Automatic film laminating mechanism for film laminating machine

A technology of laminating mechanism and laminating machine, applied in ceramic molding machines, auxiliary molding equipment, metal processing, etc., can solve the problems of many power devices, film damage costs, and inability to directly complete lamination, lamination and film cutting, etc. , to achieve the effect of high degree of automation, stable transmission and good attachment effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

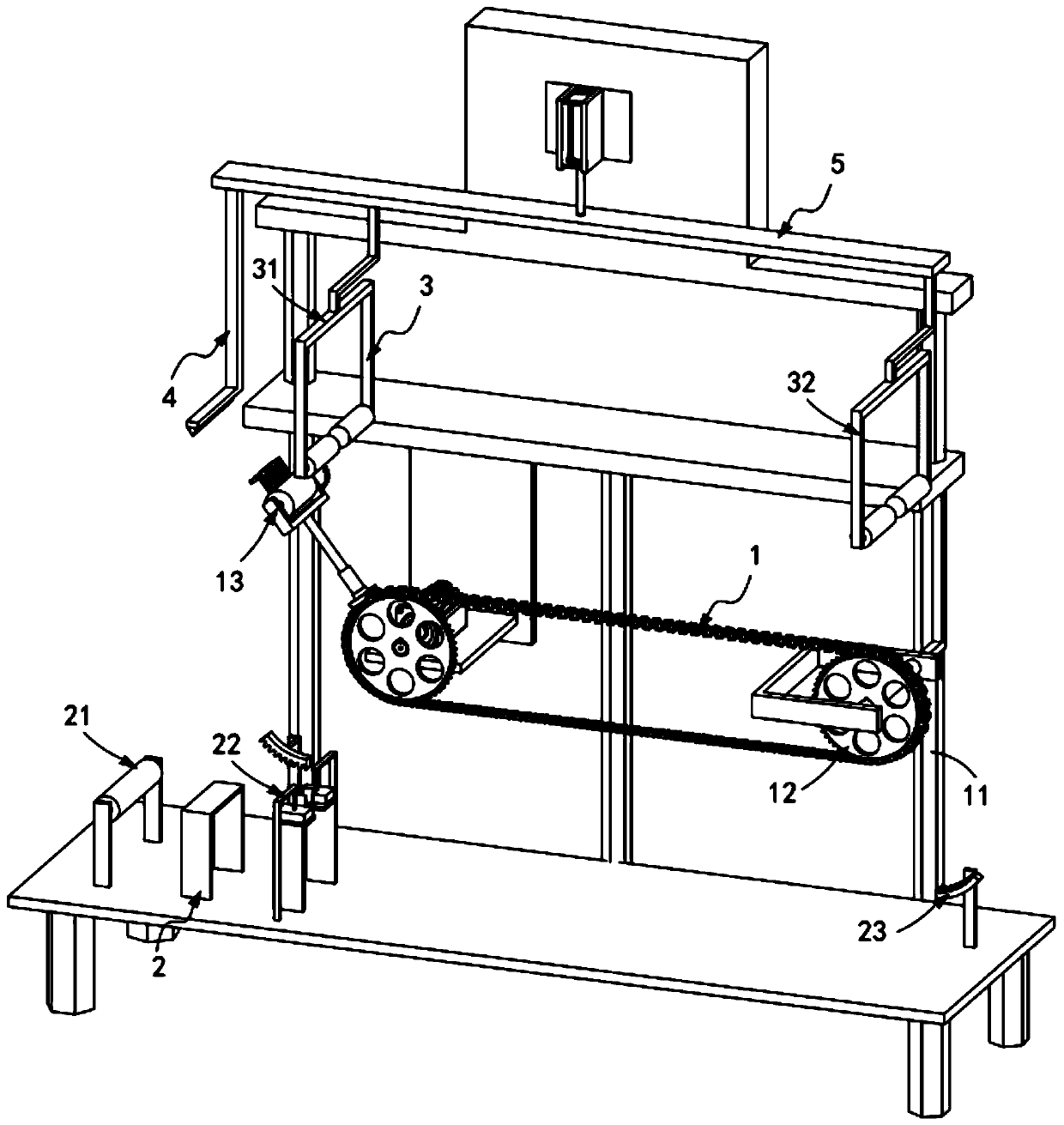

[0062] like figure 1 , Figure 9 and Figure 10 As shown, the automatic laminating mechanism for the laminating machine includes:

