A kind of azide propellant with excellent low temperature adaptability and preparation method thereof

A propellant and plasticizer technology, applied in the field of azide propellant, can solve the problems of poor low temperature adaptability, unfavorable for high-performance strategic and tactical missiles, etc. effect of length

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

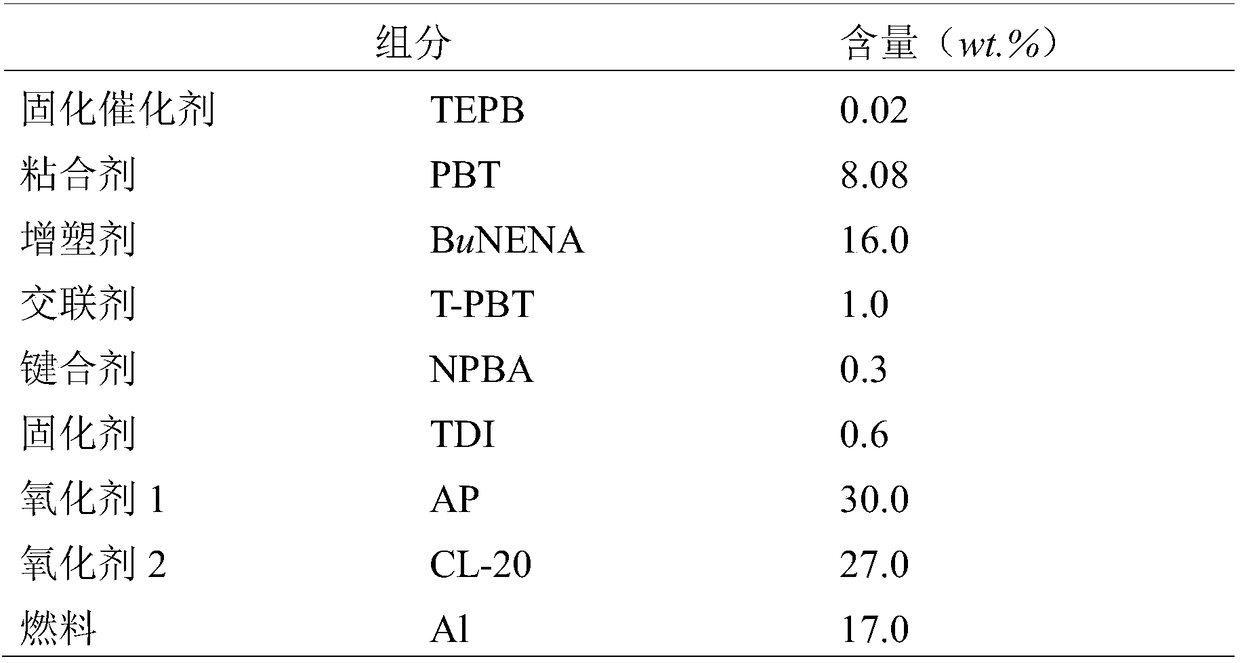

[0041] Table 1 Propellant Composition

[0042]

[0043] The propellant was prepared according to the composition and percentage shown in Table 1 above, and the test results showed that the performance of the prepared propulsion was as follows:

[0044] 1. Propellant T g = -65.0°C;

[0045] 2. The low temperature adaptability of the propellant is shown in Table 2;

[0046] 3. Measured specific impulse I of propellant sp : 256.0s (6.86MPa).

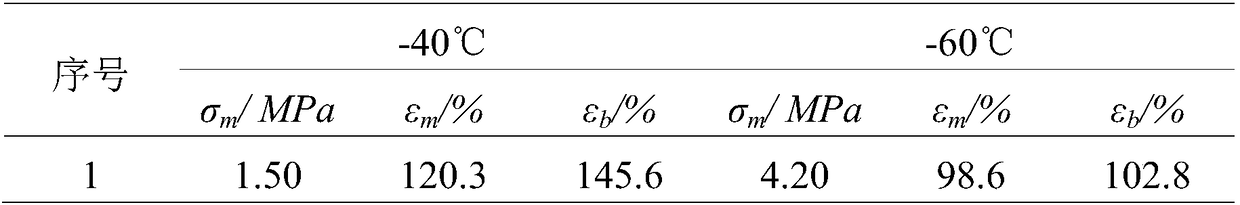

[0047] Table 2 is prepared by the low temperature adaptability of the propellant shown in Table 1

[0048]

Embodiment 2

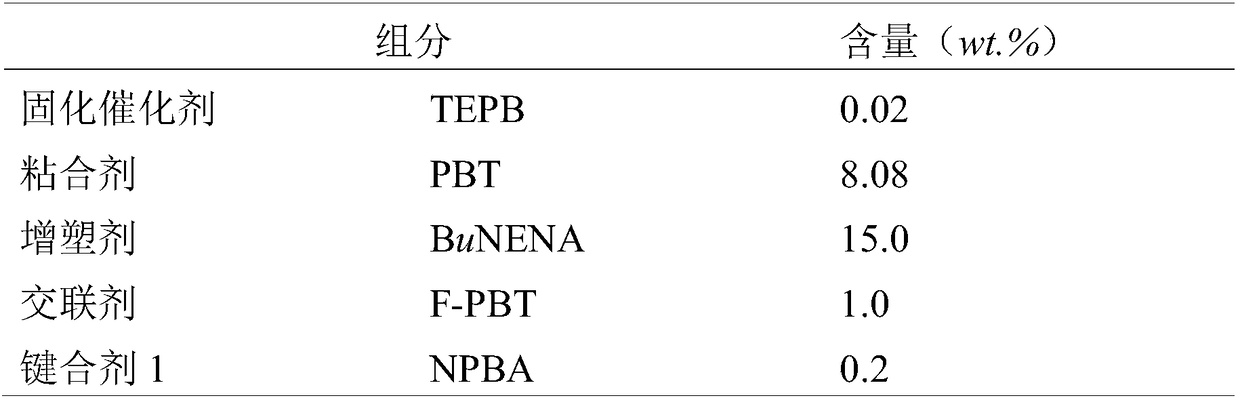

[0050] Table 3 Propellant Composition

[0051]

[0052]

[0053] Propellants were prepared with the composition and percentages shown in Table 3 above, and the test results showed that the performance of the prepared propulsion was as follows:

[0054] 1. Propellant T g = -66.0°C;

[0055] 2. The low temperature adaptability of the propellant is shown in Table 4;

[0056] 3. Measured specific impulse I of propellant sp : 255.5s (6.86MPa).

[0057] Table 4 is prepared by the low temperature suitability of the propellant shown in Table 3

[0058]

Embodiment 3

[0060] Table 5 Propellant Composition

[0061]

[0062]

[0063] The propellant was prepared according to the composition and percentage shown in Table 5 above, and the test results showed that the performance of the prepared propulsion was as follows:

[0064] Propellant properties

[0065] 1. Propellant T g =-64.0°C;

[0066] 2. The low temperature adaptability of the propellant is shown in Table 6;

[0067] 3. Measured specific impulse I of propellantsp : 253.8s (6.86MPa).

[0068] Table 6 is prepared by the low temperature suitability of the propellant shown in Table 5

[0069]

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com