Manufacturing process for surface replacement femoral head and femoral head

A manufacturing process and femoral head technology, applied in the medical field, can solve the problems of increasing the economic burden of patients, inability to carry out integral forging, and low service life, and achieve better self-locking effect, avoid loosening, and increase friction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment 1

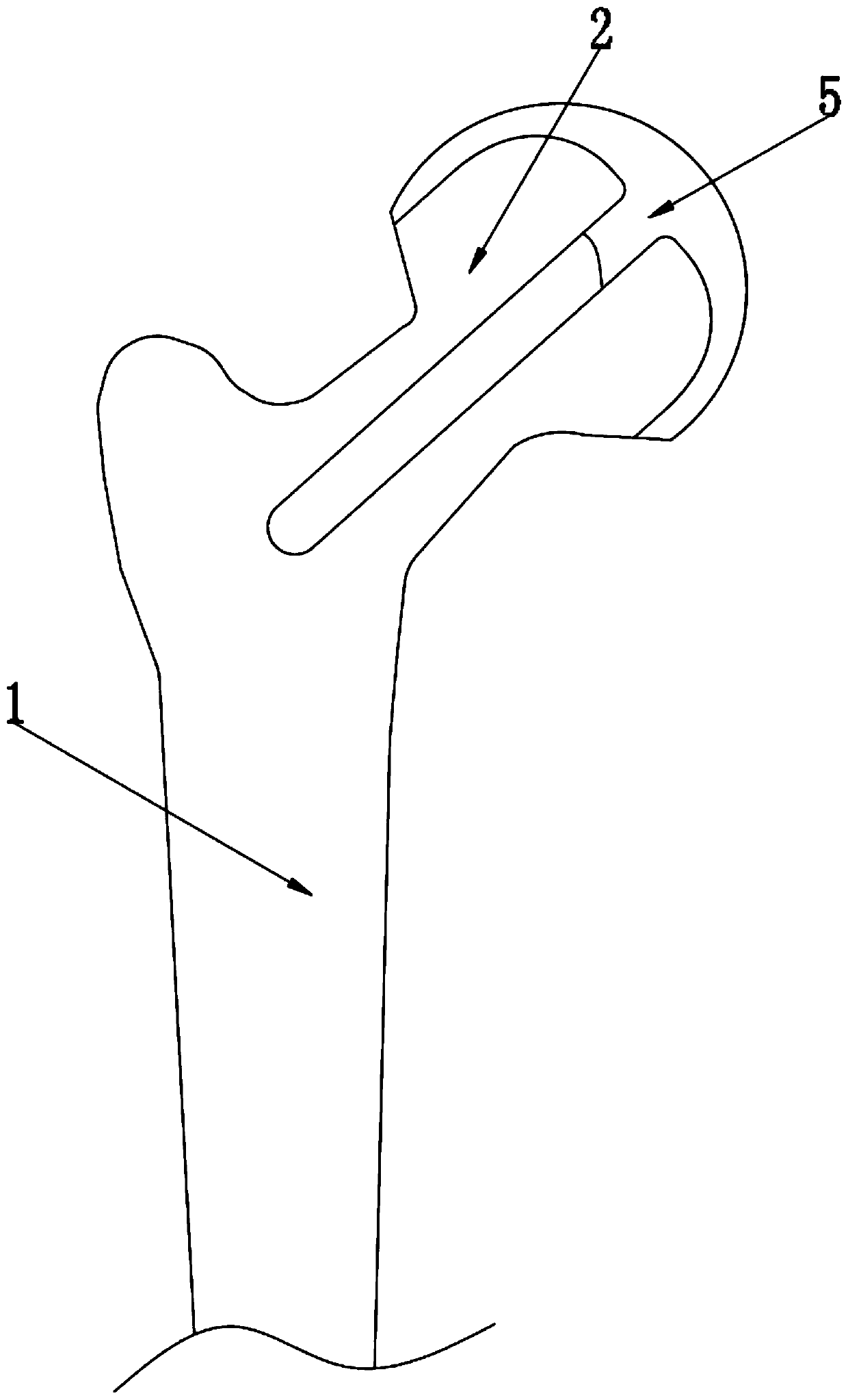

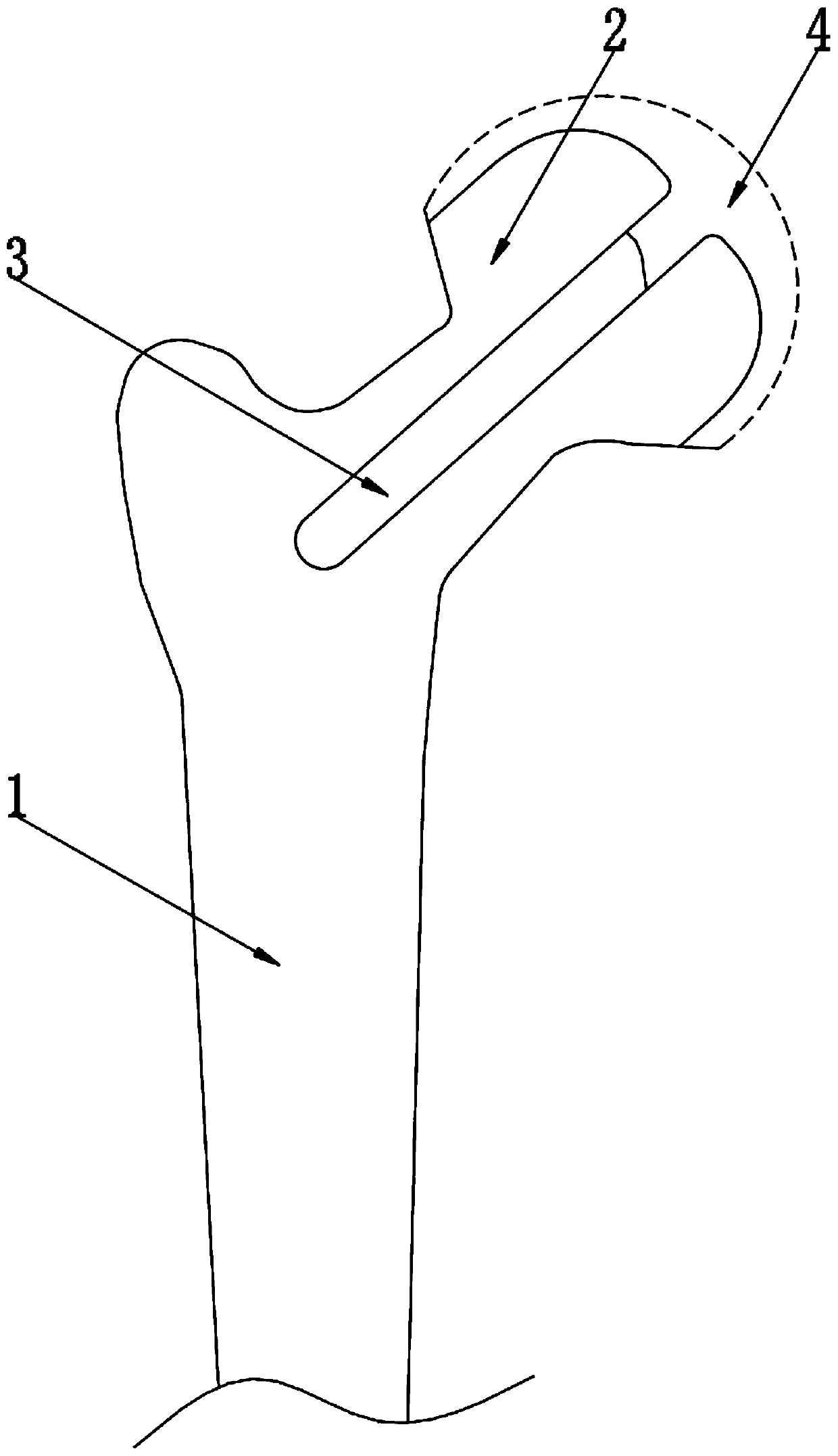

[0049] Embodiment one: a kind of manufacturing process of surface replacement femoral head, this manufacturing process comprises the following steps:

[0050] S1. Manufacture and produce the replacement femoral head surface;

[0051] S2. Turning the replacement femoral head surface;

[0052] S3, frosting the self-locking surface and the self-locking cone;

[0053] S4, carry out secondary turning processing to fixed thread groove;

[0054] S5, grinding the replacement femoral head surface;

[0055] S6, polishing the replacement surface.