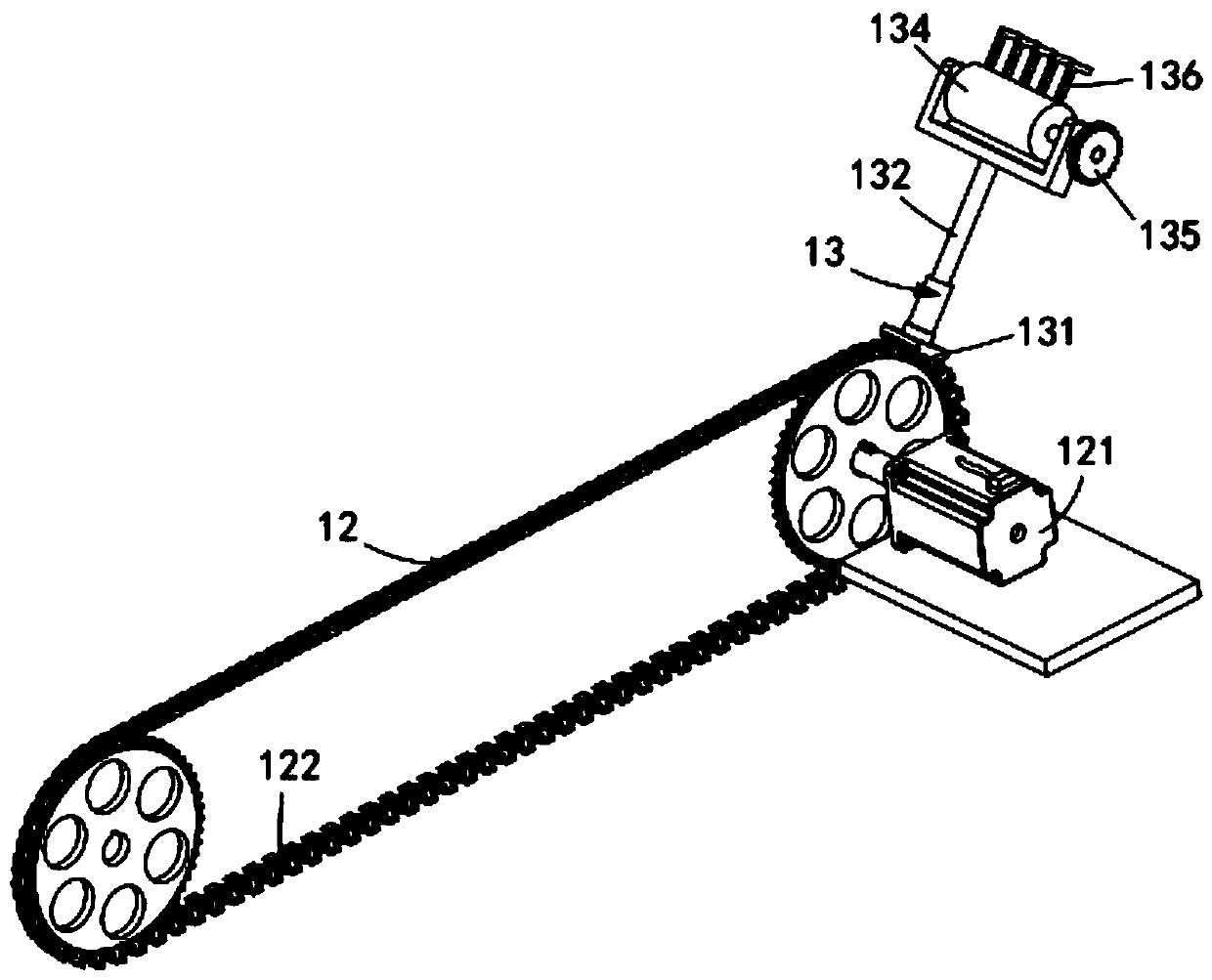

[0063] A revolving mechanism 1, the revolving mechanism 1 includes a first drive assembly 12 installed on the frame 11 and a film pulling assembly 13 driven by the first drive assembly 12 to rotate;

