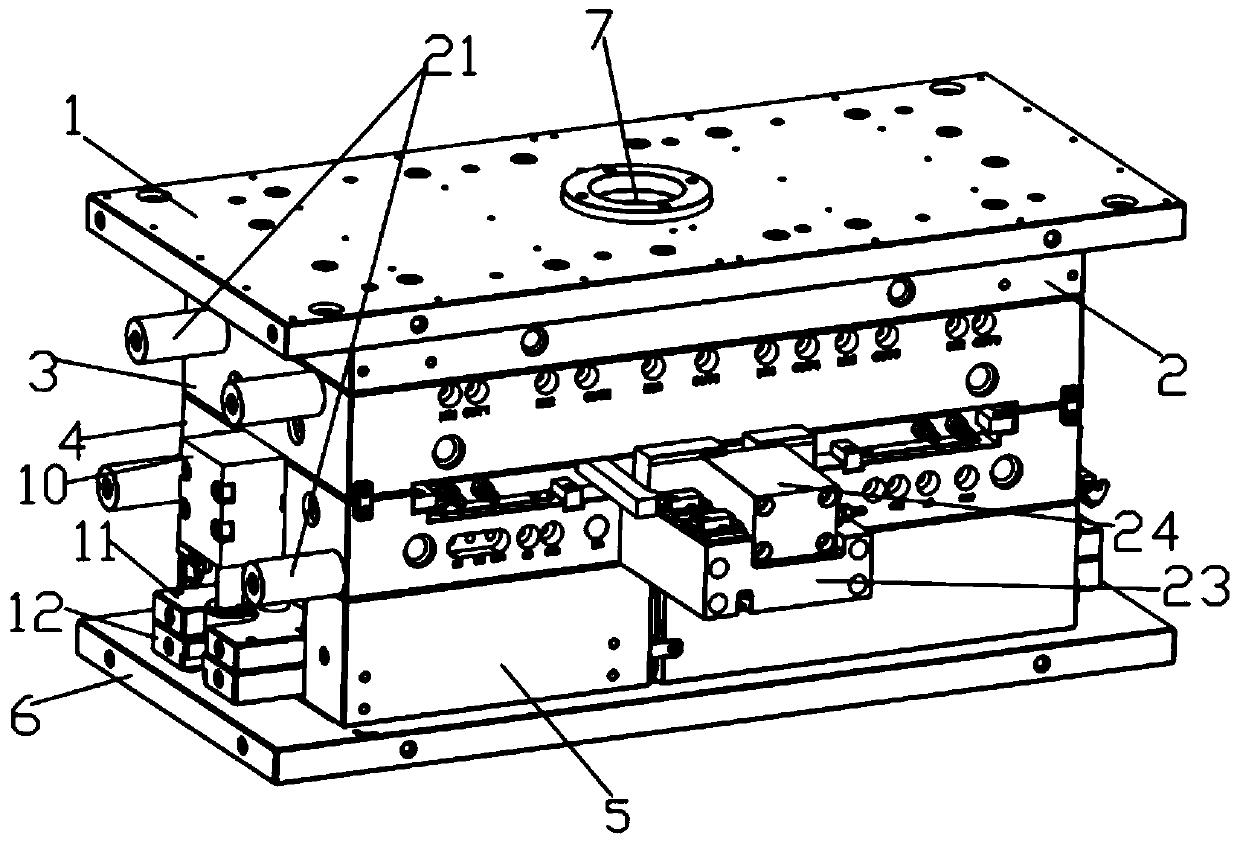

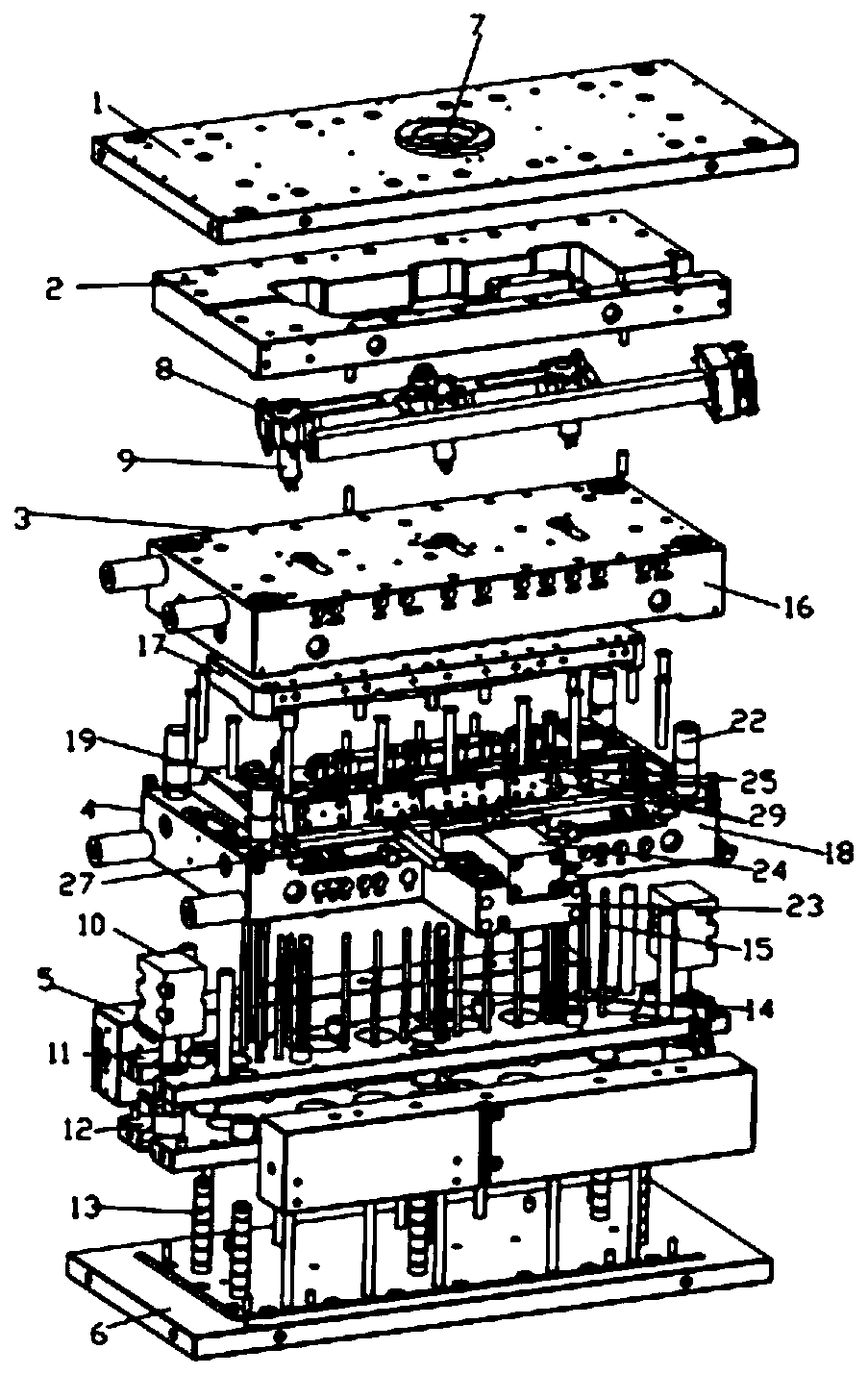

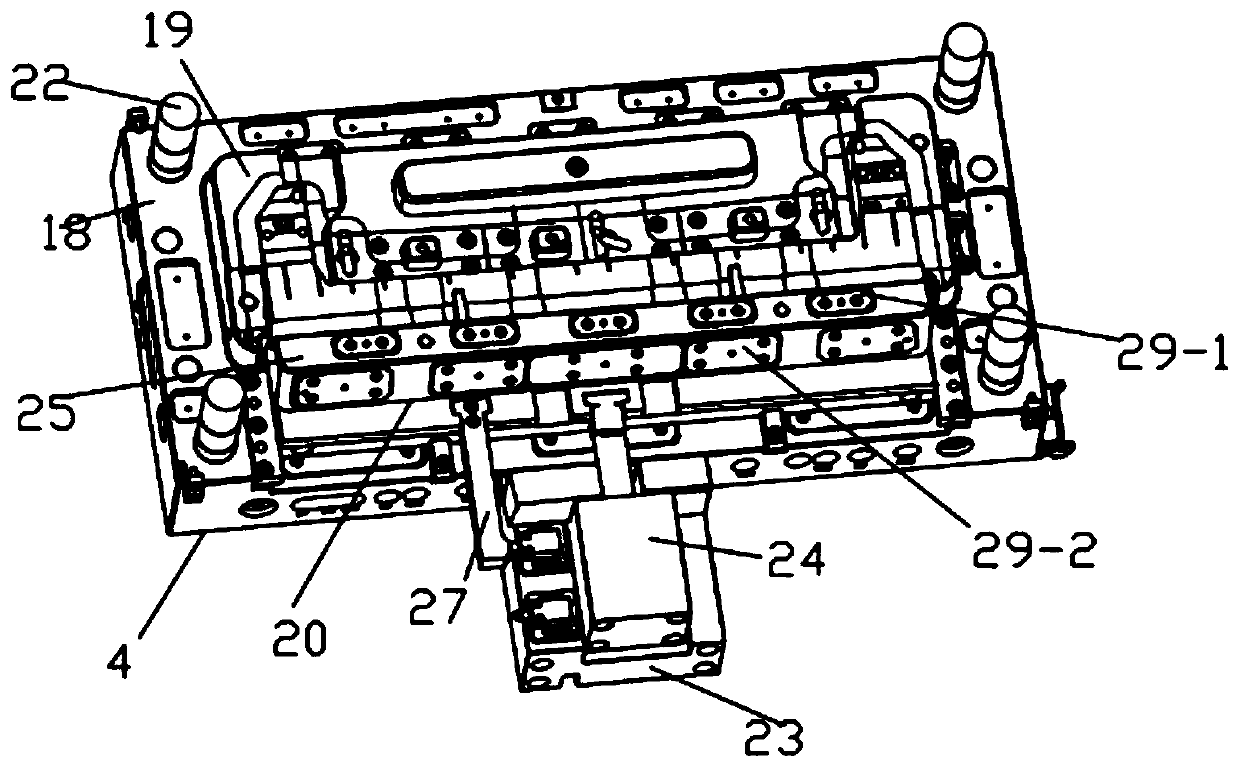

[0005] An injection mold for an automobile wind deflector, comprising a top plate, a

hot runner plate, a fixed mold mechanism, a movable mold mechanism, mold feet and a bottom plate, the bottom plate is connected with the movable mold mechanism through the mold feet, and the movable mold mechanism is located on the fixed mold Below the mechanism, the fixed mold mechanism is connected with the top plate through the hot runner plate, and the top plate is provided with a gate, and the gate is connected with a splitter plate, and the splitter plate is fixed in the hot runner plate, and the Two or more hot nozzles are arranged on the manifold, one end of the hot

nozzle communicates with the gate, the other end of the hot

nozzle communicates with the fixed mold mechanism and the movable mold mechanism, and the movable mold Between the mechanism and the bottom plate, there are an ejector cylinder, an upper ejector plate, a lower ejector plate and a top guide post, one end of the top guide post is fixed on the bottom plate, and the other end of the top guide post penetrates the lower ejector plate and the upper ejector plate, the upper ejector plate and the lower ejector plate are located inside the mold foot, and the upper ejector plate is located above the lower ejector plate, the lower ejector plate is located above the bottom plate, and the bottom plate It is fixedly