Special material for polypropylene combined cap and outer cap for infusion container

An infusion container, polypropylene technology, applied in the field of pharmaceutical packaging, can solve the problems of increasing melt viscosity, large opening force of the pull ring, difficult to process and form, and achieve the effects of lowering melting point, easy opening, and improving anti-aging performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

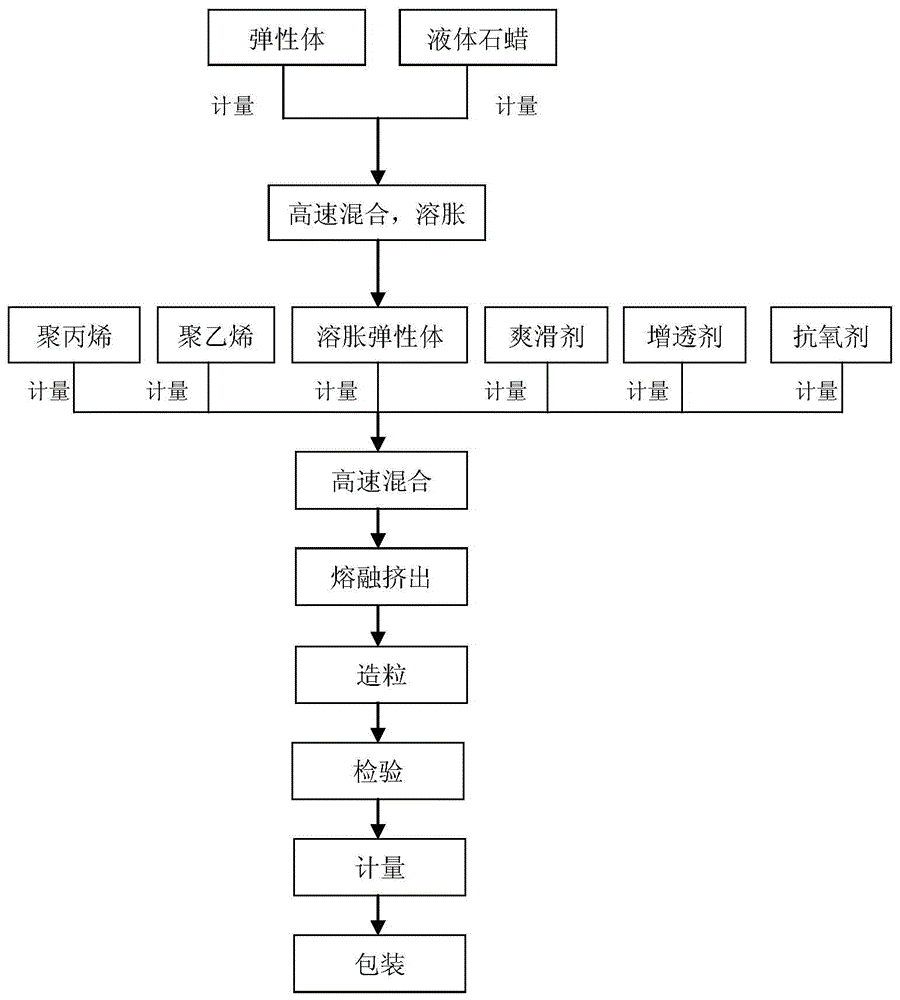

Method used

Image

Examples

Embodiment 1

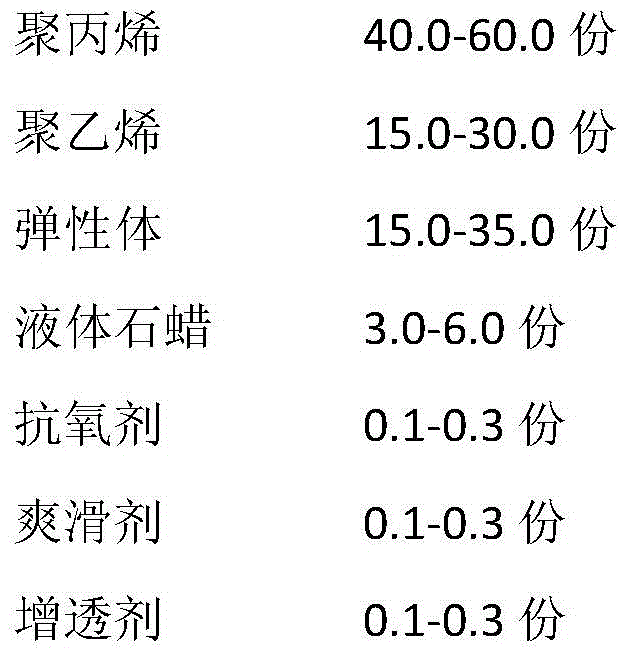

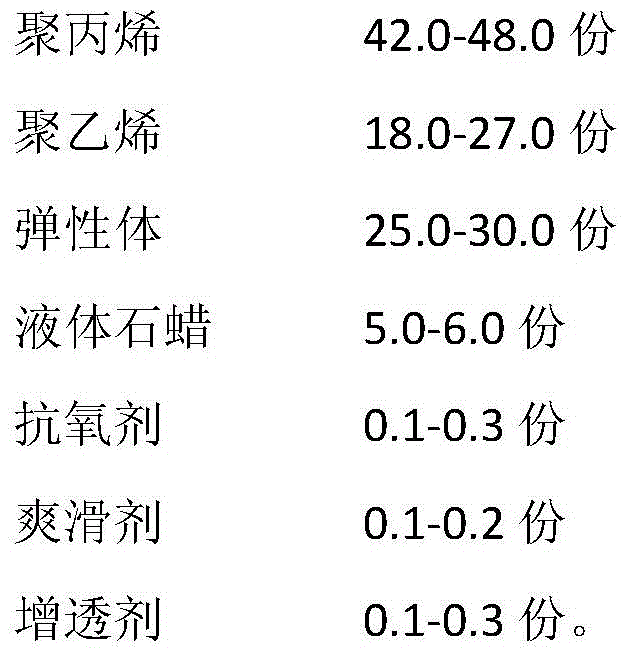

[0034] Take 25Kg of POE and 5Kg of medical grade white oil, mix at a high speed of 2000r / min for 5 minutes, then leave for 2 hours to obtain a swelling elastomer.

[0035] Take 48kg of polypropylene, 22Kg of polyethylene, 0.1Kg of erucamide, 0.1Kg of anti-reflection agent Millad3988 and 0.3Kg of antioxidant (a mixture of antioxidant 1010 and antioxidant 168 in a mass ratio of 2:1) and 30Kg of the above-mentioned swelling elastomer was mixed at a high speed of 2000r / min for 5 minutes at a temperature of 170°C-190°C, and then extruded and granulated to prepare a special material for the outer cover of the polypropylene combination cap of the infusion container.

Embodiment 2

