Waveguide amplifier

A waveguide amplifier, silicon dioxide technology, used in lasers, laser devices, phonon exciters, etc., can solve the problem of immature erbium-doped waveguide technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

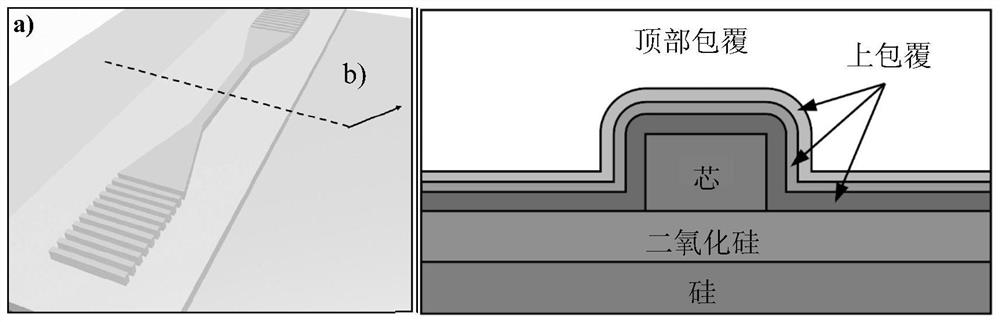

[0072] In this example, a silicon nitride strip waveguide combined with a single Er:Al 2 o 3 Gain layer waveguide amplifier. First, optical-quality silicon dioxide was deposited on the silicon substrate of the device by low-pressure chemical vapor deposition, where the silicon dioxide layer was 1.4 μm thick. Next, a silicon nitride layer with a thickness of 600 nm was deposited on the silicon dioxide layer by plasma enhanced chemical vapor deposition.

[0073]The deposition of the silicon dioxide and silicon nitride layers was followed by deep UV lithography (248nm) and reactive ion etching.

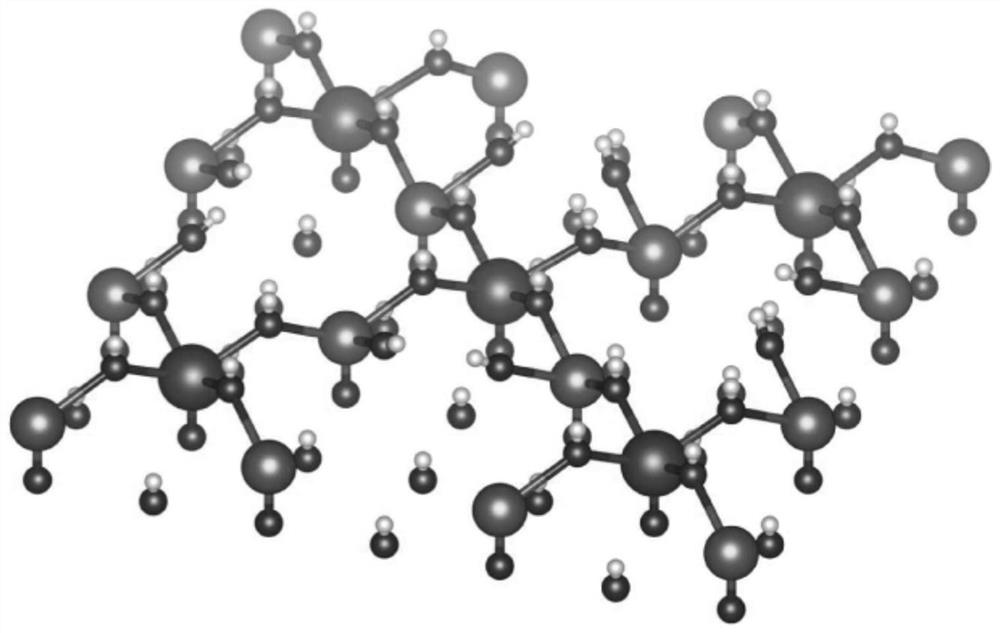

[0074] Erbium oxide (Er 2 o 3 ) and alumina (Al 2 o 3 ) sequentially deposited on the surface of the waveguide channel to use about 150nm thick erbium-alumina (Er:Al 2 o 3 ) layer coating to form the waveguide channel and the whole device. By using Er(thd) 3 Erbium oxide was grown using trimethylaluminum (TMA) and water precursors, while aluminum oxide was grown using trimethyl...

example 2

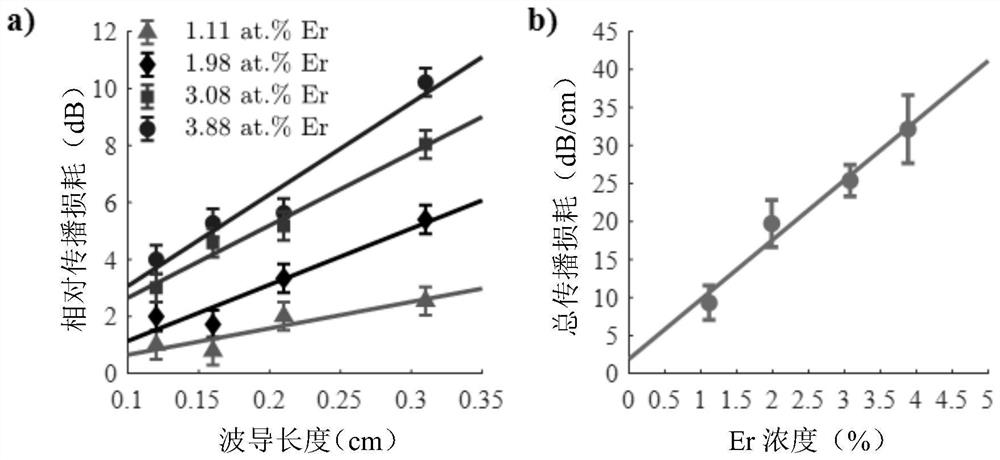

[0087] In this example, an Er:Al 2 o 3 Gain Layer Combination Multilayer Waveguide Amplifier Design. figure 1 b shows a cross-section of the device. Fabricated five different Er:Al on silicon substrates 2 o 3 Gain layers, and their spectral properties were investigated by photoluminescence (PL) characterization. Through numerical simulations, these layers are used to design waveguide amplifiers with improved gain characteristics.

[0088] characterize

[0089] Table 3 shows the cycle sequence and resulting film composition of the erbium-alumina active layer prepared in Example 2.

[0090] Table 3: Characteristics and preparation conditions of the Erbium-Al2O3 active layer deposited by atomic layer deposition

[0091]

[0092] The gain layer was then post-treated at 800° C. for 20 minutes.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com