A low temperature heating and mixing device for urea scr system

An SCR system, heating and mixing technology, applied in the direction of mufflers, exhaust devices, engine components, etc., can solve the problems of increased NOx emissions, catalytic reaction hindrance, urea cannot be fully decomposed, etc., to ensure normal operation and improve low temperature adaptability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

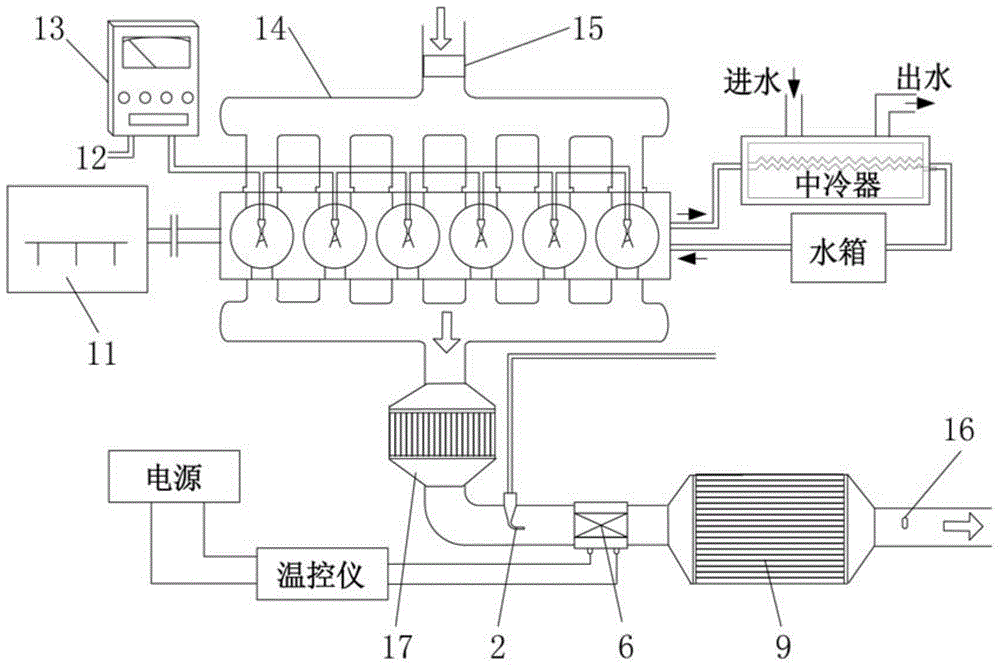

[0022] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. The following examples are used to illustrate the present invention, but are not intended to limit the scope of the present invention.

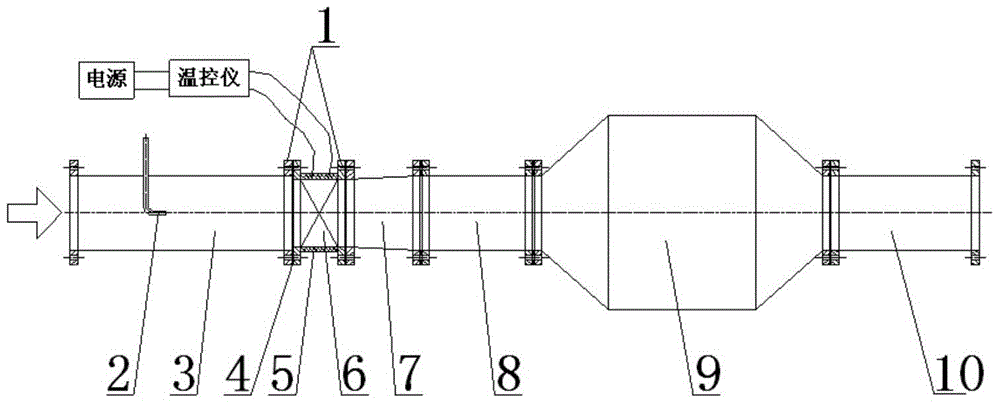

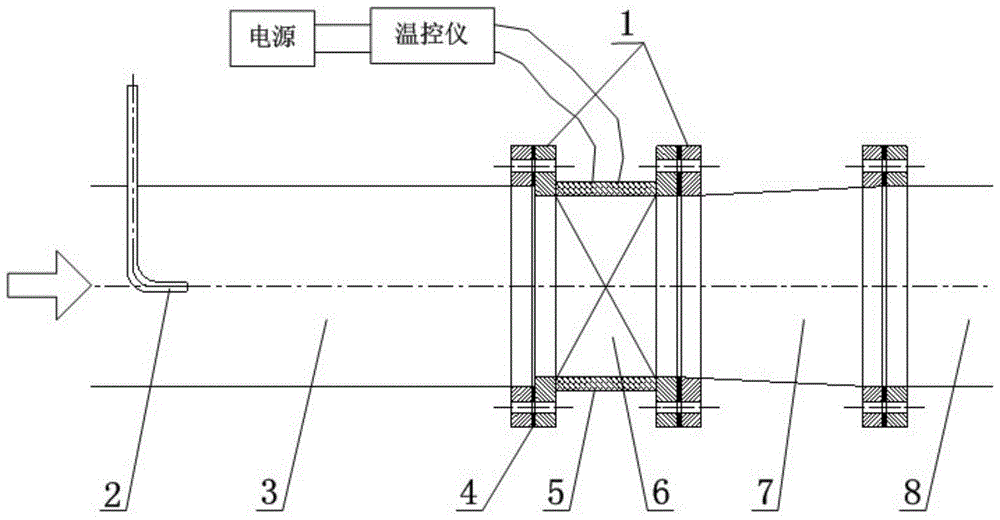

[0023] Such as Figure 1-2 As shown, the inlet and outlet of the SCR catalytic converter 9 are respectively connected to the front-end pipeline 8 of the catalytic converter and the rear-end pipeline 10 of the catalytic converter through the flange 1, and the front-end pipeline 8 of the catalytic converter is connected to a reducing pipe 7, which A mixer 6 is connected, and a heating tile 5 is installed on the periphery of the mixer 6, and the periphery of the heating tile 5 is wrapped with a heat insulating material, so as to reduce the heat loss caused by the heating tile 5 dissipating heat to the environment during heating. The mixer 6 is connected with the urea aqueous...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com