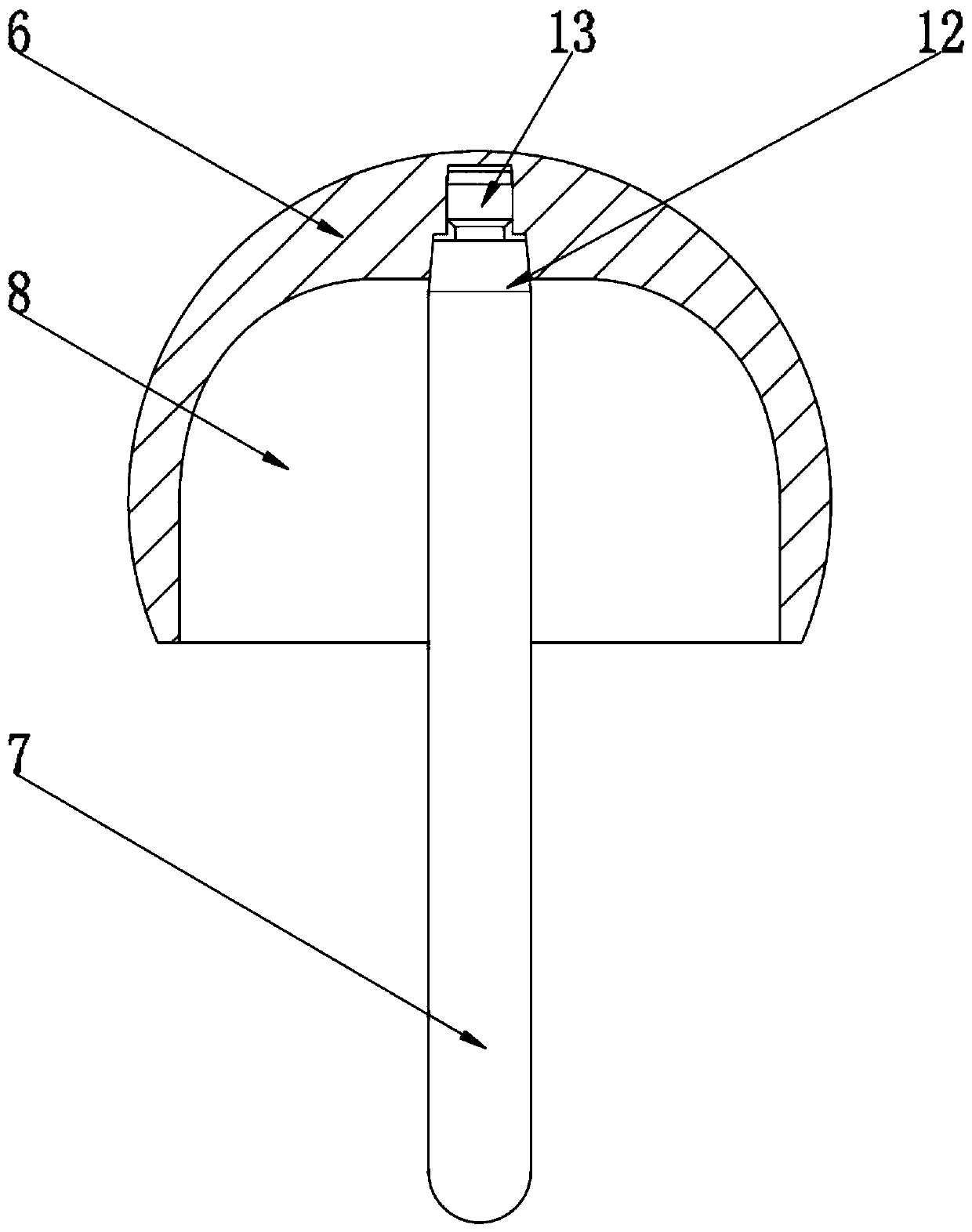

[0056] In the step S1, the replacement surface 6 is forged with a cobalt-chromium-molybdenum alloy, the insertion rod 7 is forged or cast with a cobalt-chromium-molybdenum alloy, and the replacement surface 6 after production is heat treated to eliminate forging stress and improve The machinability of cobalt-chromium-molybdenum alloys, the temperature of the heat treatment is 1320 ° C, after the heat treatment, nitrogen gas is introduced a...

Embodiment 2

[0069] Embodiment two: a kind of manufacturing process of surface replacement femoral head, this manufacturing process comprises the following steps:

[0070] S1. Manufacture and produce the replacement femoral head surface;

[0071] S2. Turning the replacement femoral head surface;

[0072] S3, frosting the self-locking surface and the self-locking cone;

[0073] S4, carry out secondary turning processing to fixed thread groove;

[0074] S5, grinding the replacement femoral head surface;

[0075] S6, polishing the replacement surface.

[0076] In the step S1, the replacement surface 6 is forged with a cobalt-chromium-molybdenum alloy, the insertion rod 7 is forged or cast with a cobalt-chromium-molybdenum alloy, and the replacement surface 6 after production is heat treated to eliminate forging stress and improve The machinability of cobalt-chromium-molybdenum alloys, the temperature of the heat treatment is 1340 ° C, after the heat treatment, nitrogen gas is introduced a...

Embodiment 3

[0089] Embodiment three: a kind of manufacturing process of surface replacement femoral head, this manufacturing process comprises the following steps:

[0090] S1. Manufacture and produce the replacement femoral head surface;

[0091] S2. Turning the replacement femoral head surface;

[0092] S3, frosting the self-locking surface and the self-locking cone;

[0093] S4, carry out secondary turning processing to fixed thread groove;

[0094] S5, grinding the replacement femoral head surface;

[0095] S6, polishing the replacement surface.

[0096] In the step S1, the replacement surface 6 is forged with a cobalt-chromium-molybdenum alloy, the insertion rod 7 is forged or cast with a cobalt-chromium-molybdenum alloy, and the replacement surface 6 after production is heat treated to eliminate forging stress and improve The machinability of cobalt-chromium-molybdenum alloys, the temperature of the heat treatment is 1360 ° C, after the heat treatment, nitrogen gas is introduced...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com