Rapid optimization method of cycloidal gear tooth profile modification coefficient

A technology of cycloidal gear teeth and optimization method, applied in the field of cycloidal gear, can solve the problems of increasing optimization time, long optimization time, and no given range, and achieves the effect of speeding up the optimization speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] The present invention will be described in detail below according to the accompanying drawings and preferred embodiments, and the purpose and effect of the present invention will become clearer. It should be understood that the specific embodiments described here are only used to explain the present invention, and are not intended to limit the present invention.

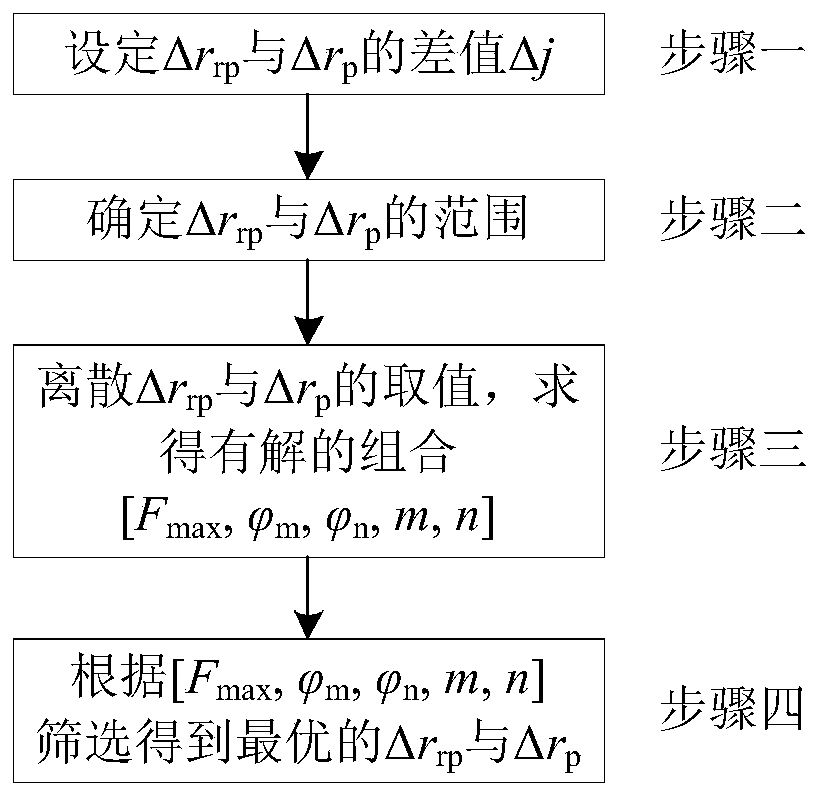

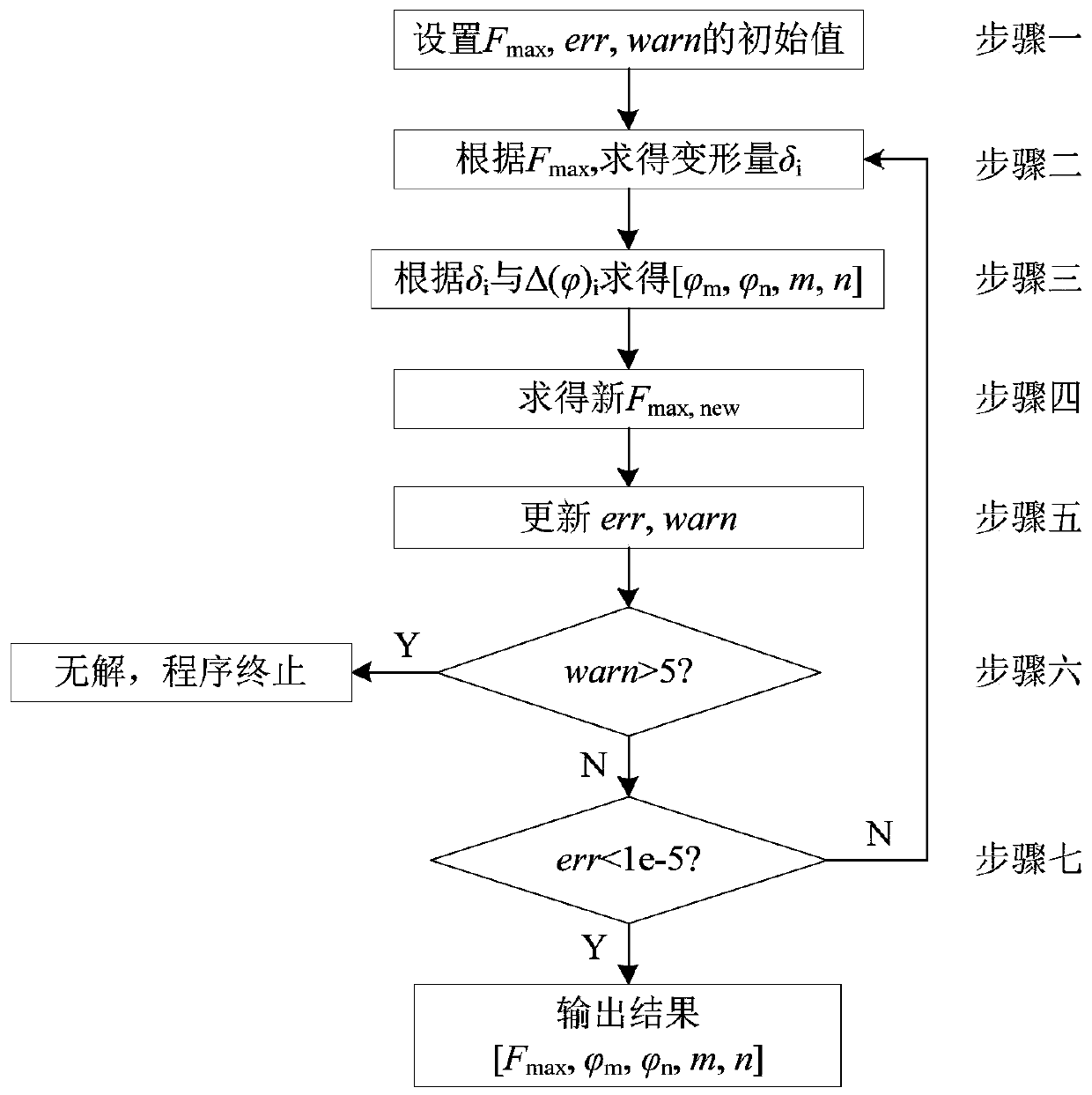

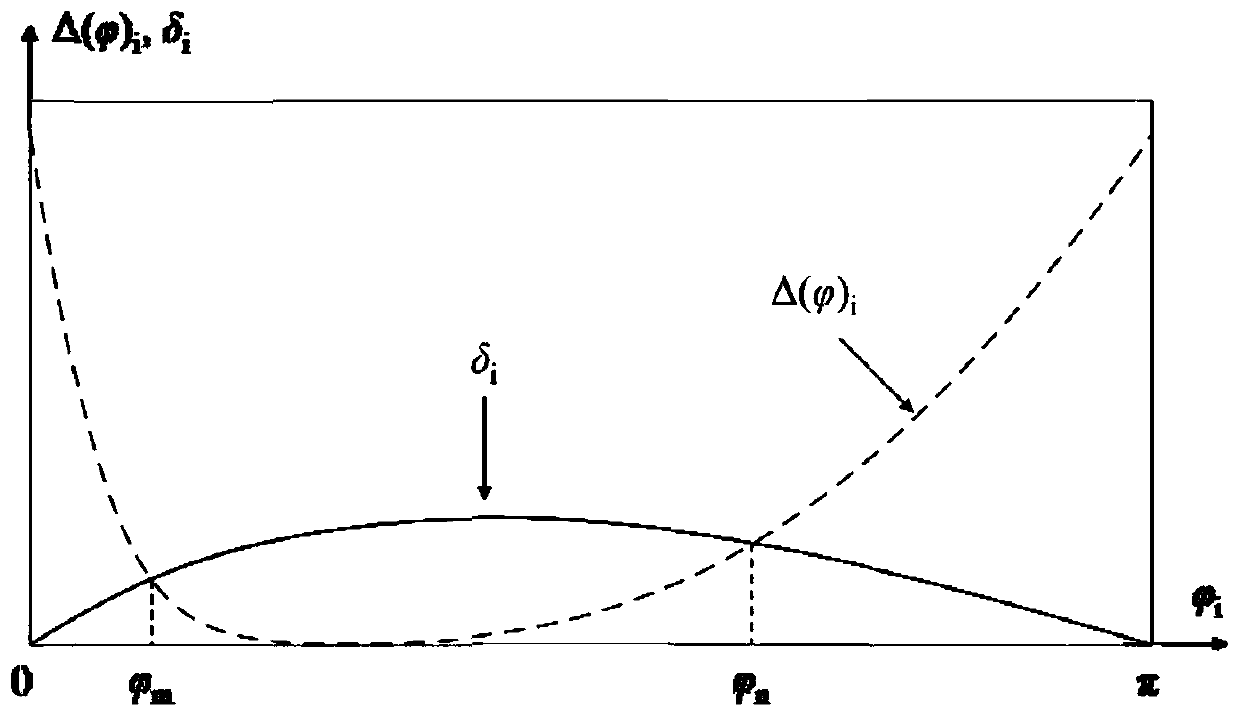

[0045] The technical idea of the present invention is: the rapid optimization method of the tooth profile modification coefficient of the cycloid wheel of the present invention mainly includes two algorithm ideas, the first is to utilize the initial meshing gap between the cycloid wheel and the pin wheel exist is the minimum value and the minimum value in the [0, π] interval, through the Derivation operation is performed to reduce the tooth profile modification coefficient Δr p and Δr rp The value range of , reduce and filter the optimal tooth profile modification coefficient Δr p and Δr rp The calcul...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com