Lifting scraper device capable of automatically clearing material sticking to scraper edge

A scraper device and automatic cleaning technology, applied in cleaning methods and utensils, cleaning methods using tools, chemical instruments and methods, etc., can solve problems such as trouble, not tight fitting of the scraper, easy adhesion behind the scraper, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

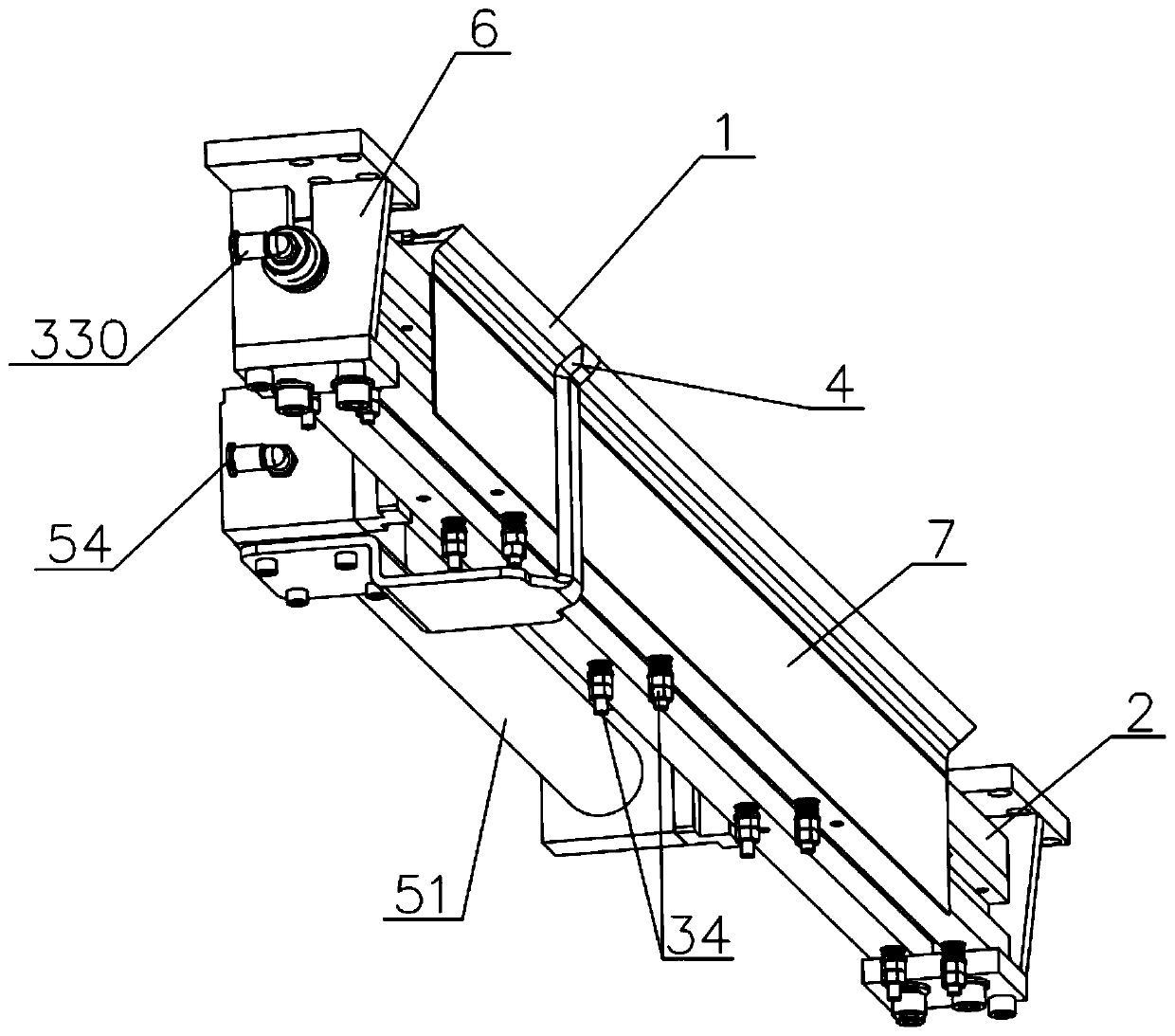

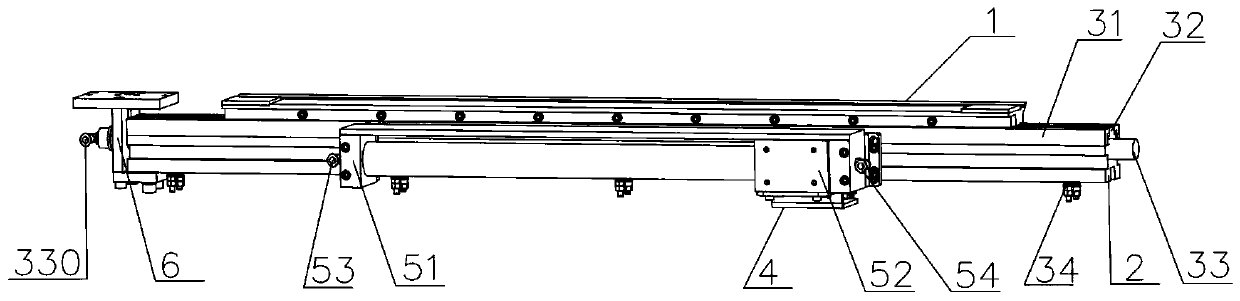

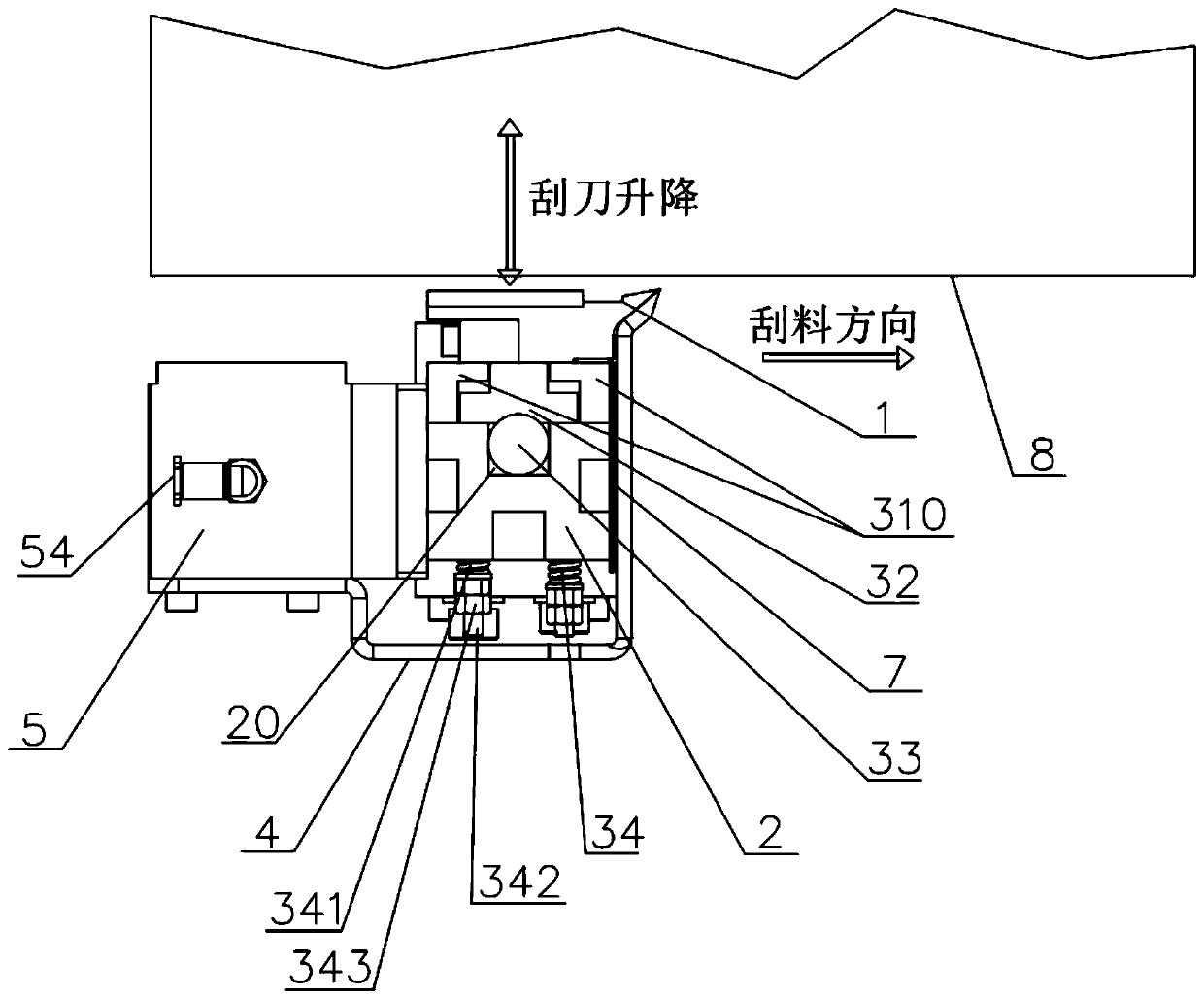

[0017] Such as Figure 1 to Figure 3 As shown, a lifting scraper device that can automatically clean the sticky material on the cutting edge includes a scraper 1 for cleaning the muddy composite material on the working surface 8, a scraper seat 2 for installing the scraper 1, and a scraper 1 for lifting The air bag lifting assembly, the scraper 4 for cleaning the sticky material on the edge of the scraper 1, the sliding assembly for pushing the scraper 4 to reciprocate, and the mounting bracket 6 for connecting the peripheral drive device, the scraper 1 is located on the top of the airbag lifting assembly, the sliding assembly is located on the side of the scraper seat 2, the scraper 4 half surrounds the scraper seat 2, one end of the scraper 4 is connected to the bottom of the sliding assembly, the scraper 4 The other end is a blade, the bl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com