Fully-automatic welding device for spiral bin

A fully automatic welding and spiral warehouse technology, applied in other manufacturing equipment/tools, manufacturing tools, etc., can solve the problems of high precision adjustment of workers' technical equipment, heavy welding work, poor sealing, etc., to avoid major safety accidents. Occurrence, time-saving and labor-saving work efficiency, the effect of neat and consistent welding position

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

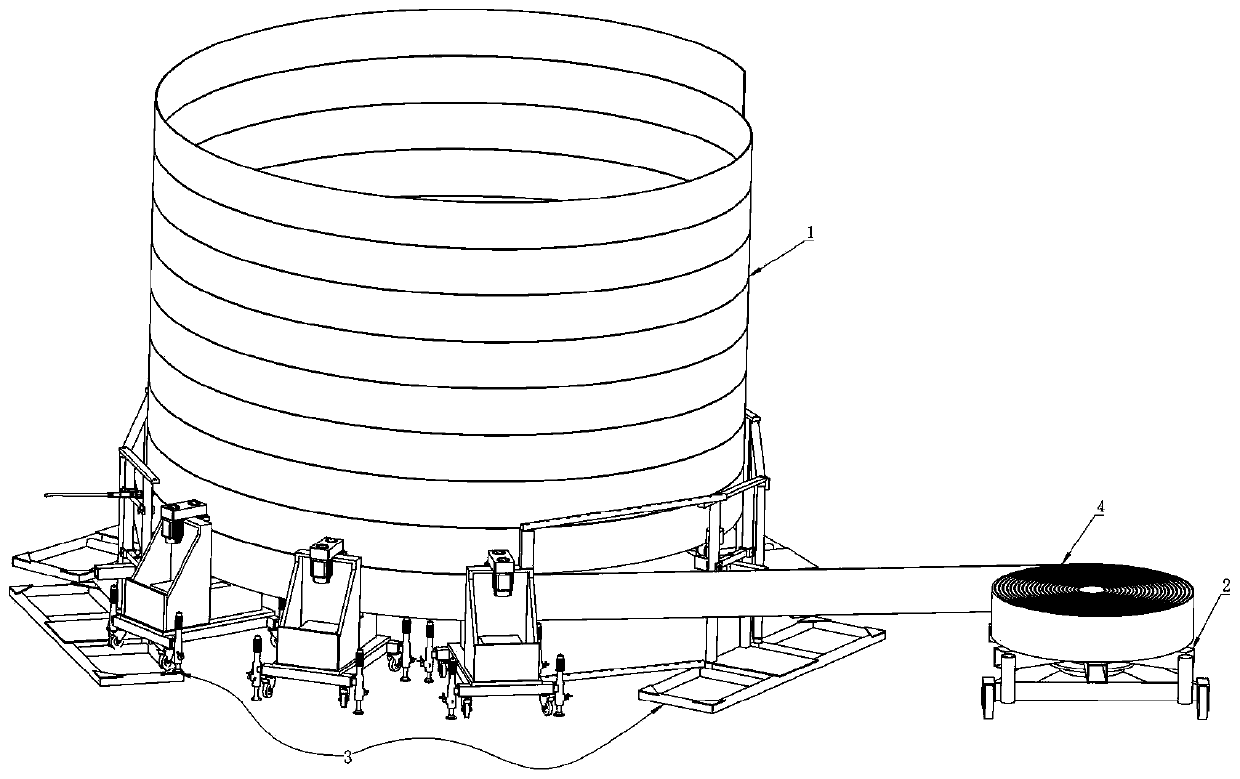

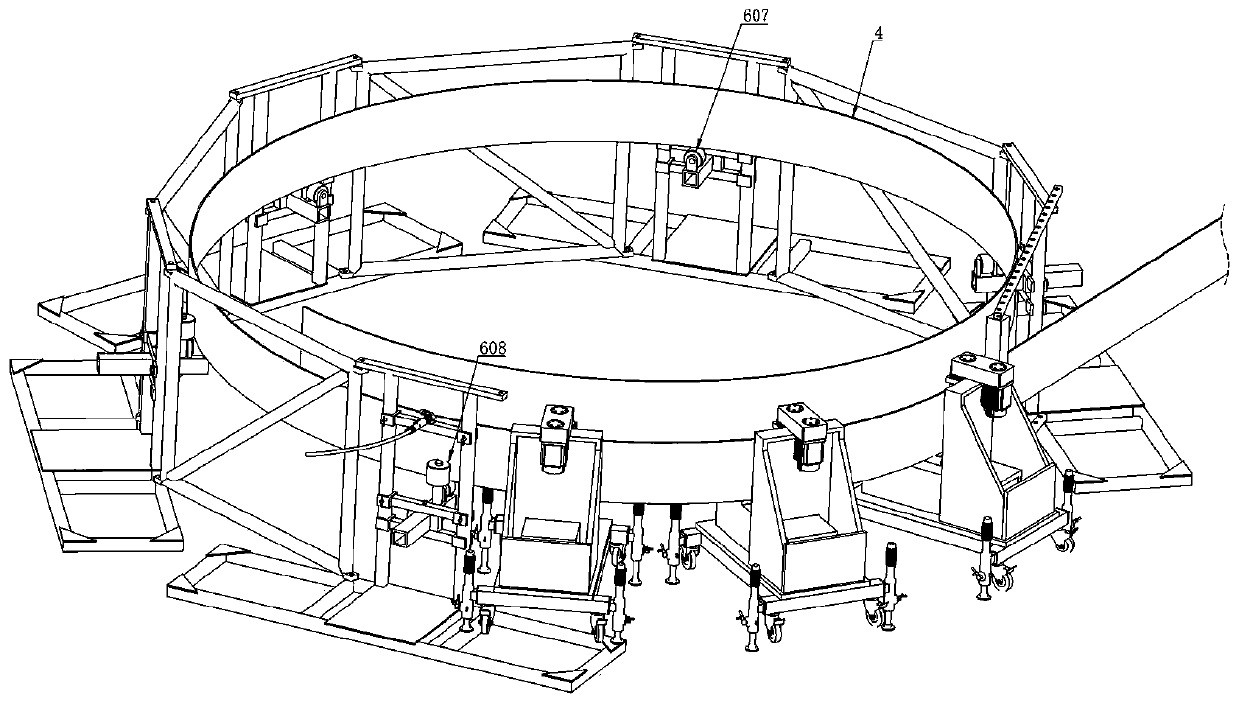

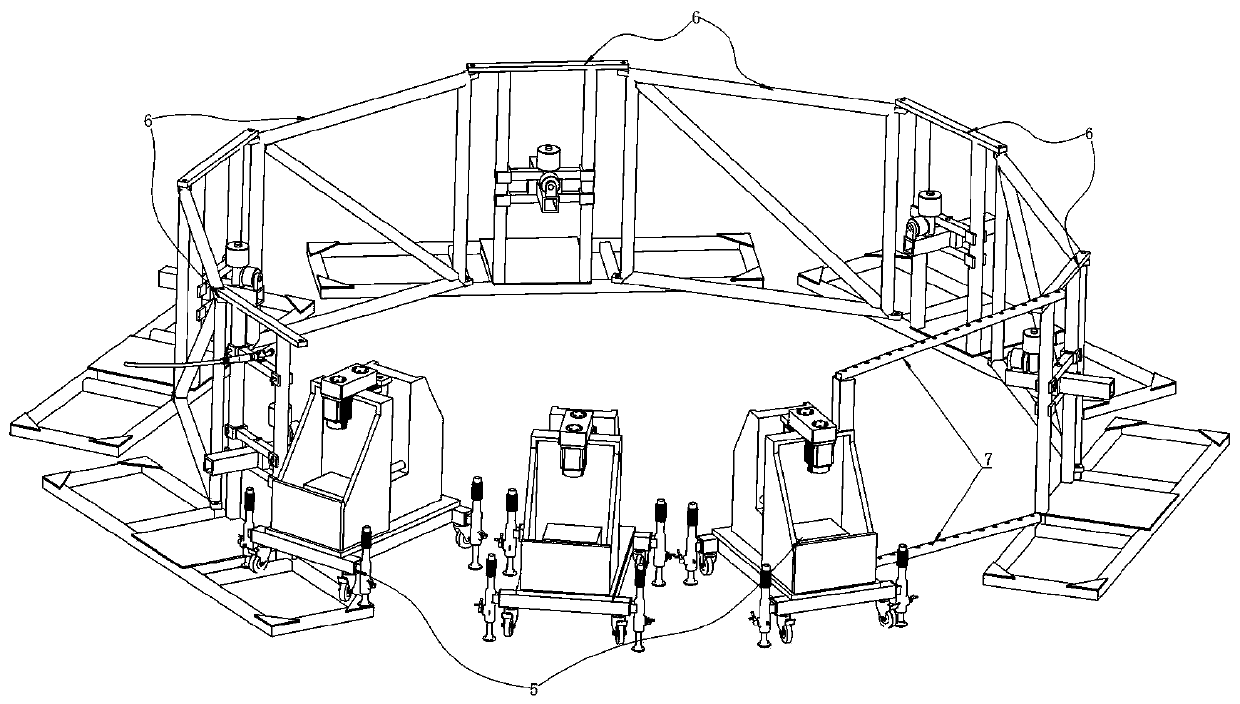

[0034] Specific implementation mode one: combine Figure 1-9 As shown, a fully automatic welding device for a spiral bin is characterized in that it includes a spiral bin 1, an unwinding machine 2 and a vertical lifting automatic welding device 3; One side; the uncoiler 2 is provided with a steel strip 4; the spiral bin 1 is welded by the steel strip 4; the vertical lifting type automatic welding device 3 includes a bending group 5, a bracket group 6 and supplementary The connecting rod 7; the bending group 5 is composed of a plurality of driving bending machines 501; the bracket group 6 is composed of a plurality of fixing frames 601, connecting frames 602 and brackets 603; Wheels 502 and legs 503 are raised.

[0035] Preferably, a gap 504 is provided above the middle of the drive bending machine 501; a gearbox 505 is fixedly installed on the top side of the gap 504 on the drive bender 501; a servo drive is fixedly installed on the input side of the gearbox 505. The motor 5...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap