Outdoor weak current equipment box with heat dissipation function

An electrical equipment, outdoor technology, applied in electrical components, substation/switch layout details, substation/switchgear cooling/ventilation and other directions, can solve the problem of insufficient and uneven heat dissipation, affecting the normal operation of electronic components, etc. Sufficient, high heat dissipation efficiency, and the effect of improving heat dissipation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

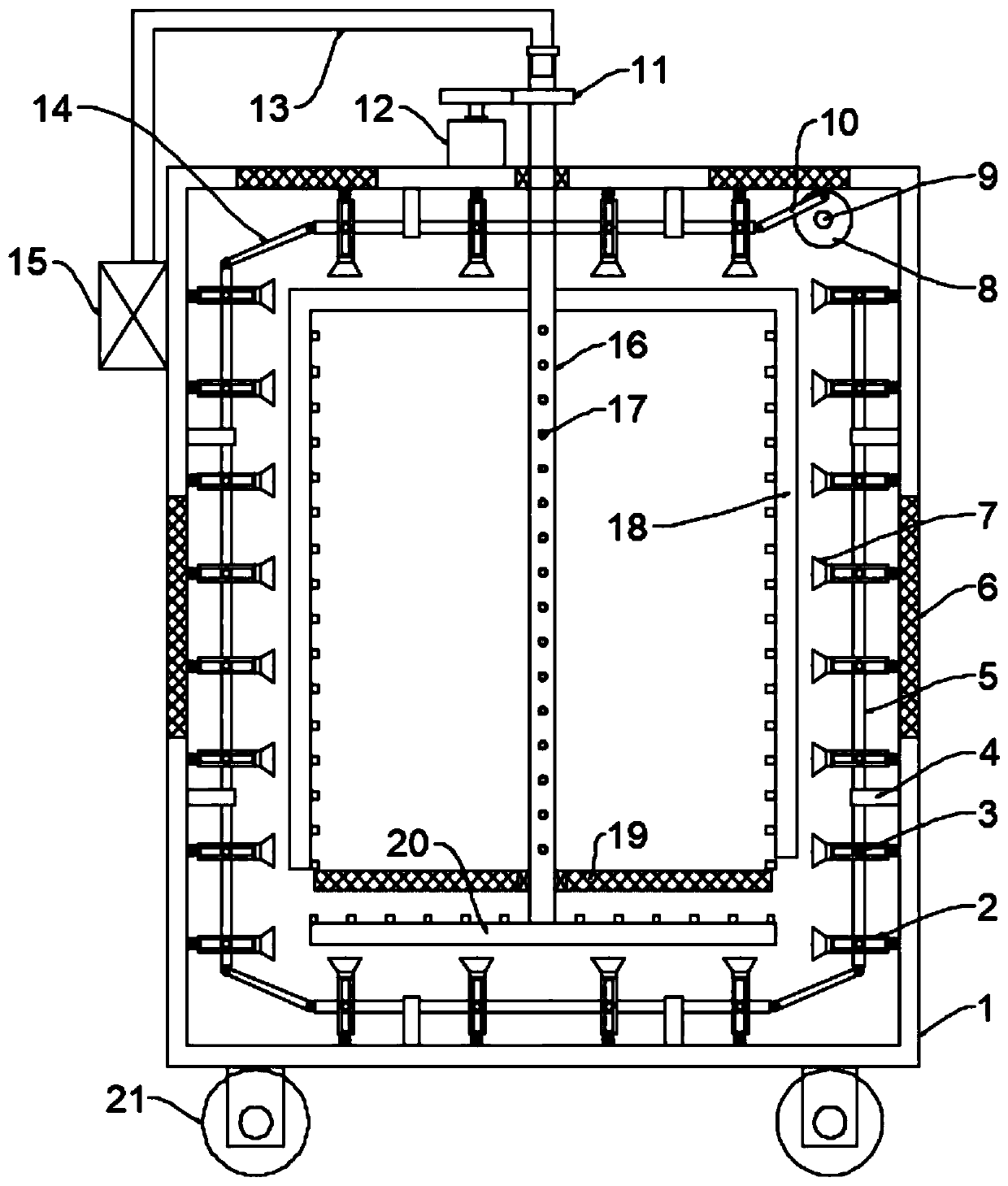

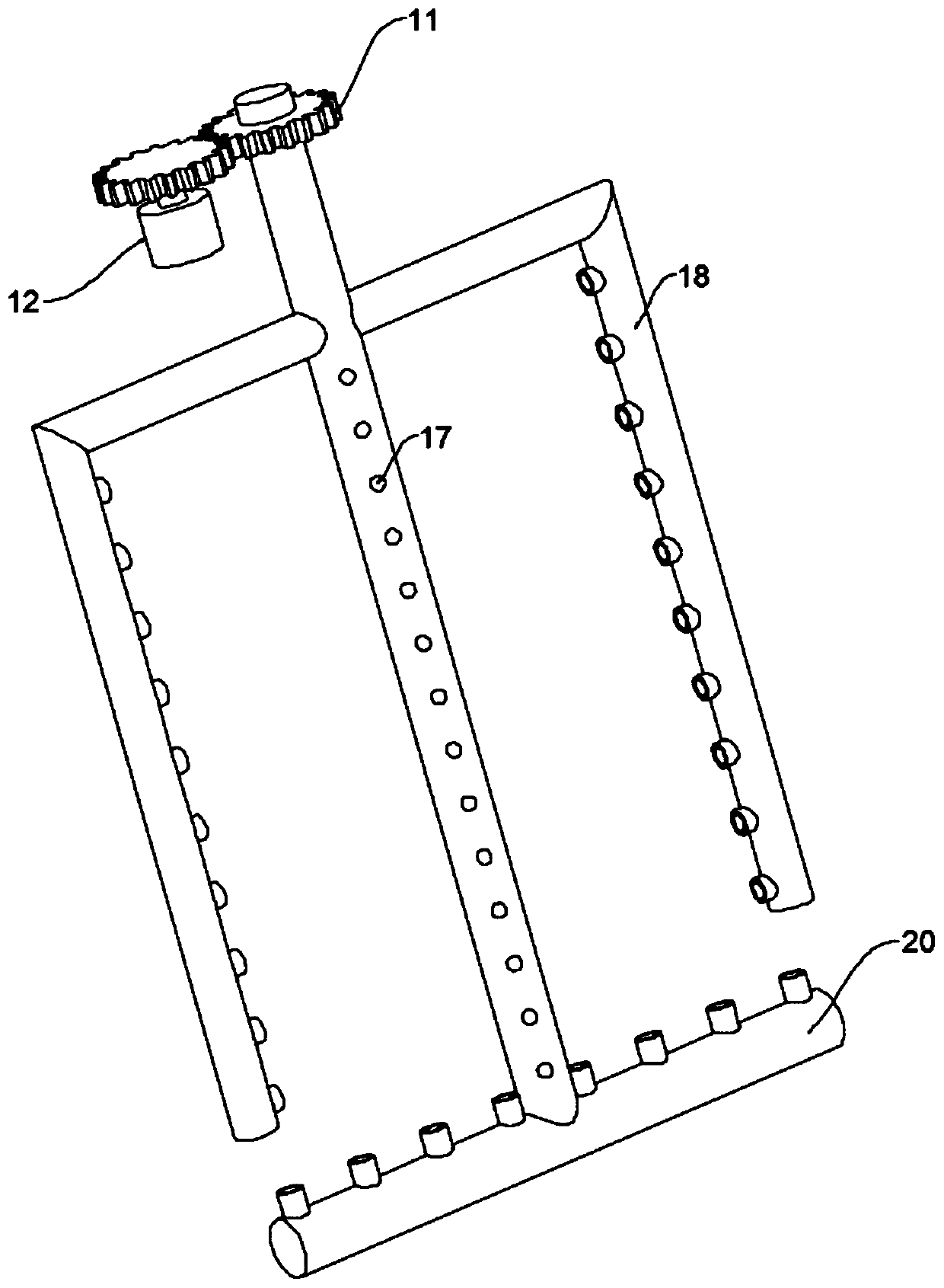

[0024] see Figure 1~2 , in an embodiment of the present invention, an outdoor weak current equipment box with heat dissipation function, including a box body 1, an installation mesh plate 19 for installing electronic components and a heat dissipation unit for cooling electronic components, the bottom of the box body 1 Rollers 21 are evenly and symmetrically fixedly installed, and the rollers 21 are self-locking rollers, which are convenient for the device to move. The box body 1 is equipped with a box door. On the body 1, ventilation nets 6 are installed on the top and side walls of the box body 1, and the heat dissipation unit includes a blowing nozzle 7, a mounting rod 2, a driving rod 5, a first motor 9, a turntable 8, and a first connecting rod 10 and the second connecting rod 14, the inner wall of the box body 1 is hingedly installed with a mounting rod 2 at intervals in the circumferential direction, and the end of the mounting rod 2 away from the inner wall of the box ...

