An ultra-precise flexible rotor double-sided on-line deweighting dynamic balancing system

A flexible rotor and balance system technology, applied in metal processing equipment, welding equipment, manufacturing tools, etc., can solve problems affecting production efficiency, high precision, and inability to guarantee, so as to save production consumption costs, improve balance efficiency, and save labor cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

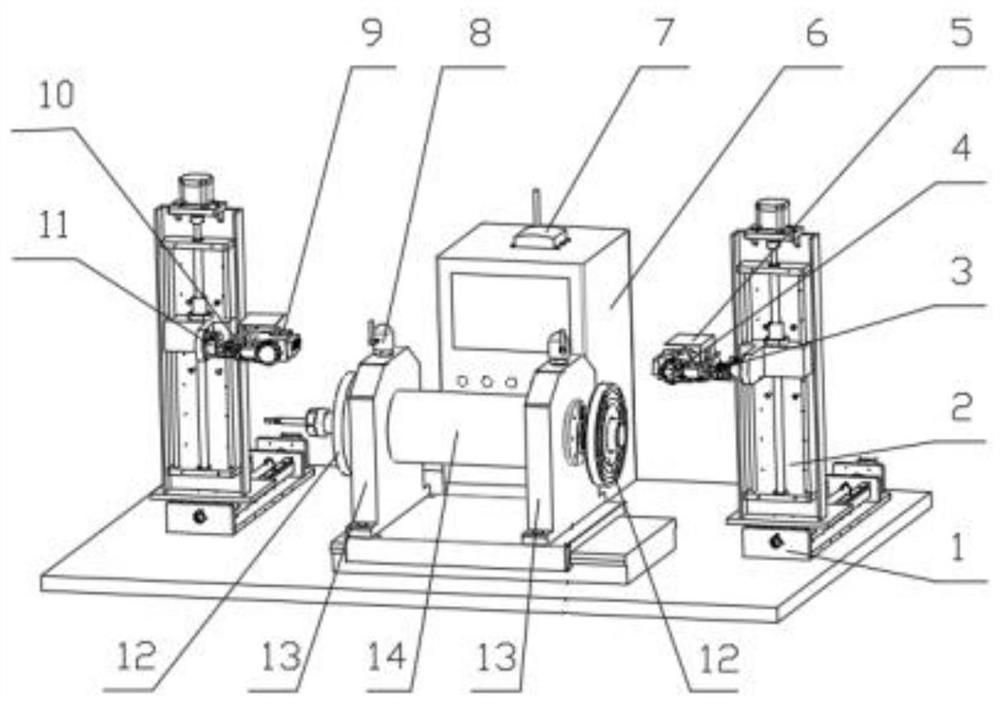

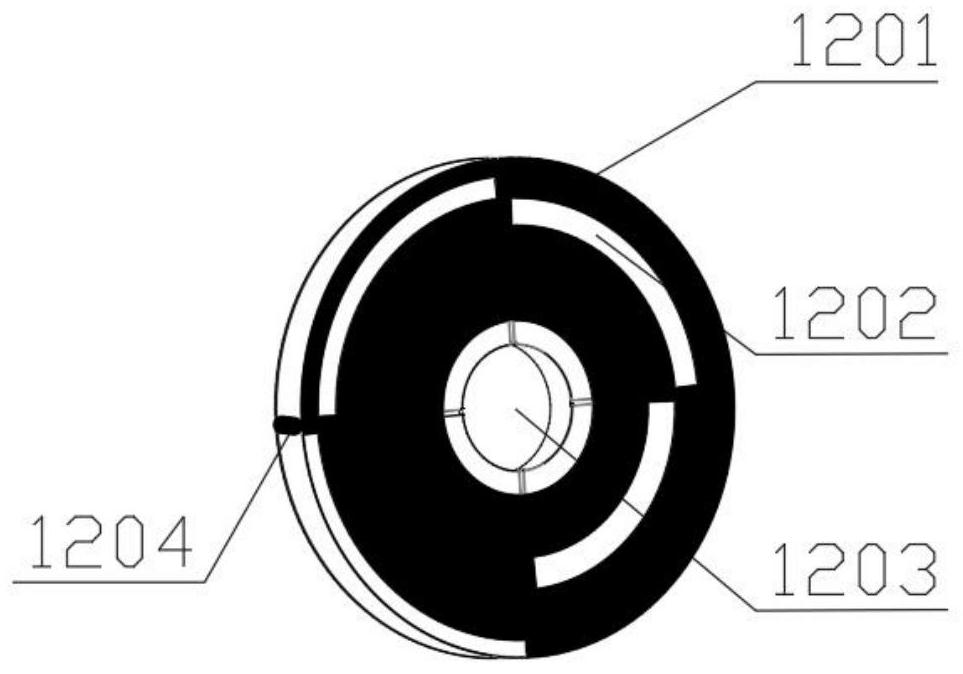

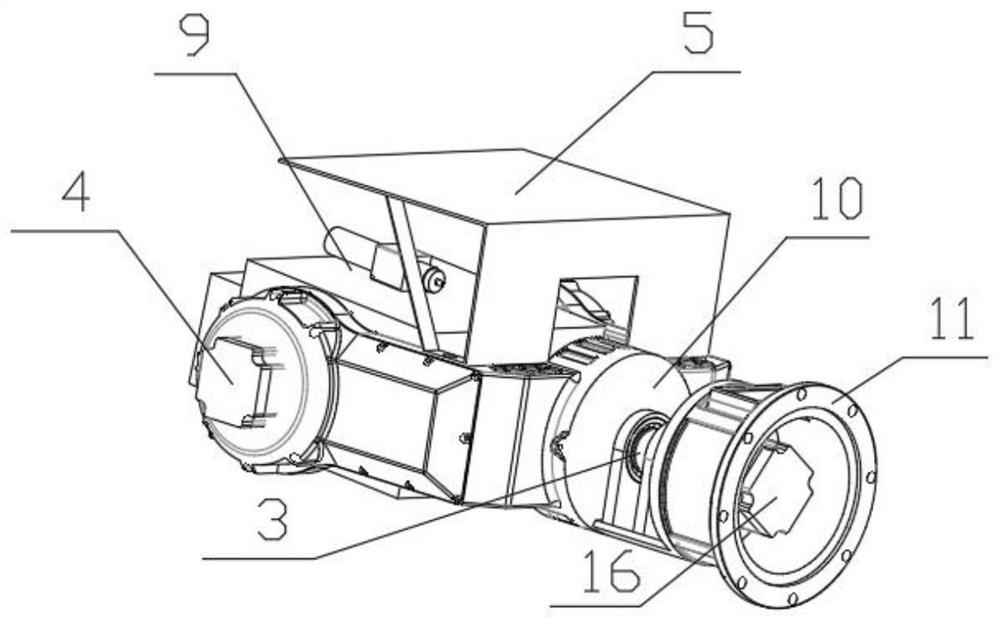

[0020] refer to figure 1 , figure 2 , image 3 and Figure 4 , an ultra-precision flexible rotor double-sided on-line weight-removing dynamic balancing system, including an ultra-high-speed flexible spindle 14, the ultra-high-speed flexible spindle 14 is supported on a spindle fixture 13, and unbalanced weight-removing discs are installed at both ends of the ultra-high-speed flexible spindle 14 12. Under the high-speed rotation of the ultra-high-speed flexible spindle 14, the laser can accurately remove the materials in the different phase de-emphasis areas 1202 of the unbalanced de-weighting disc 12 to realize the quality adjustment of the entire spindle system, and complete the unbalanced quality compensation. Unbalanced de-weighting disc 12 is used as the weight removal object, avoiding the weight removal directly on the ultra-high-speed flexible spindle 14; each unbalanced weight removal disc 12 is equipped with a laser online weight removal system, and two laser online...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com