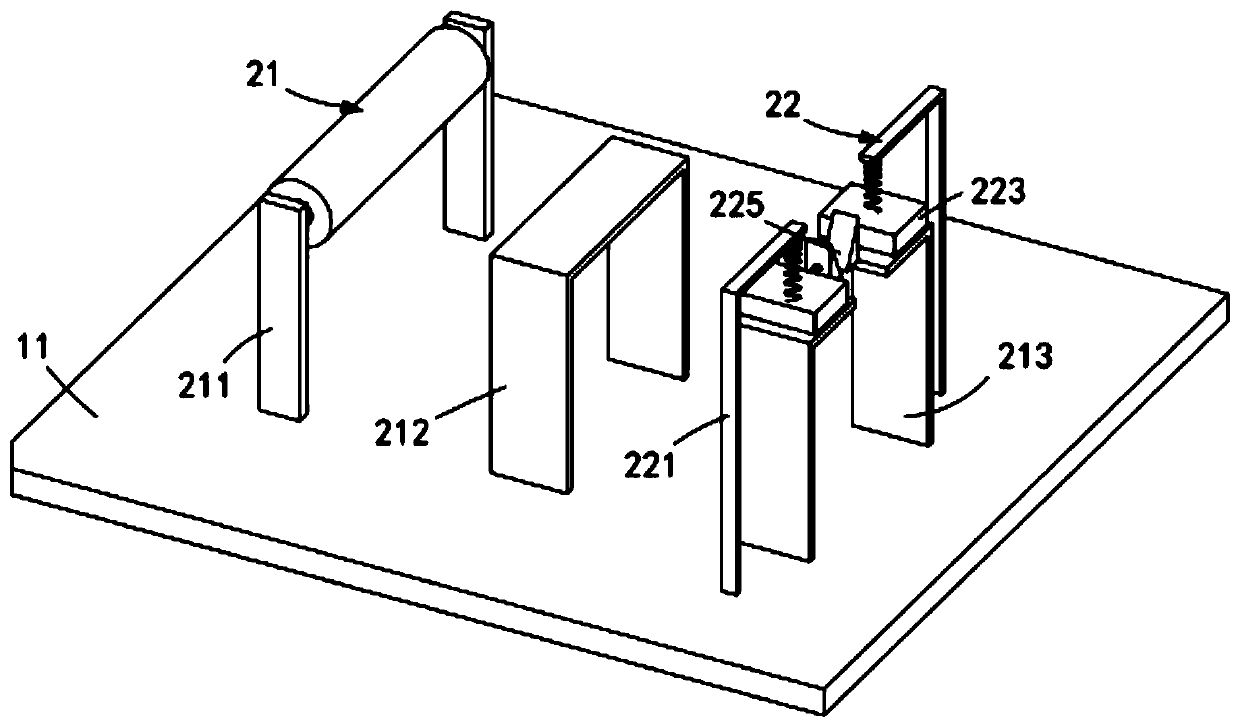

[0064] The film feeding mechanism 2, the film feeding mechanism 2 includes a film feeding assembly 21 arranged on the frame 11 and located on one side of the first drive assembly 12, arranged above the film feeding assembly 21 and connected to the film feeding assembly 21 The limiting assembly 22 of the film pulling assembly 13 intermittent contact and the film releasing assembly 23 arranged on the other side of the first driving assembly 12 relative to the film feeding assembly 21;

[0065] A film pressing mechanism 3, which includes a first film pressing assembly 31 arranged on one side of the film feeding assembly 21 and a second film pressing ...

Embodiment 2

[0110] like Figure 8 , Figure 9 and Figure 10 As shown, the components that are the same as or corresponding to those in the first embodiment are marked with the corresponding reference numerals in the first embodiment. For the sake of simplicity, only the differences from the first embodiment will be described below. The difference between this embodiment two and embodiment one is:

[0111] Further, the second drive assembly 5 includes:

[0112] A pneumatic part 51, the pneumatic part 51 is arranged above the epicyclic mechanism 1 and its telescoping end is arranged vertically downward; and

[0113] The load bearing plate 52 is in transmission connection with the pneumatic component 51 and is arranged horizontally.

[0114] It is worth mentioning here that a sensor is provided on the film release assembly 23. When the film pulling assembly 13 reaches the film release assembly 23, the sensor senses and sends a signal to the second drive assembly 5, and the pneumatic for...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com