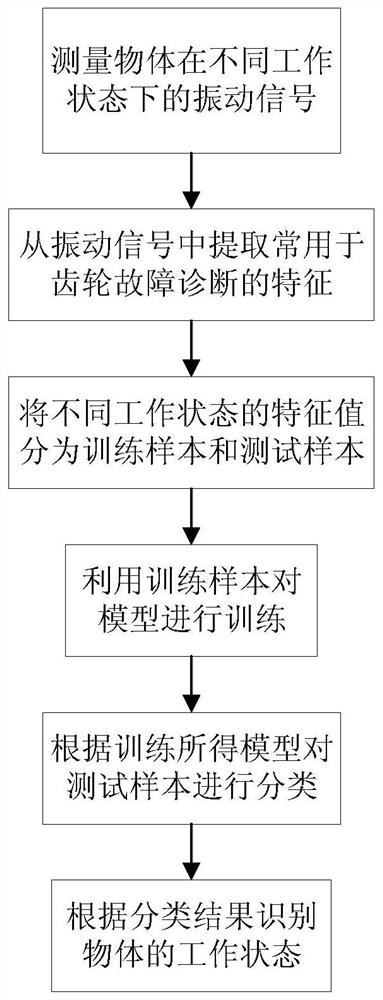

[0060] refer to image 3 , the present invention proposes a gear fault diagnosis method based on a telescopic shift super disc, which includes the following steps:

[0061] 1) ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com