Tobacco leaf conveying flow stabilizing and homogenizing device of belt conveyor

A belt conveyor, uniformity technology, applied in the direction of conveyor, conveyor objects, transportation and packaging, etc., can solve the problems of easy jamming of tobacco leaves, material blocking and shutdown, etc., achieve flexible and adjustable rake nail angle, and improve quality , the effect of improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] In order to make the technical solutions and beneficial effects of the present invention clearer, the preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings, so as to facilitate the understanding of technical personnel.

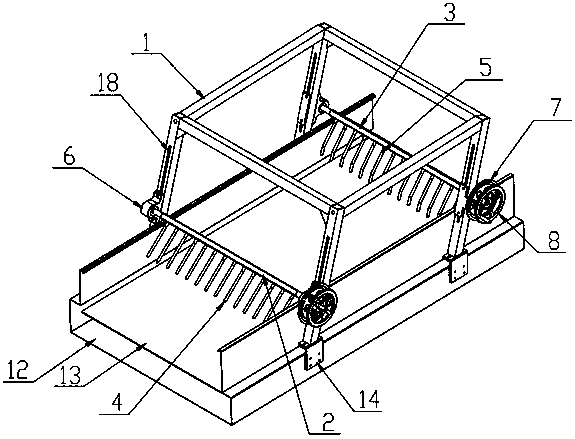

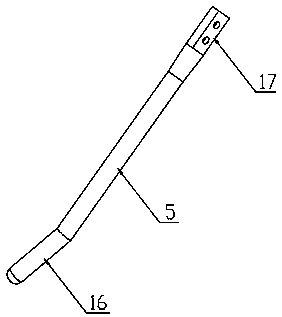

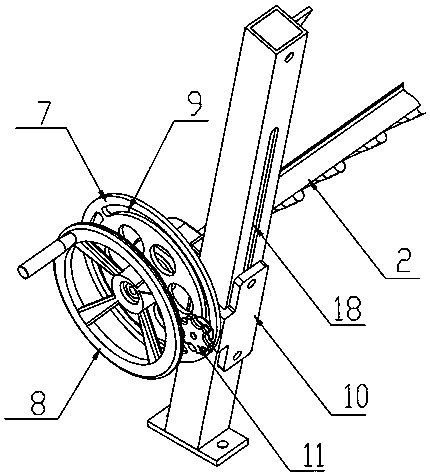

[0022] Such as Figure 1 to Figure 4 As shown, the device for stabilizing and uniforming the tobacco leaf conveying flow of the belt conveyor includes a main frame 1, and the four legs of the main frame 1 are respectively installed on the conveyor frame 18 through the mounting blocks 14, and the upper front side of the main frame 1 and the The front equalizing rod 2 and the rear equalizing rod 3 are respectively installed on the legs on the rear side. Straight-toothed rake nails 4 and folded-toothed rake nails 5 are arranged at equal intervals on the front equalizing rod 2 and rear equalizing rod 3 respectively. The material rod 2 and the rear equalizing rod 3 have a square section...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com