A polyether solid propellant with ultra-low glass transition temperature and preparation method thereof

A technology of glass transition temperature and solid propellant, which can be used in offensive equipment, explosive processing equipment, and the generation of compressed gas.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

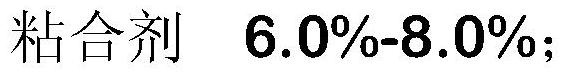

Method used

Image

Examples

preparation example Construction

[0040] The preparation process of the solid propellant provided by the embodiment of the present invention includes: preparing raw materials according to the above-mentioned raw material formula, using a vertical or horizontal mixer for mixing, and using a vacuum pouring system to realize the production of engine grains; during preparation, (1) the mixer The temperature of the water bath was set between 30 and 35°C. Adhesives, plasticizers, chain extenders, fuels, crosslinking agents, chain extenders, bonding agents and curing catalysts are premixed before mixing. After the premixed materials are added to the mixing pot, explosives and perchloric acid are added in sequence. Ammonium (AP), curing agent; and then mixed, the mixing time is between 80-120min, and the speed of the mixer is between 100-150r / min. (2) After mixing evenly, use the vacuum pouring system to pour the propellant slurry into the engine casing or various molds. (3) Put the poured engine or various molds int...

Embodiment 1

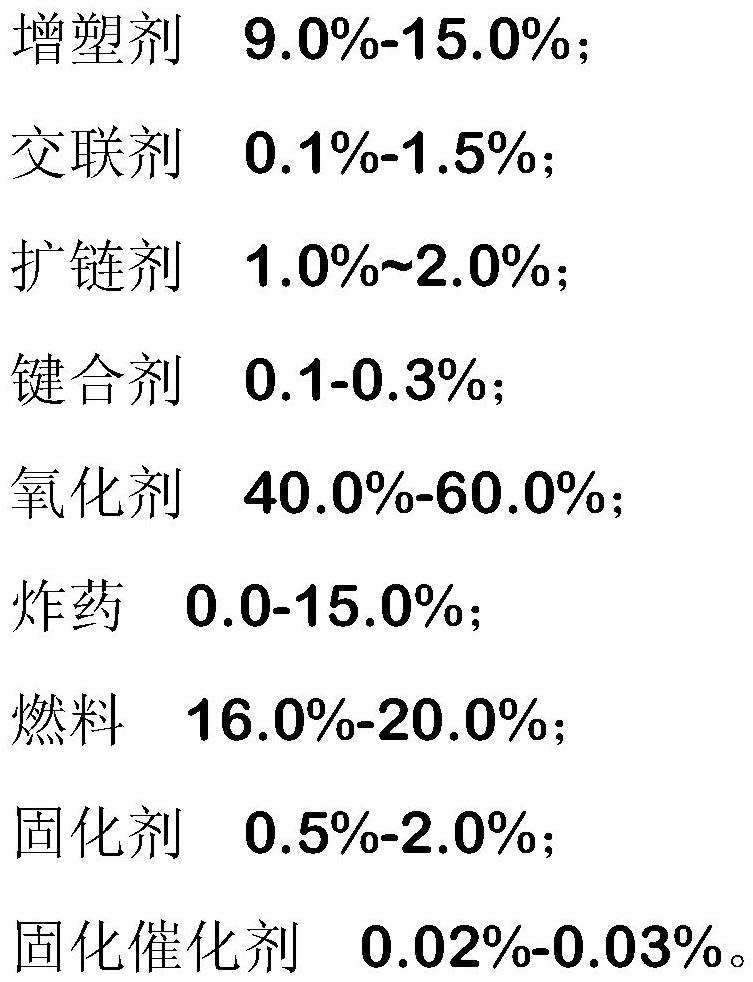

[0045] (1) The propellant composition is shown in Table 1-1:

[0046] Table 1-1 Composition of propellant

[0047]

[0048] (2) Propellant properties:

[0049] 1. Propellant T g = -93.0°C;

[0050] 2. The mechanical properties of the propellant are shown in Table 1-2;

[0051] Table 1-2 Mechanical properties of propellants

[0052]

Embodiment 2

[0054] (1) The propellant composition is shown in Table 2-1:

[0055] Table 2-1 Composition of propellants

[0056]

[0057]

[0058] (2) Propellant properties:

[0059] 1. Propellant T g = -92.2°C;

[0060] 2. The mechanical properties of the propellant are shown in Table 2-2:

[0061] Table 2-2 Mechanical properties of propellants

[0062]

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com