Prefabricated finished cable trench

A technology of finished cables and cable trenches, which is applied in the installation of cables and ground cables, etc., which can solve the problems of unfavorable maintenance and maintenance work, complicated operation procedures, and large depth of soil layers, so as to achieve flexible and changeable matching methods and avoid stress Damage, reducing the effect of engineering difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

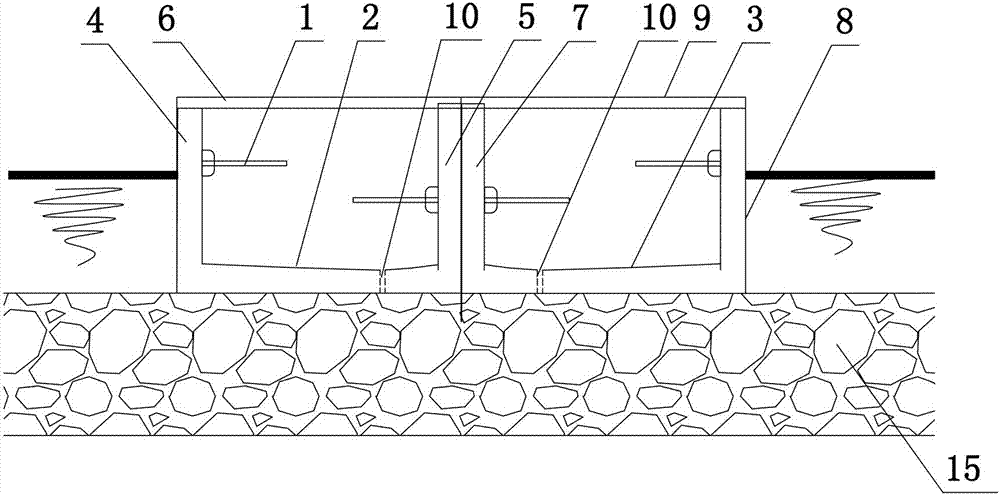

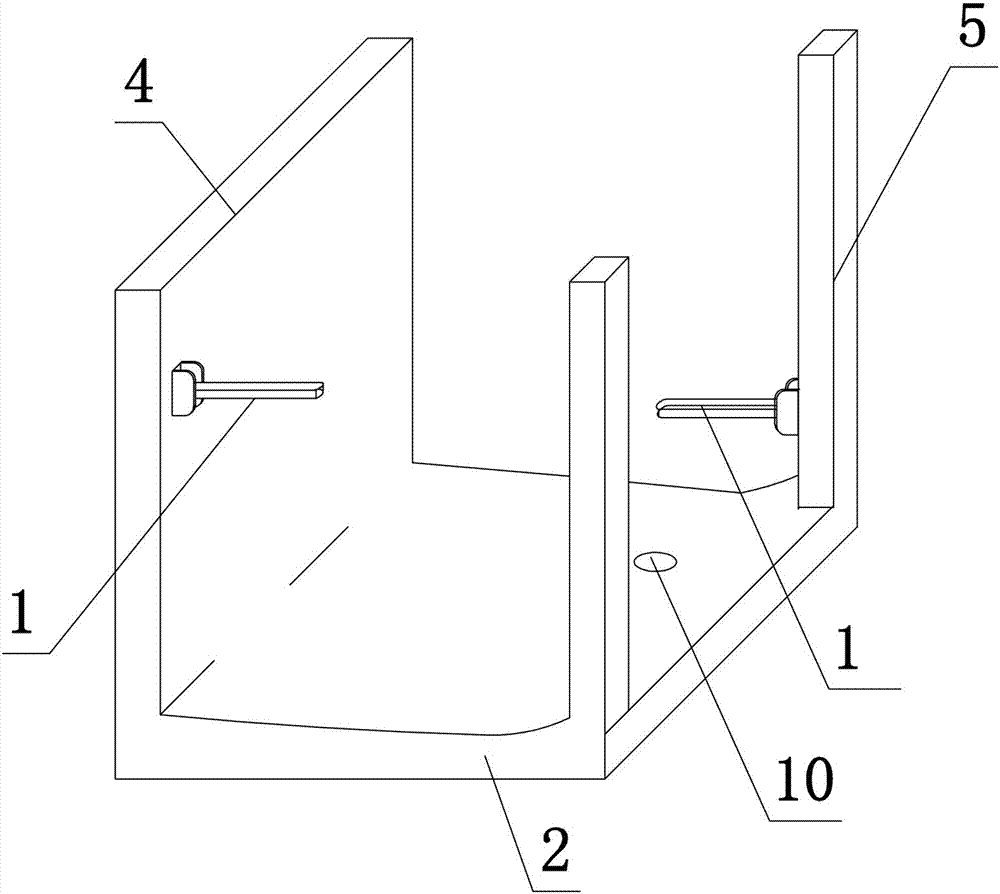

[0039] Such as Figure 1 to Figure 4 As shown, the present invention includes a plurality of cable trench monomers and a crushed stone permeable drainage layer 15 laid below the cable trench, a cable support 1 arranged in the cable trench monomer, and the cable trench monomer includes a prefabricated module fixedly connected to the first trench wall and For the second ditch wall prefabricated module, the gap between the first ditch wall prefabricated module and the second ditch wall prefabricated module is sealed by pouring mortar, and the joints between multiple cable trenches are sealed and fixed by mortar filling;

