Micro motor with good heat dissipation effect

A micro-motor and cooling effect technology, applied in the direction of electric components, electromechanical devices, electrical components, etc., can solve the problems of motor heat dissipation, high temperature discharge, motor damage, etc., to achieve convenient and rapid heat dissipation, improve service life, efficient and rapid heat dissipation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

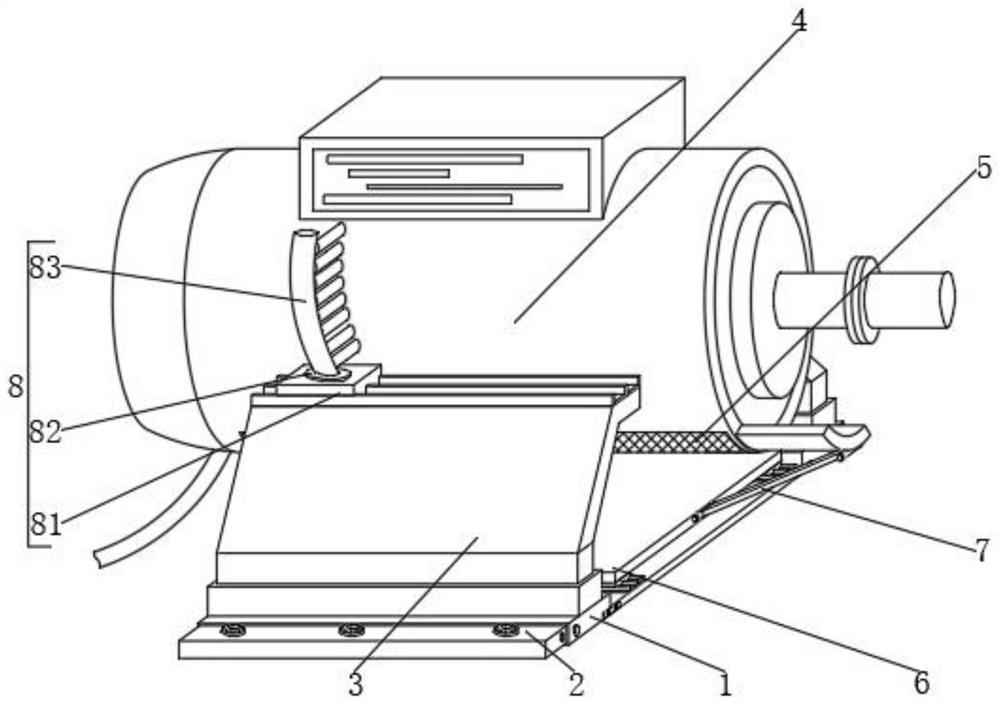

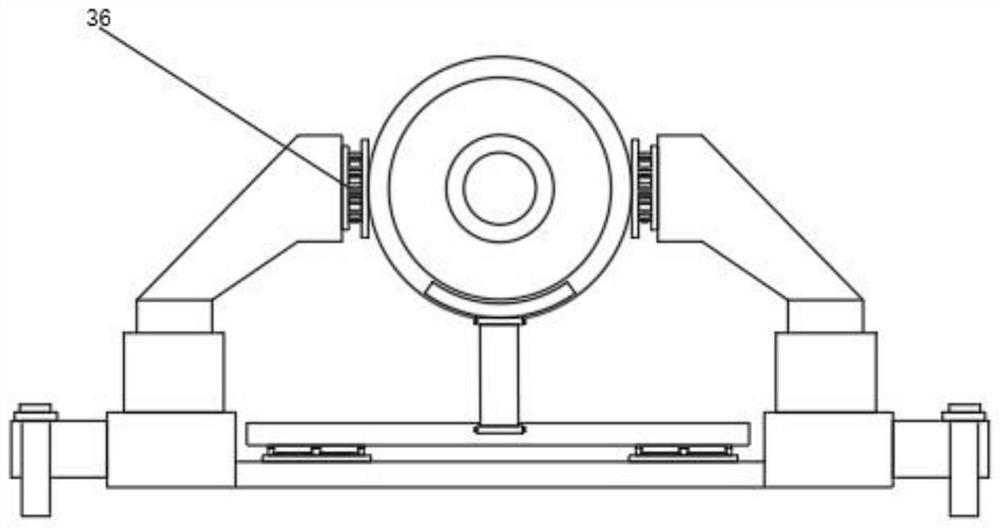

[0032] see Figure 1-7 , In the embodiment of the present invention, a micro motor with good heat dissipation effect includes: a base 1, and also includes an adjusting and fixing mechanism 2, a shock-absorbing support mechanism 3, a heat-dissipating mechanism 6, a linkage mechanism 7 and a cleaning mechanism 8, and an adjusting and fixing mechanism 2 It is arranged on both sides of the inner wall of the base 1, the shock absorption support mechanism 3 is fixedly installed on the top of the shock absorption support mechanism 3, the motor 4 is fixedly installed on the inner side of the shock absorption support mechanism 3, the bottom opening and closing mechanism 5 is arranged on one side of the motor 4, and the heat dissipation mechanism 6 is installed. It is fixedly