Underwater pressure-releasing sound-reflecting baffle plate

A technology of sound baffle and pressure relief, which is applied in the direction of sound-emitting devices and instruments, which can solve the problems of reduced sound insulation effect, increased weight, and increased thickness, and achieve the effect of improving sound insulation effect and reducing weight and thickness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

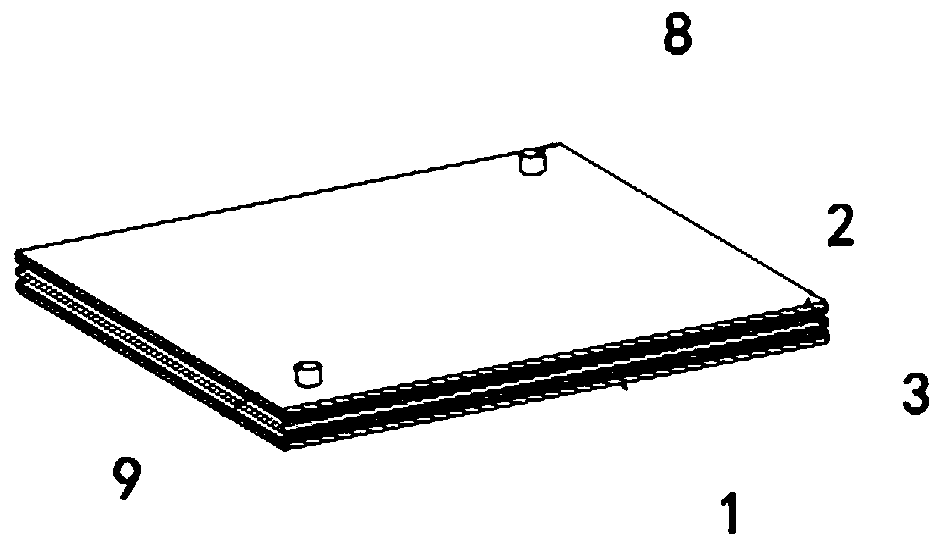

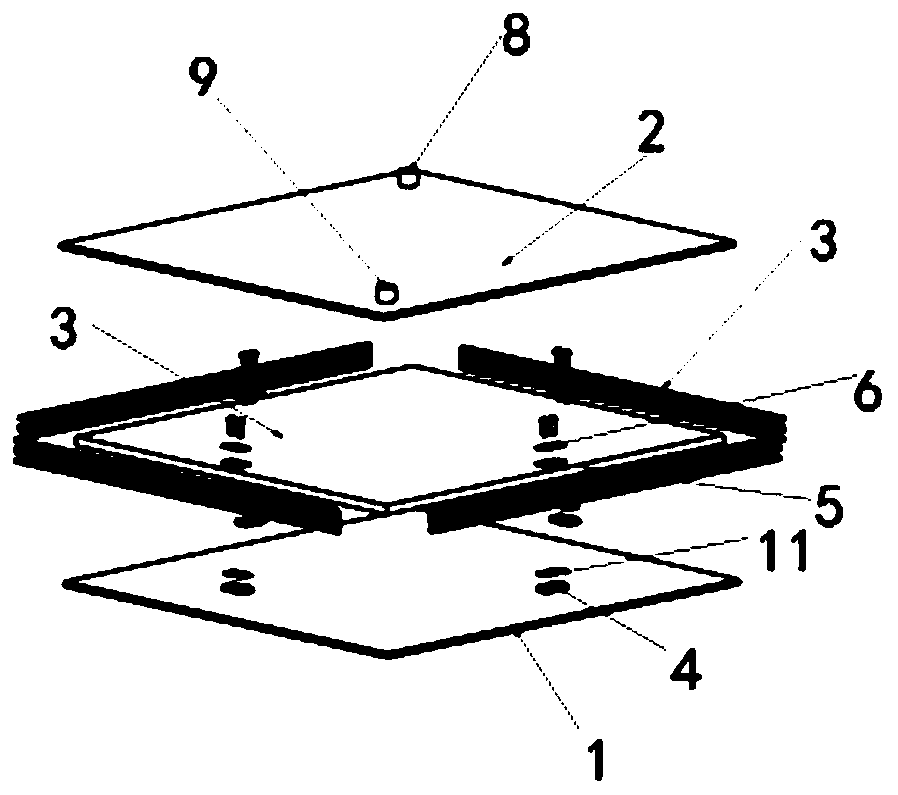

[0028] The present invention will be described in detail below with reference to the accompanying drawings and examples.

[0029] This embodiment provides an anti-acoustic baffle for underwater pressure relief, which can release pressure underwater, and solves the problem of increased weight, increased thickness, and sound insulation effect of anti-acoustic baffles in the prior art under high hydrostatic pressure. Lowering the problem.

[0030] Such as Figure 1-6 As shown, the anti-sound baffle includes: an anti-sound structure, a sealed and pressure-relief structure, a position-limiting vibration-reduction installation structure, and a liquid-filled exhaust structure; The pressure structure includes: bottom panel 1, top panel 2 and displacement compensation plate 3, the limit vibration damping installation structure includes: bottom panel welded screw hole seat 4, metal pad 6, rubber shock pad A5 and rubber shock pad B11, filling The liquid exhaust structure includes: a li...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com