[0037] Take 28Kg of the elastomer and 5.6Kg of medical grade white oil, mix at a high speed of 2000r / min for 5 minutes, then leave it for 2 hours to obtain the swollen elastomer.

[0038]Take 46.4kg of polypropylene, 20Kg of polyethylene, 0.15Kg of erucamide, 0.15Kg of anti-reflection agent Millad3988 and 0.3Kg of antioxidant (mixture of antioxidant 1010 and antioxidant 168 in a mass ratio of 2:1) And 33.6Kg of the above-mentioned swelling elastomer was mixed at 170°C-190°C at a high speed of 2000r / min for 5 minutes, and then extruded and granulated to prepare the special material for the outer cover of the polypropylene combination cap of the infusion container.

Embodiment 3

[0040] Take 30Kg of the elastomer and 6Kg of medical grade white oil, mix at a high speed of 2000r / min for 5 minutes, then leave it for 2 hours to obtain the swollen elastomer.

[0041] Take 46kg of polypropylene, 18Kg of polyethylene, 0.2Kg of erucamide, 0.3Kg of anti-reflection agent Millad3988 and 0.3Kg of antioxidant (mixture of antioxidant 1010 and antioxidant 168 at a mass ratio of 1:1) And 36Kg of the above-mentioned swelling elastomer was mixed at 170°C-190°C at a high speed of 2000r / min for 5 minutes, and then extruded and granulated to prepare the special material for the outer cover of the polypropylene combination cap of the infusion container.

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile load | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com