Tension adjusting mechanism and insulated wire producing device

A technology of tension adjustment mechanism and frame, which is applied in the directions of transportation and packaging, delivery of filamentous materials, and thin material processing, etc. It can solve problems such as broken wires and sudden changes in wire tension, and achieves the goal of improving processing efficiency and reducing breakage The effect of risk and flexible adjustment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] When the wire is processed to produce the insulated wire, the wire needs to have a certain tension so that the insulating material can be coated or wrapped on the surface of the wire. In the prior art: a plurality of rollers are used to increase the frictional resistance of the wire transmission by winding the wire around the plurality of rollers in turn, so that the wire has a certain tension. Factors such as the rotation of the rolling wheel or the rough change of the wire surface lead to a sudden change in the tension force, and there is a serious risk of wire breakage. The equipment is shut down and adjusted, which leads to problems such as low processing efficiency.

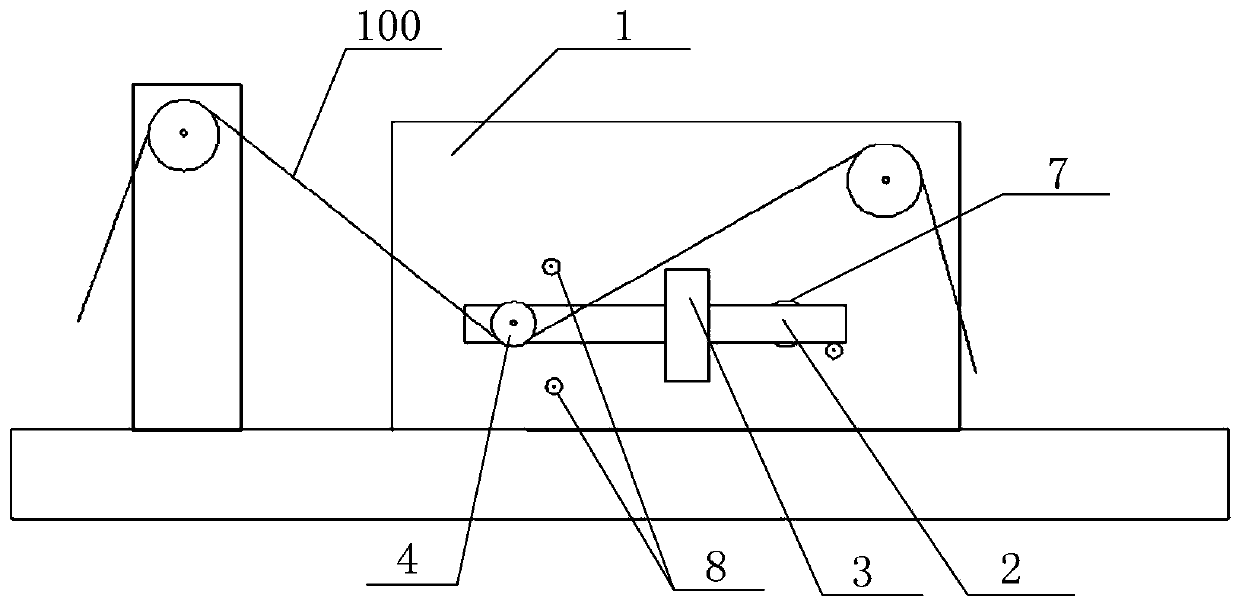

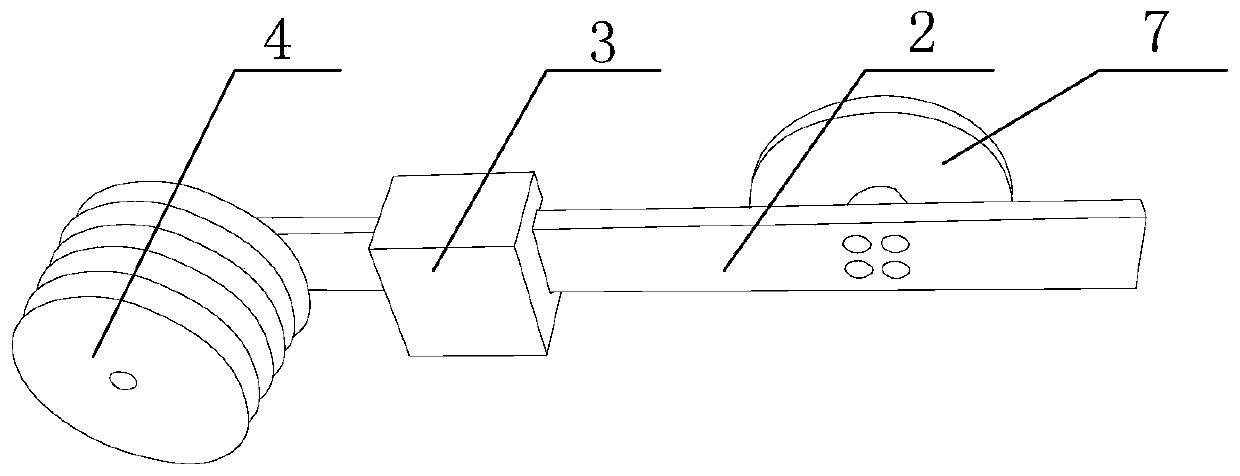

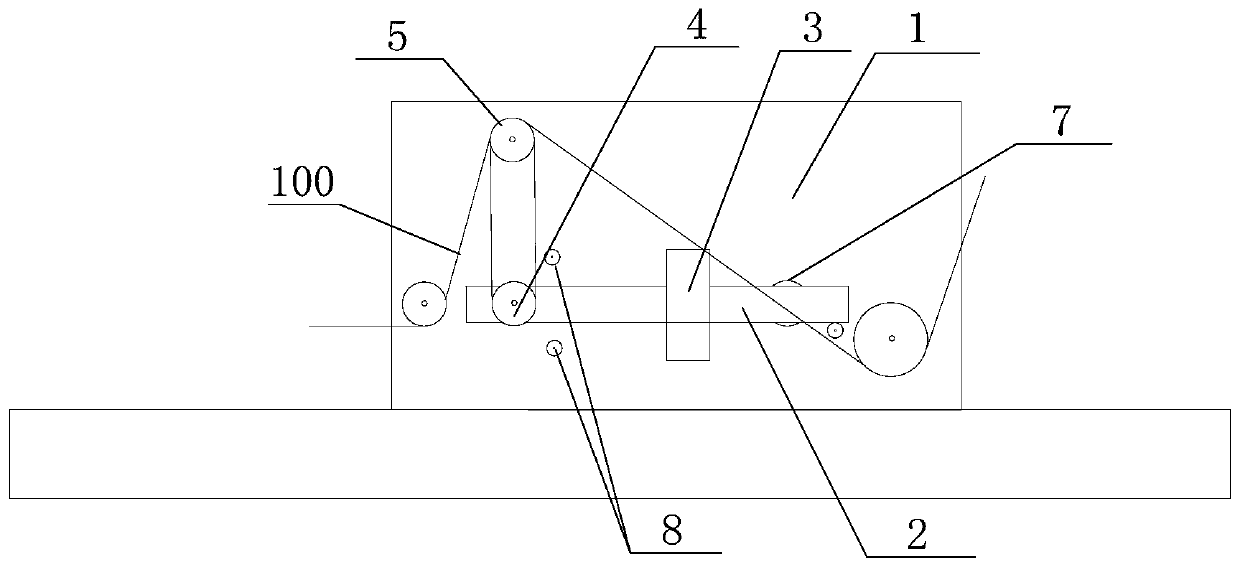

[0038] In contrast, this embodiment provides a tension adjustment mechanism, refer to figure 1 , the tension adjustment mechanism includes a frame 1 , a swing arm 2 , a slider 3 and a roller 4 . Specifically, the swing arm 2 is rotatably installed on the frame 1; the roller 4 is rotatably installed ...

Embodiment 2

[0049] This embodiment provides an insulated wire production device, and the insulated wire production device includes the tension adjustment mechanism provided by any one of the optional implementations of the first embodiment.

[0050] Since the insulated wire production device provided in this embodiment includes the tension adjustment mechanism described in the first embodiment, the insulated wire production device provided in this embodiment can achieve all the beneficial effects that can be achieved by the tension adjustment mechanism in the first embodiment, specifically , refer to figure 1 , the tension adjustment mechanism includes a frame 1 , a swing arm 2 , a slider 3 and a roller 4 . Specifically, the swing arm 2 is rotatably installed on the frame 1; the roller 4 is rotatably installed on the swing arm 2, and the rotating shaft of the roller 4 and the rotating shaft of the swing arm 2 are spaced apart from each other along the extending direction of the swing arm ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com