Cold press system

A cold press and object pressing technology, which is applied in the field of cold press systems, can solve problems such as limited space, inconvenient access and movement of forklifts, and affecting the efficiency of loading and unloading of cold presses. compact effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

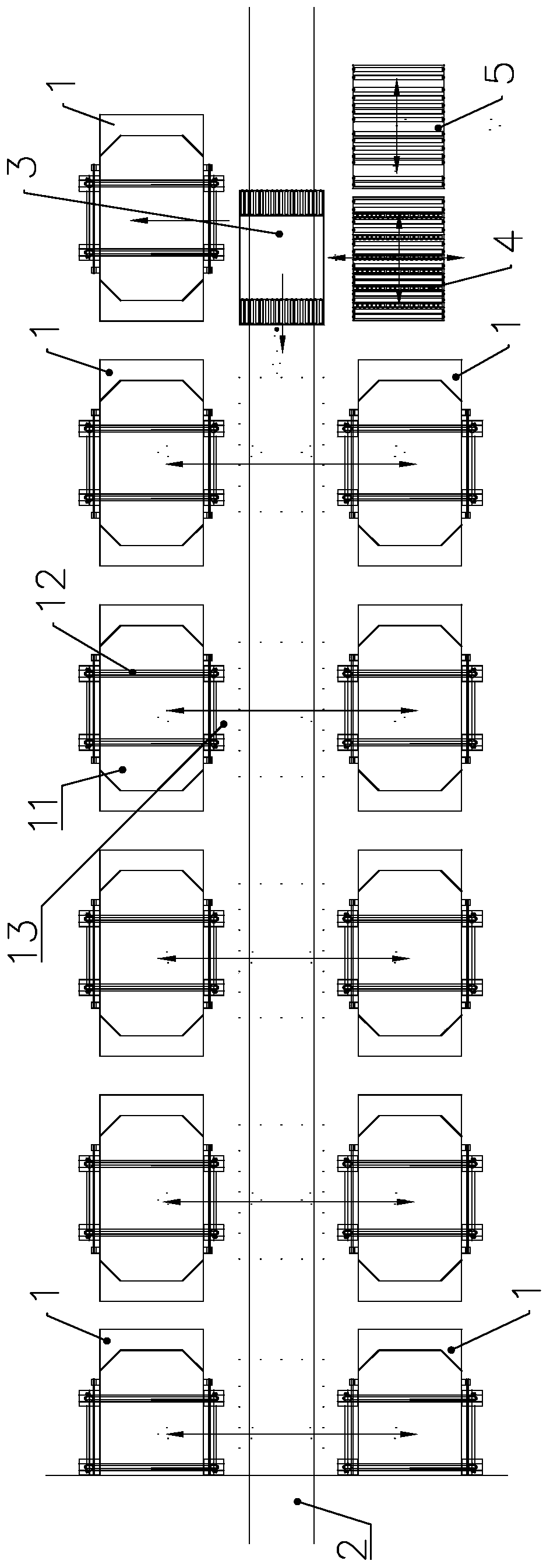

[0031] see figure 1 , the cold press system of the present invention includes a plurality of cold presses 1, a transport track 2 extending from the material sending place to the cold press, and a translation trolley 3 that can slide on the transport track 2 . The cold presses are preferably arranged in pairs on both sides of the transport track 2 . The cold presses in the cold press system have substantially the same structure.

[0032] The cold press system of the present invention also includes a loading and unloading bracket 5 for loading and unloading and a vertical and horizontal conversion bracket 4 for transferring materials from the loading and unloading bracket 5 to the translational trolley 3 .

[0033] Any cold press 1 includes a base 11 and the first conveying device 12 for sending the object to be pressed into the cold press provided on the base; the inlet 13 of any cold press 1 is positive on one side of the transport rail 2.