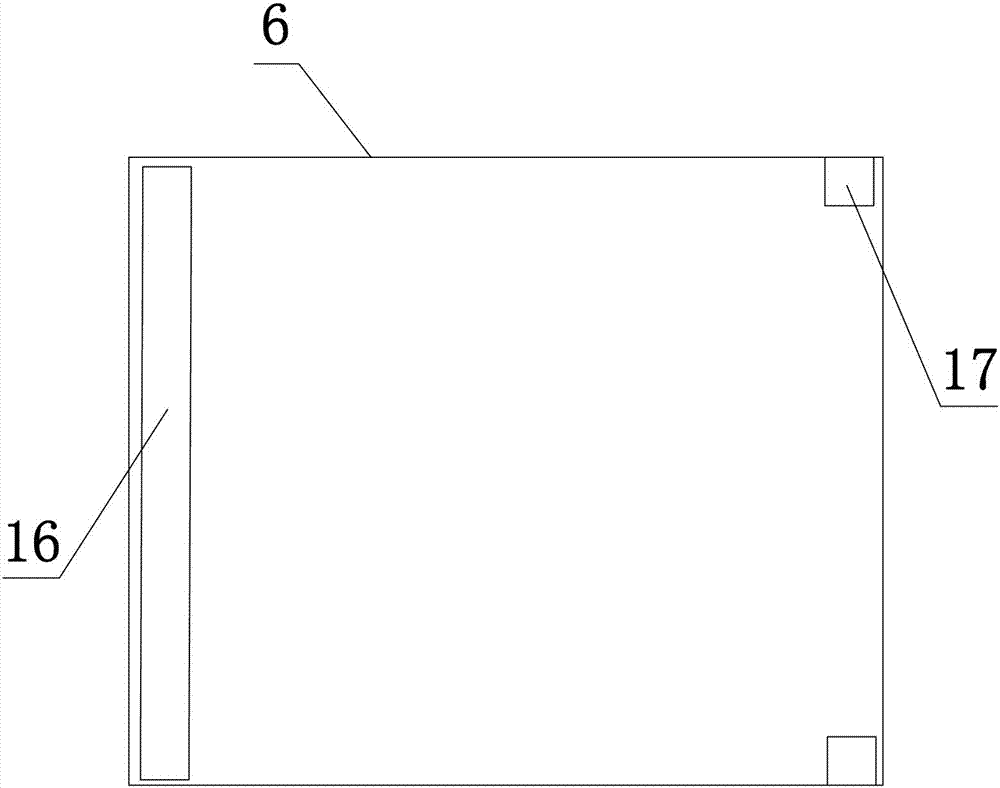

[0040] The first ditch wall prefabricated module includes the first bottom plate 2 and the first ditch wall 4 and the first square steel group 5 integrally formed on the first bottom plate 2. The upper ends of the first ditch wall 4 and the first square steel group 5 are installed with the first A cover plate 6, the lower end surface of the first cover plate 6 i...

Embodiment 2

[0045] The structure of this embodiment is basically the same as that of Embodiment 1, the difference is: as Figure 5 to Figure 7 As shown, one or more intermediate prefabricated modules are added between the first ditch wall prefabricated module and the second ditch wall prefabricated module. The third-party steel group 12 and the fourth-party steel group 13. In this embodiment, a third bottom plate 11 is used as an example for illustration. The third bottom plate 11 is installed between the first bottom plate 2 and the second bottom plate 3 using a reinforced concrete structure. The third-party steel group 12 and the fourth square steel group 13 are pre-buried on the upper end surface of the first bottom plate 11, and the upper ends of the third-party steel group 12 and the fourth square steel group 13 are provided with a third cover plate 14, and the third cover plate 14 The lower end surface is provided with a square groove 17 that engages with the third-party steel group...

Embodiment 3

[0047] The structure of this embodiment is basically the same as that of Embodiment 2, the difference is that: the cable support 1 is provided with an arc-shaped bending portion 18, and the arc of the arc-shaped bending portion 18 is less than 180°; Support rod 19, the other end of support rod 19 is connected with the first ditch wall 4, the second ditch wall 8 or square steel, as Figure 8 As shown, the prefabricated module of the first ditch wall is taken as an example for illustration. In the actual production process, the support rod 19 on the first ditch wall 4 is pre-embedded in the same way as the cable support 1. The first square steel group 5 The upper support rod 19 is fixed by bolts, and the structure of the second ditch wall prefabricated module and the middle module is similar to that of the first ditch wall prefabricated module, which will not be repeated here.

[0048] In the structural design of this embodiment, when in use, the arc-shaped bending part 18 is us...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com