Bulkhead air-purifying respirator

A respirator and filter technology, which is applied in the field of filter respirators, can solve the problems of inability to adjust the accuracy of the filter, inconvenient replacement of the filter body, and affect the working efficiency, so as to achieve fast and convenient installation and disassembly, and reduce the filtration rate. Burden, the effect of improving the filtering effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The content of the present invention will be further described in detail below in conjunction with the accompanying drawings.

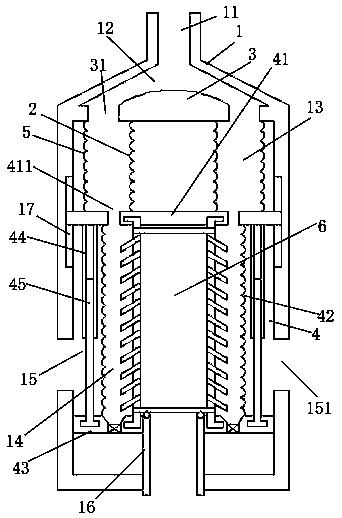

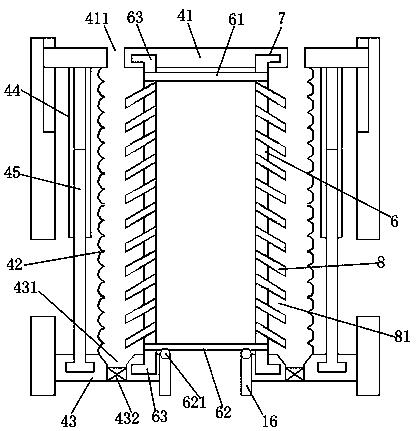

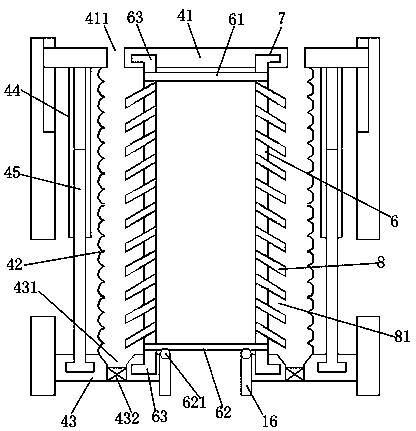

[0021] Such as Figures 1 to 2 As shown, a filter respirator with partitions includes a housing 1, a closed telescopic tube 2, an elastic filter screen 6, an adjustment assembly 4, a partition plate 3, and a partition ring plate 8; the upper end of the casing 1 An air inlet pipe 11 is provided; the inside of the housing 1 is provided with a filter chamber; the partition plate 3 is installed on the upper end of the housing 1; the upper end of the partition board 3 is provided with an air inlet chamber 12; The upper annular vent 31 is provided around the partition plate 3; the adjustment assembly 4 includes a sliding plate 41, a guide thread cylinder 44, a guide thread column 45, a positioning plate 43, and a lower sealing telescopic tube 42; The sliding plate 41 and the positioning plate 43 are installed up and down inside the housing 1 respect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com