Rapid bearing coarse washing device

A rough cleaning and bearing technology, applied in cleaning methods and utensils, chemical instruments and methods, and cleaning methods using liquids, etc., can solve the problems of general cleanliness and slow cleaning speed, and improve the degree of cleanliness and the speed of cleaning. , cost-effective effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described below with reference to the accompanying drawings and embodiments, and the mode of the present invention includes but not limited to the following embodiments.

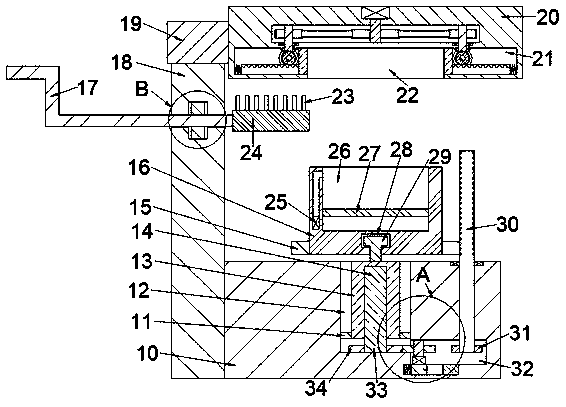

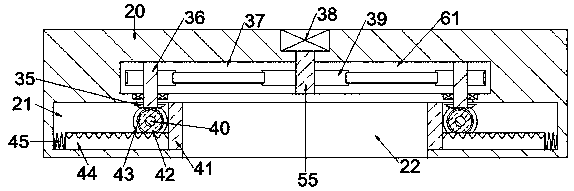

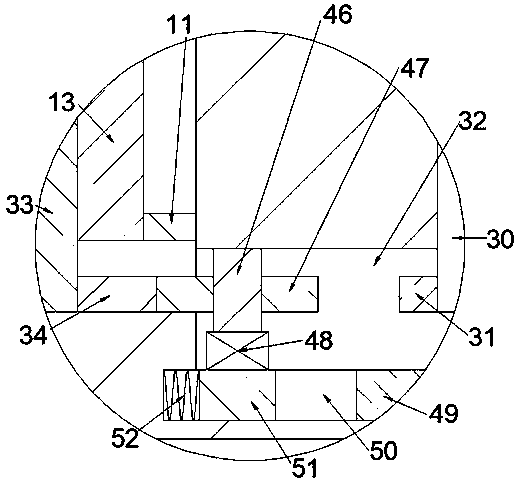

[0017] Such as Figure 1-4 As shown, a kind of quick rough cleaning equipment for bearings, comprising a working box 10 and a fixed rod 18 fixedly connected to the left end surface of the working box 10, the upper end surface of the fixed rod 18 is fixed with a fixed block 19, and the fixed block 19 The right end face is fixed with a clamping box 20, and the clamping box 20 is provided with a clamping device 61 for clamping the bearing to be roughly cleaned, and the first cavity 53 runs through the left and right sides of the fixed rod 18 , the first cavity 53 is rotated with a rotating block 54, and the fixed rod 18 is provided with a handle 17 that passes through the first cavity 53 and is keyed to the rotating block 54, so The right end surface of the turning h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com