Cascade type refrigerating and heating energy-saving system

An energy-saving system and cascading technology, which is applied in the field of heating and cooling energy saving, can solve the problems of low energy efficiency, narrow temperature environment range, large compressor load, etc., and achieve the goal of improving low-temperature heating performance, improving low-temperature adaptability, and stable system operation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

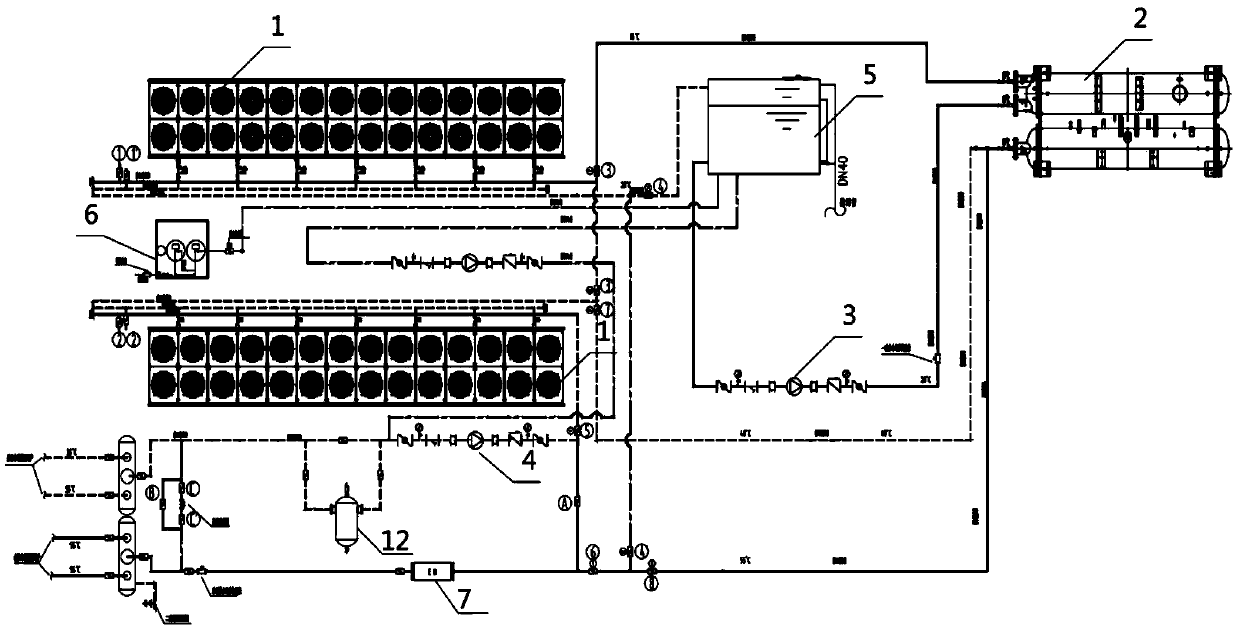

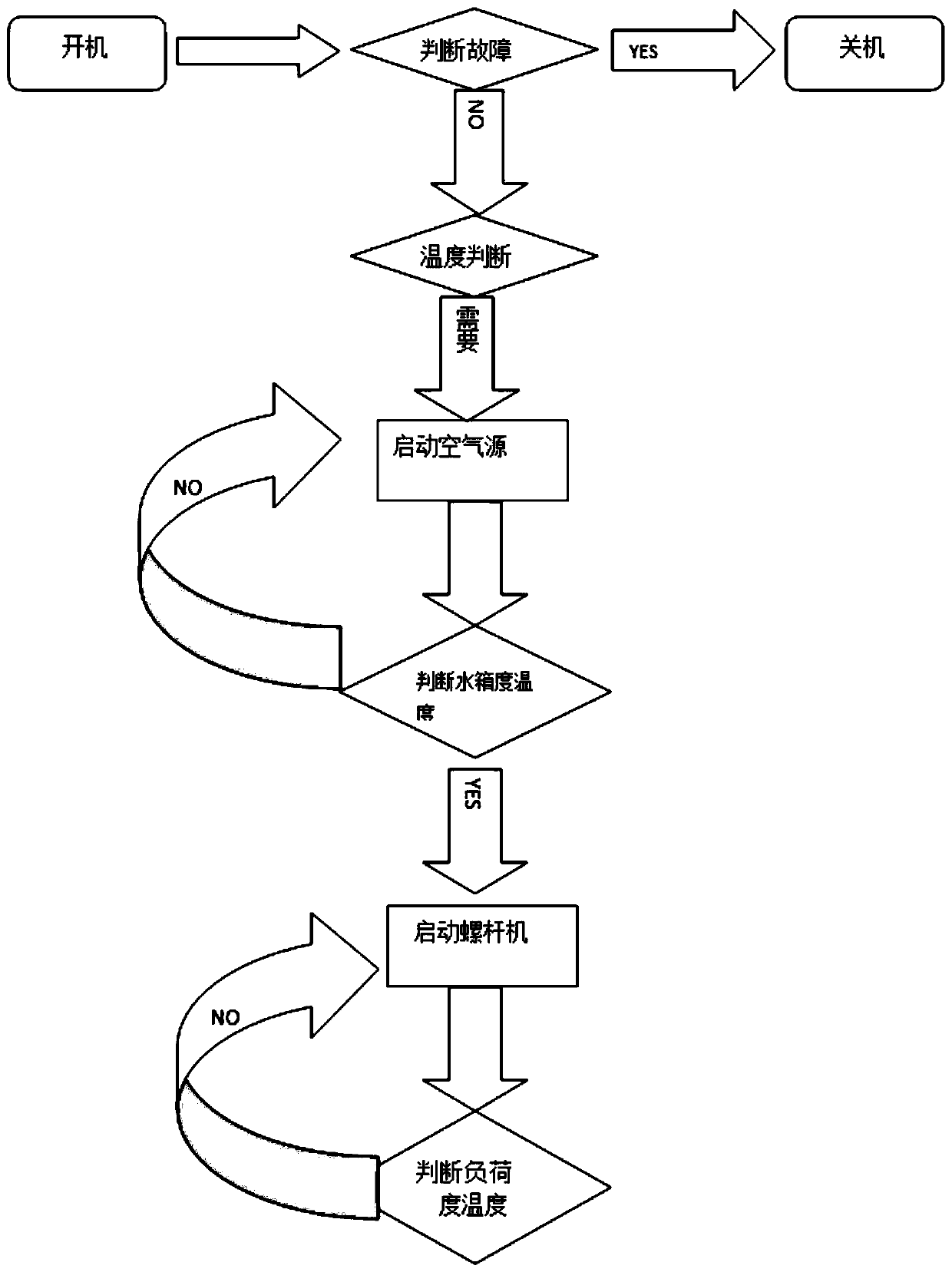

[0015] Such as figure 1 with image 3 As shown, this embodiment discloses a cascade cooling and heating energy-saving system, which includes two sets of air source modules 1, a screw heat source unit 2, a screw heat source unit water supply pump 3, an air conditioning system circulating pump 4, and a thermal buffer water tank 5. Complete water softener 6 and heating remote transmission summary table 7.

[0016] Among them, seven air source modules are responsible for producing 20℃ low-temperature water for the evaporative side heat source of screw heat source unit 2, and the other seven air source modules are installed on the return water side of the terminal system to conduct water supply to the condenser of screw heat source unit 2 When heated to 40°C, one screw heat source unit 2 is provided in this embodiment, and the condenser outlet water temperature of the screw heat source unit 2 is 55°C, and the return water temperature is 35°C.

