Hot metal ladle

A ladle and iron slag technology, applied in the direction of casting melt containers, metal processing equipment, casting equipment, etc., to achieve the effect of good product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

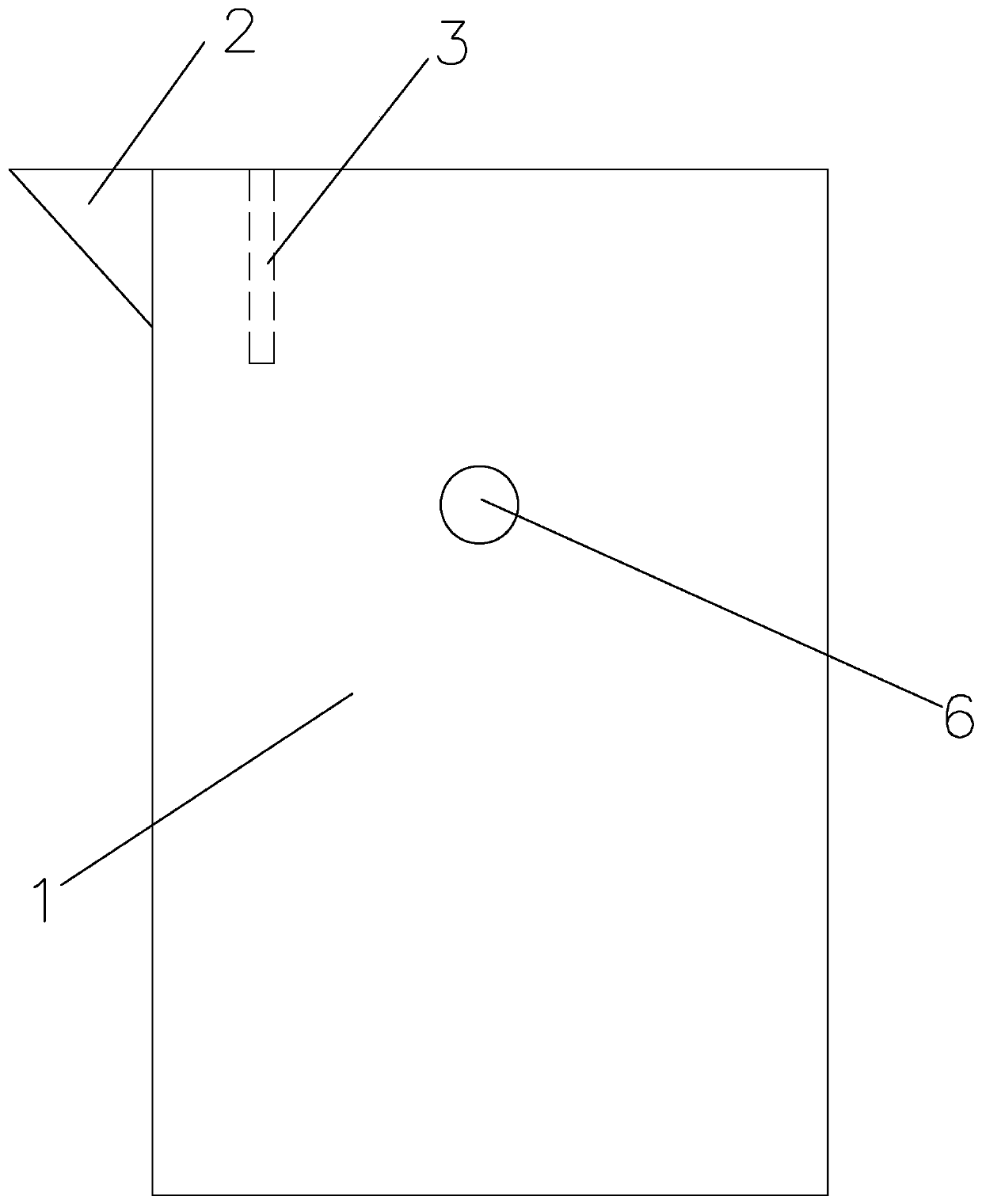

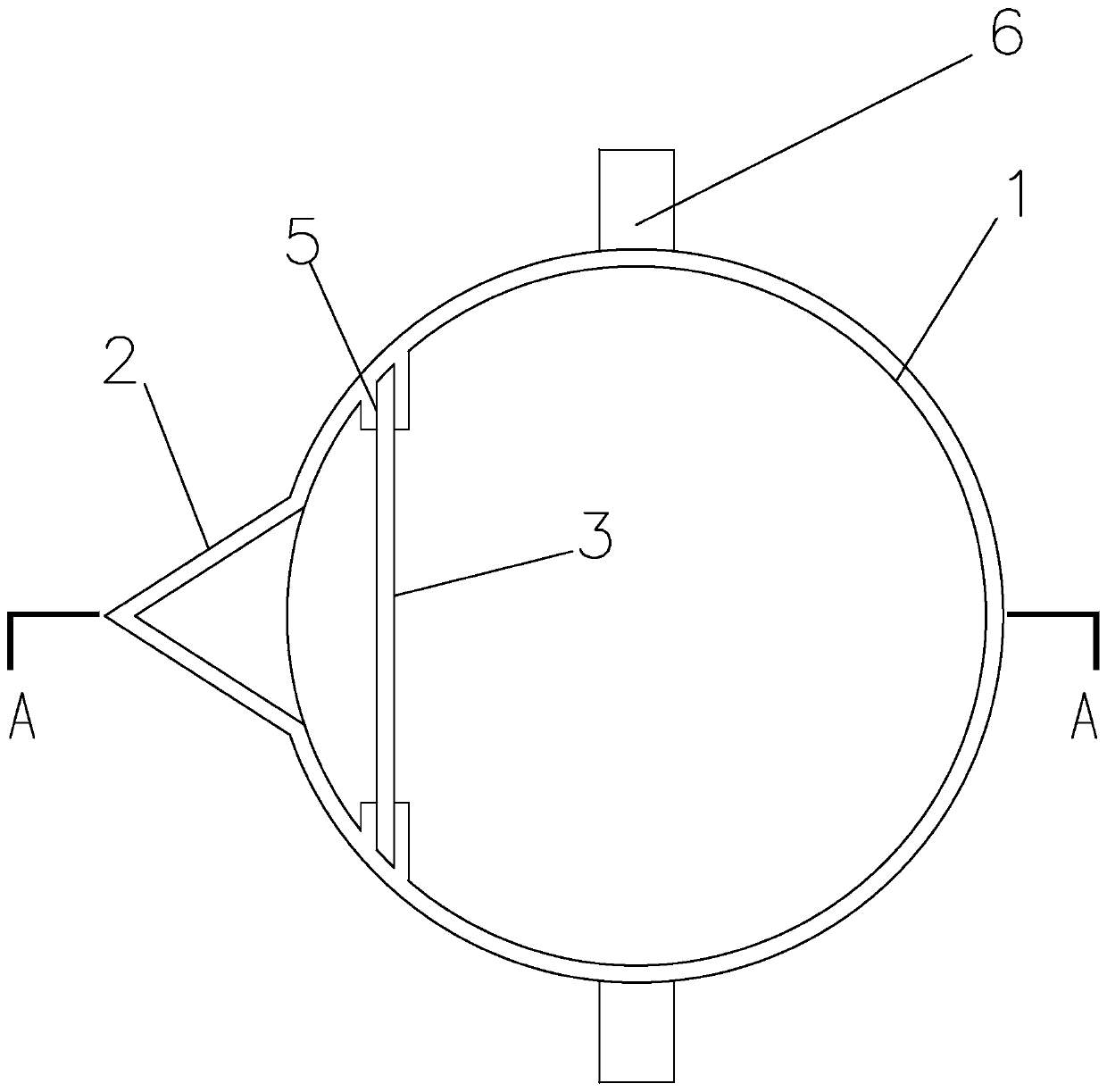

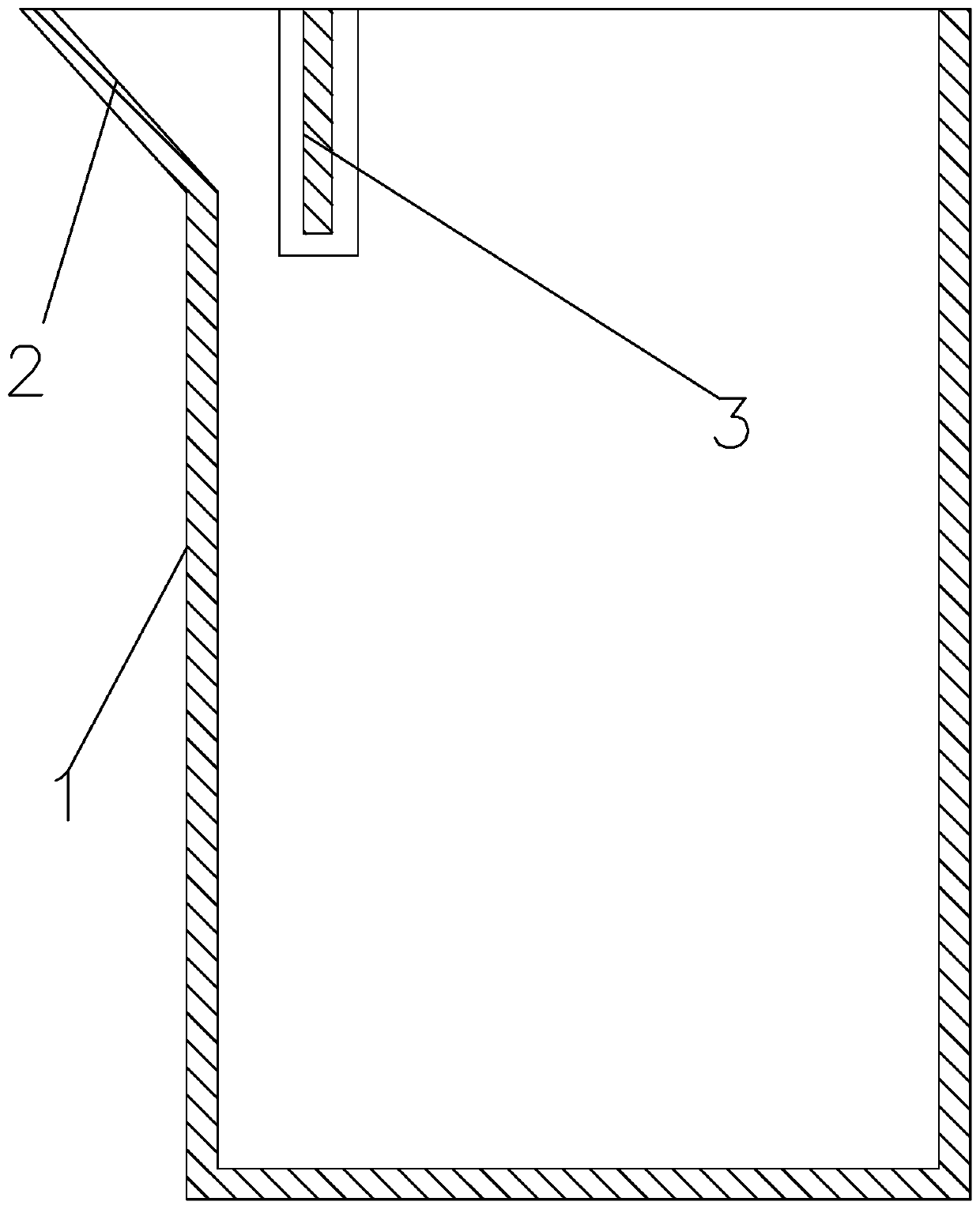

[0025] see Figure 1 to Figure 8 , a ladle, comprising a barrel 1, a mouth 2 located at the mouth of the barrel 1, and a rotating shaft 6 outside the barrel 1, wherein the barrel 1 is provided near the mouth 2 There is a slag retaining plate 3 for blocking iron slag 24 when pouring molten iron 4, the inner side wall of the barrel part 1 is provided with a slot 5 adapted to the slag retaining plate 3 at a position corresponding to the slag retaining plate 3, and the slag retaining plate 3 The edges on opposite sides are located in the slot 5; the height of the bottom of the slag retaining plate 3 is lower than that of the bottom of the mouth 2; a base 8 is provided under the barrel 1, and a bracket 9 is fixedly connected to the base 8 , the barrel part 1 is a cylindrical structure, the outer side of the barrel part 1 is covered with a coaxial rotating ring 7, the rotating ring 7 is connected to the barrel part 1 in rotation, and the outer side of the barrel part 1 is provided o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com