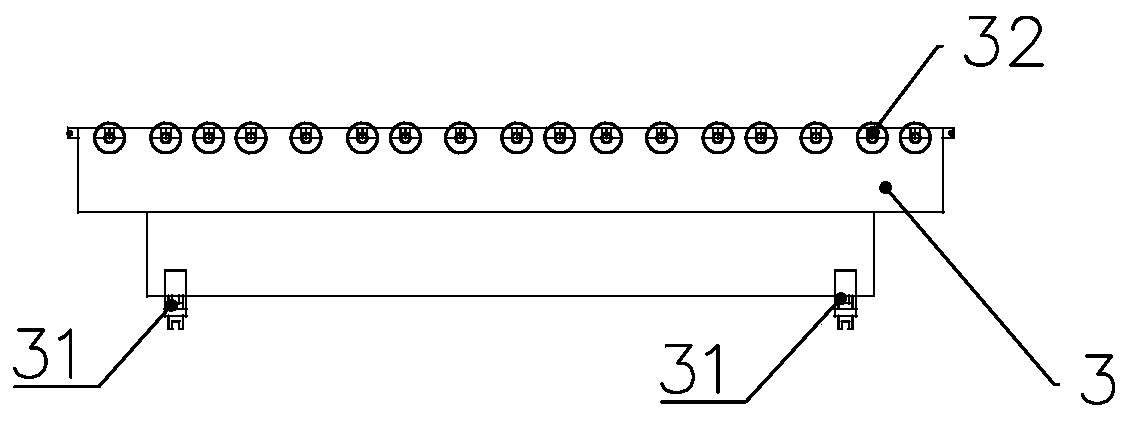

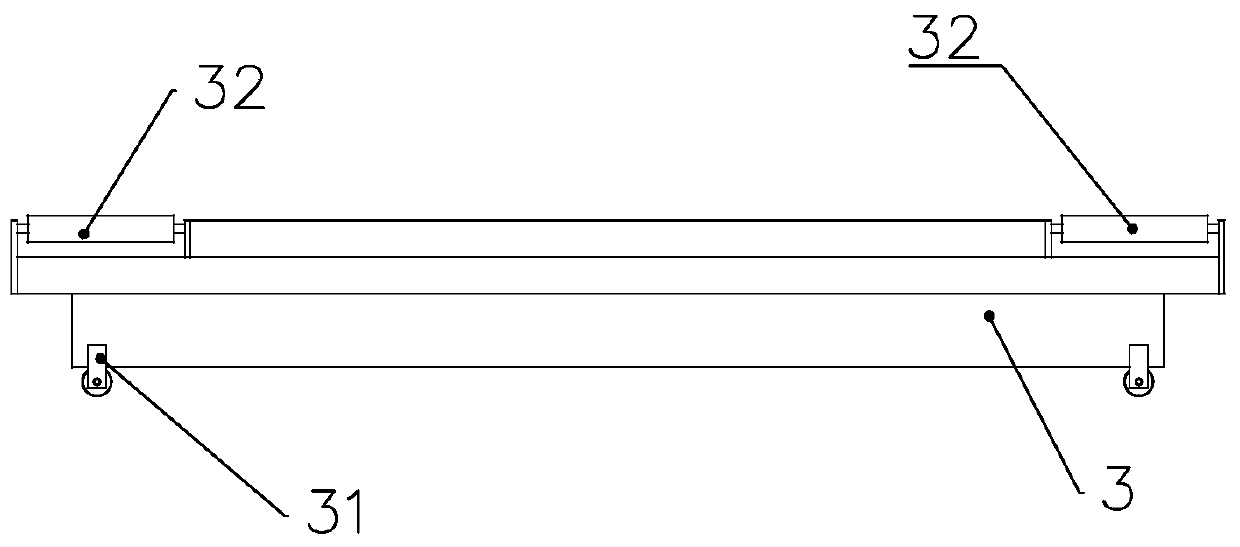

[0034] see Figures 2 to 4 , t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com