[0017] In this embodiment, the capacity e...

Embodiment 2

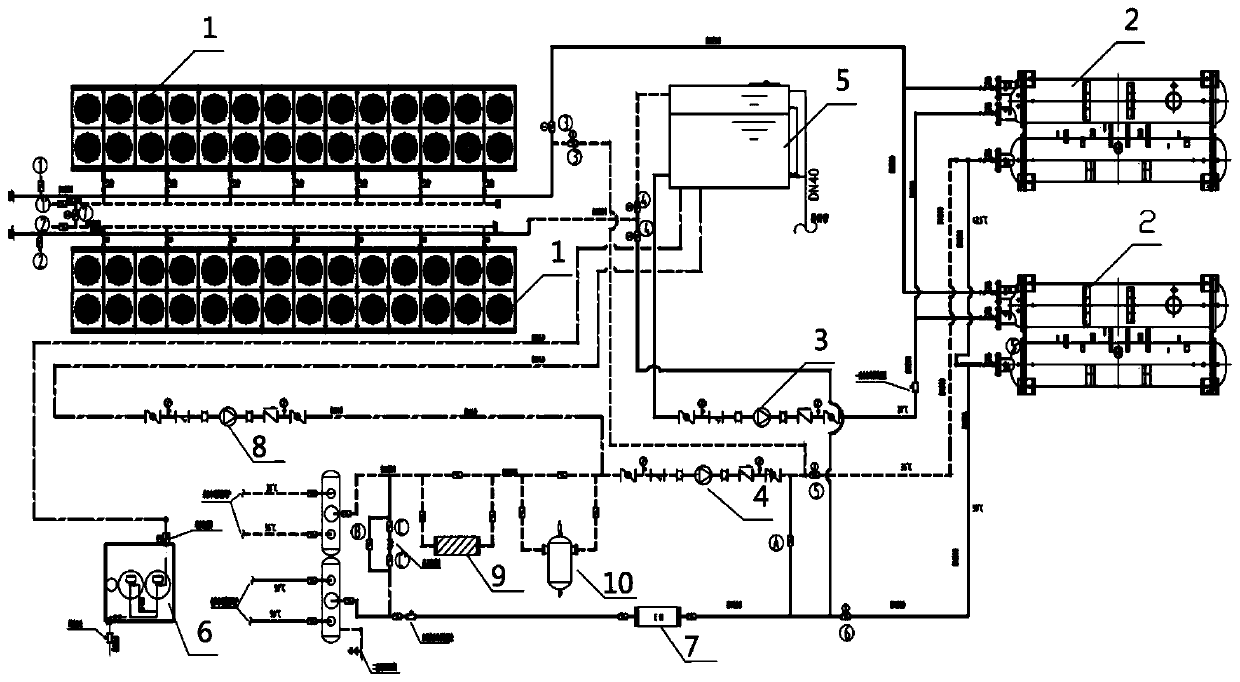

[0020] Such as figure 2 with image 3 As shown, the cascade cooling and heating energy-saving system in this implementation includes two sets of air source modules composed of several air source heat pumps 1, two screw heat source units 2, screw heat source unit water supply pumps 3, air conditioning system circulating pumps 4. Thermal buffer water tank 5, full-process water softener 6, heating remote transmission summary table 7, air source module heat storage circulation pump 8, coarse filter 9, and micro-bubble exhaust decontamination device 10; Two sets of air source modules 1 and two screw heat source units 2 are set correspondingly.

[0021] This implementation uses air as the heat source and water as the heat carrier during heating operation, and circulates through the thermal buffer water tank 5, screw heat source unit water supply pump 3, two screw heat source units 2, air source module 1, and connected pipelines. When the air source module 1 is working, the heat energ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com