installed on the inner side of the base 1; the heat dissipation mechanism 6 includes two connecting blocks 61 fixedly installed on both sides of the base 1, a mounting plate 62 fixedly installed between the two conn...

Embodiment 2

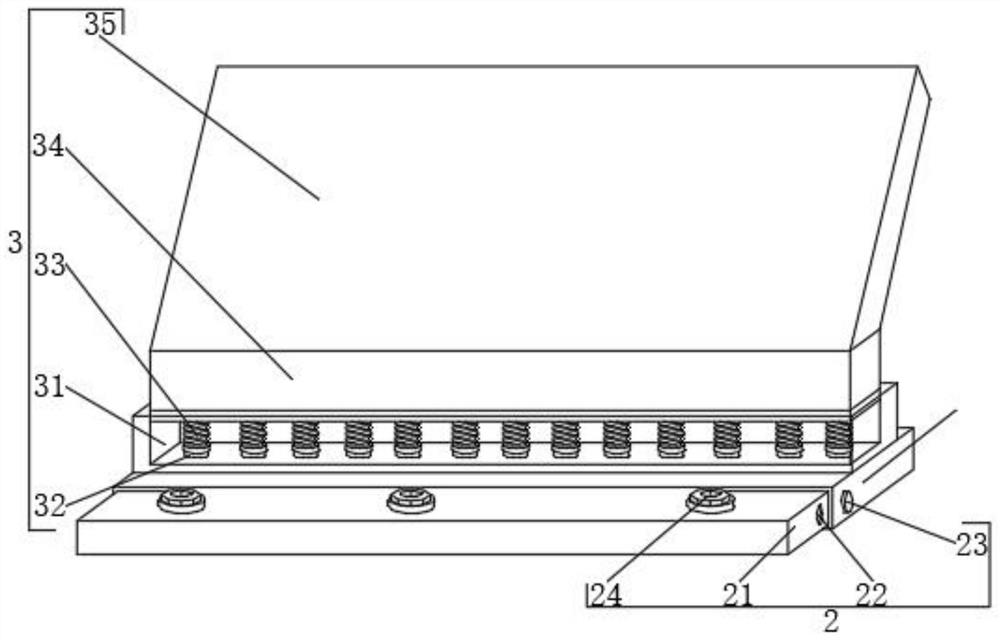

[0034] see figure 1 and Figure 7 , and the difference from Embodiment 1 is: a micro-motor with good heat dissipation effect, comprising: the shock-absorbing support mechanism 3 includes two telescopic sleeves 31 fixedly installed on both sides of the top of the base 1, and a plurality of telescopic sleeves 31 fixedly installed on the two Each of the fixing blocks 32 inside the telescopic sleeves 31 , the two telescopic plates 34 fitted on the inner sides of the two telescopic sleeves 31 , and the two support frames 35 fixedly installed on the tops of the two telescopic plates 34 , respectively. A telescopic spring 33 is connected between the telescopic plates 34, which can buffer and damp the motor 4 more conveniently, and prevent the motor 4 from shaking greatly during the use of the motor 4, resulting in loose or damaged internal parts, affecting the subsequent usage of.

[0035] The working principle of the present invention is: firstly pull the extension block 21 to pul...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com