Blast furnace charging bucket material receiving and distribution device

A material distributing device and material tank technology, applied in the direction of bell and funnel arrangement, etc., can solve the problems of increased maintenance costs and equipment accident risks, wear of the center column body and liner, wear of the center column body of the vertical material tank, etc., to meet the requirements Long-term operation requirements, solve the effect of fast wear and less types of wearing parts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention is described in further detail now in conjunction with accompanying drawing.

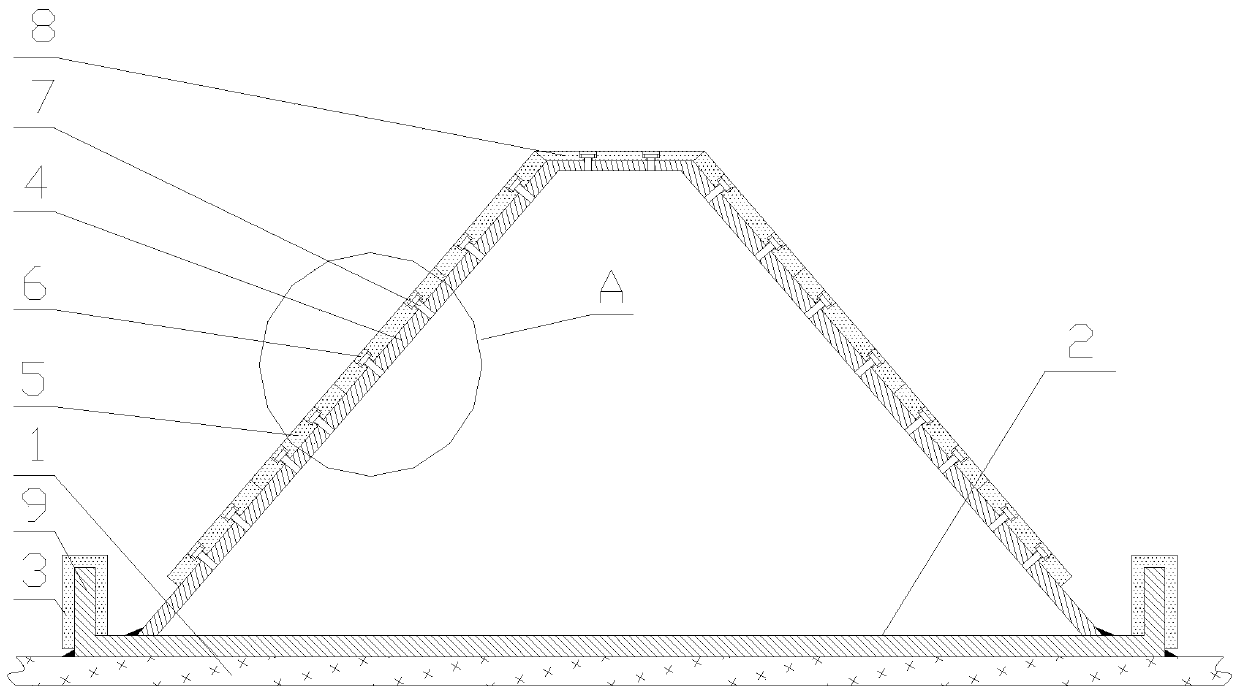

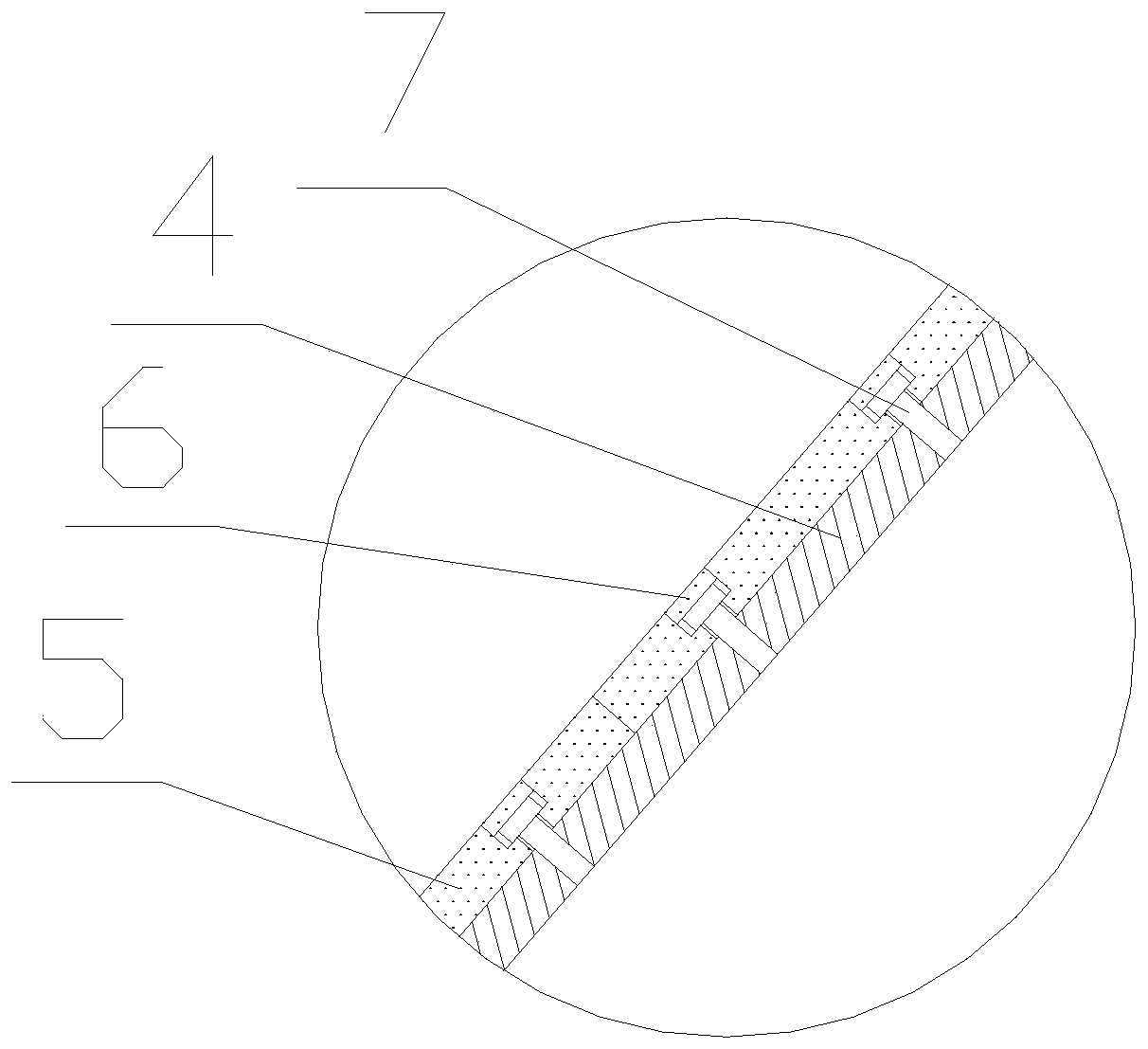

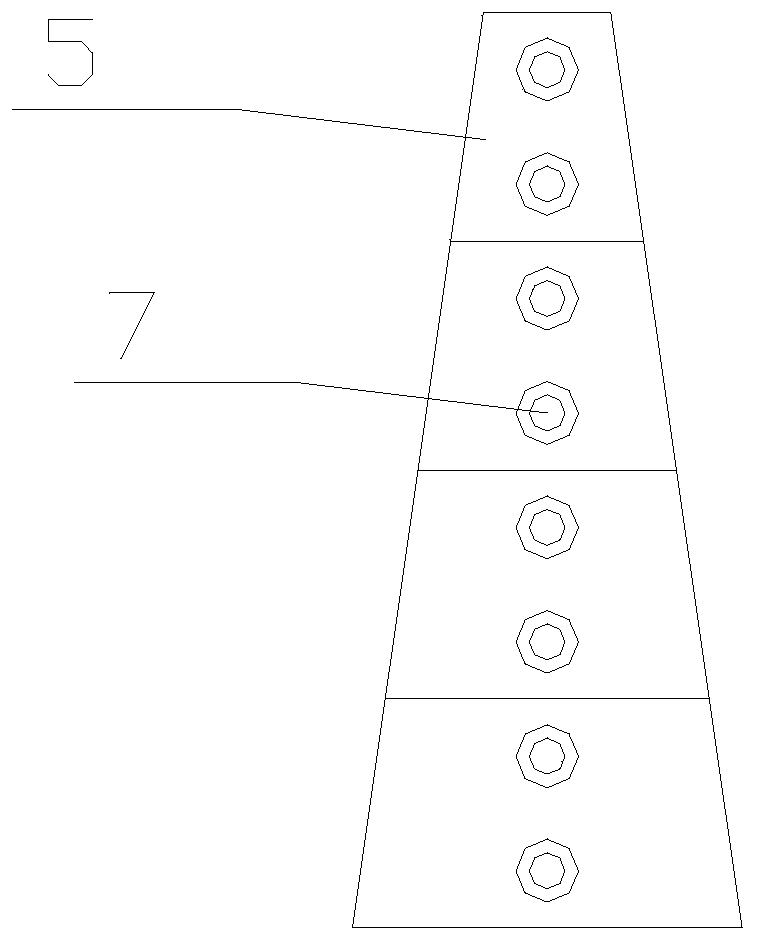

[0020] like figure 1 , 2 As shown, a blast furnace charging tank connecting and distributing device includes a charging tank center column 1, a chassis 2, a chassis ceramic liner 3, and a front prism 4, and the chassis 2 is welded on the charging tank center column 1, and the chassis 2 and The central column 1 of the material tank is concentrically fixed. The bottom of the prism 4 is fixed in the chassis 2, and the outer periphery of the chassis 2 is provided with an integrally formed baffle 9, the chassis 2 and the baffle 9 are integrally formed, and the prism 4 and the chassis 2 are integrally cast, or they can be cast separately It is connected by stainless steel wear-resistant electrode welding, the inner wire bolt hole is processed, and the surface is polished at high points. Chassis 2, front edge platform 4, and fastening bolt 7 are all made of 1Cr18Ni9Ti stainl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com