connected with one end of the ejector cylinder, and the other end of the ejector cylinder is fixed on the left end of the movable mold mechanism, and the movable mold mechanism is located above the upper ejector plate, and the upper ejector plate is provided with a straight ejector block and an ejector pin One end of the thimble and one end of the straight ejector block are fixed on the upper ejector plate, the other end of the ejector pin and the other end of the straight ejector block pass through the movable mold mechanism, and since the gate is connected with a splitter plate, the The manifold is fixed in the hot runner plate, and the manifold is provided with two or more hot nozzles, one end of the hot

nozzle is connected to the gate, and the other end of the hot nozzle is connected to the fixed mold mechanism. It is connected with the movable mold mechanism, so that the plastic melt can flow into the splitter plate through the hot runner plate after entering the gate, and then flow in a balanced manner to the fixed mold mechanism and the movable mold mechanism for product molding, thereby improving work efficiency, and at the same time One end of the top guide post is fixed on the bottom plate, and the other end of the top guide post penetrates through the lower ejector plate and the upper ejector plate, the upper ejector plate and the lower ejector plate are located inside the mold foot, and the upper ejector pin The plate is located above the lower ejector plate, the lower ejector plate is located above the bottom plate, the bottom plate is fixedly connected to one end of the ejector cylinder, the other end of the ejector cylinder is fixed to the left end of the movable mold mechanism, and the movable mold mechanism The mold mechanism is located above the upper ejector plate, and the upper ejector plate is provided with a straight ejector block and an ejector pin, one end of the ejector pin and one end of the straight ejector block are fixed on the upper ejector plate, and the other end of the ejector pin is connected to the ejector pin. The other end of the straight ejector block runs through the movable mold mechanism, so that after the product is formed, the ejector cylinder drives the lower ejector plate and the upper ejector plate to move upward along the ejector guide column, and at the same time, the straight ejector block and ejector pin on the upper ejector plate The product is ejected, thereby solving the problem that the ejection mechanism of the traditional automobile wind deflector injection mold in the prior art adopts the inclined top method to cause the automobile wind deflector to be deformed during the whole inclined lifting process of the automobile wind deflector, so it needs to be operated Personnel assist to pry off the car wind deflector in the injection mold, which leads to the problem of low work efficiency, so the specific feature of improving work efficiency

Login to View More

Login to View More  Login to View More

Login to View More