Embodiment 2

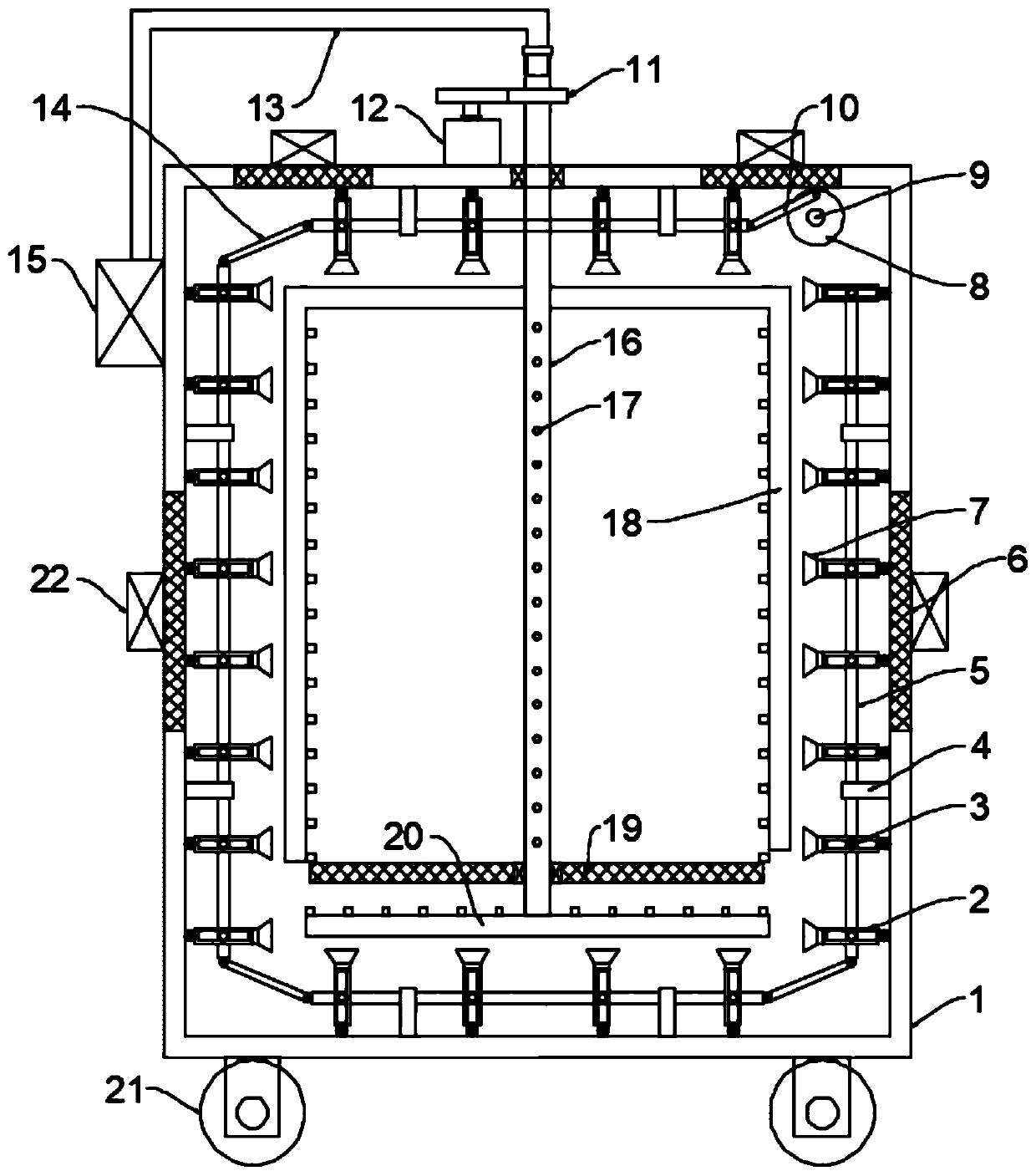

[0027] see image 3 The difference between this embodiment of the present invention and Embodiment 1 is that, further, an exhaust fan 22 is installed on the ventilation net 6 for extracting the hot air in the box body 1 to speed up the circulation of the air.

[0028] The working principle of the present invention is: when working, start the first motor 9, the first motor 9 drives the turntable 8 to rotate, the turntable 8 drives the drive rod 5 connected to it to reciprocate through the first connecting rod 10, and the drive rod 5 passes through the second The connecting rod 14 drives the rest of the driving rod 5 to reciprocate, the driving rod 5 drives the installation rod 2 to swing, and the installation rod 2 drives the blowing nozzle 7 to swing, constantly changing the blowing heat dissipation angle, expanding the heat dissipation range and improving the heat dissipation efficiency, and the heat dissipation fan 15 works , the cooling air enters the hollow rotating shaft ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com