Single-circuit 500kV and double-circuit 220kV mixed-voltage large-span terminal branch tower

A large-span and branching technology, applied in the direction of tower, cable space arrangement/configuration, building type, etc., can solve problems such as difficulty, large floor space, and increased transmission line path selection, to reduce floor space and transmission capacity. Large, huge social and economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments.

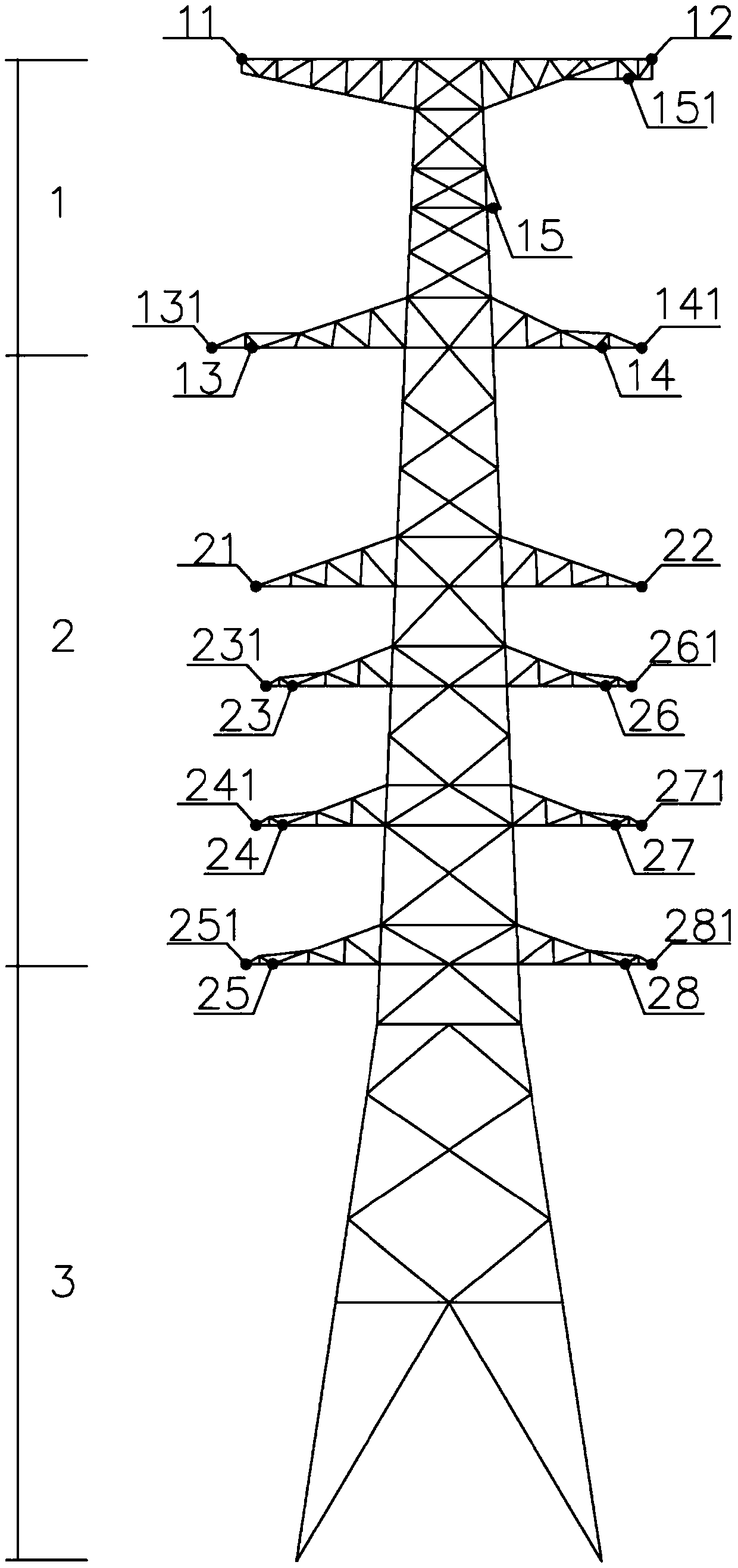

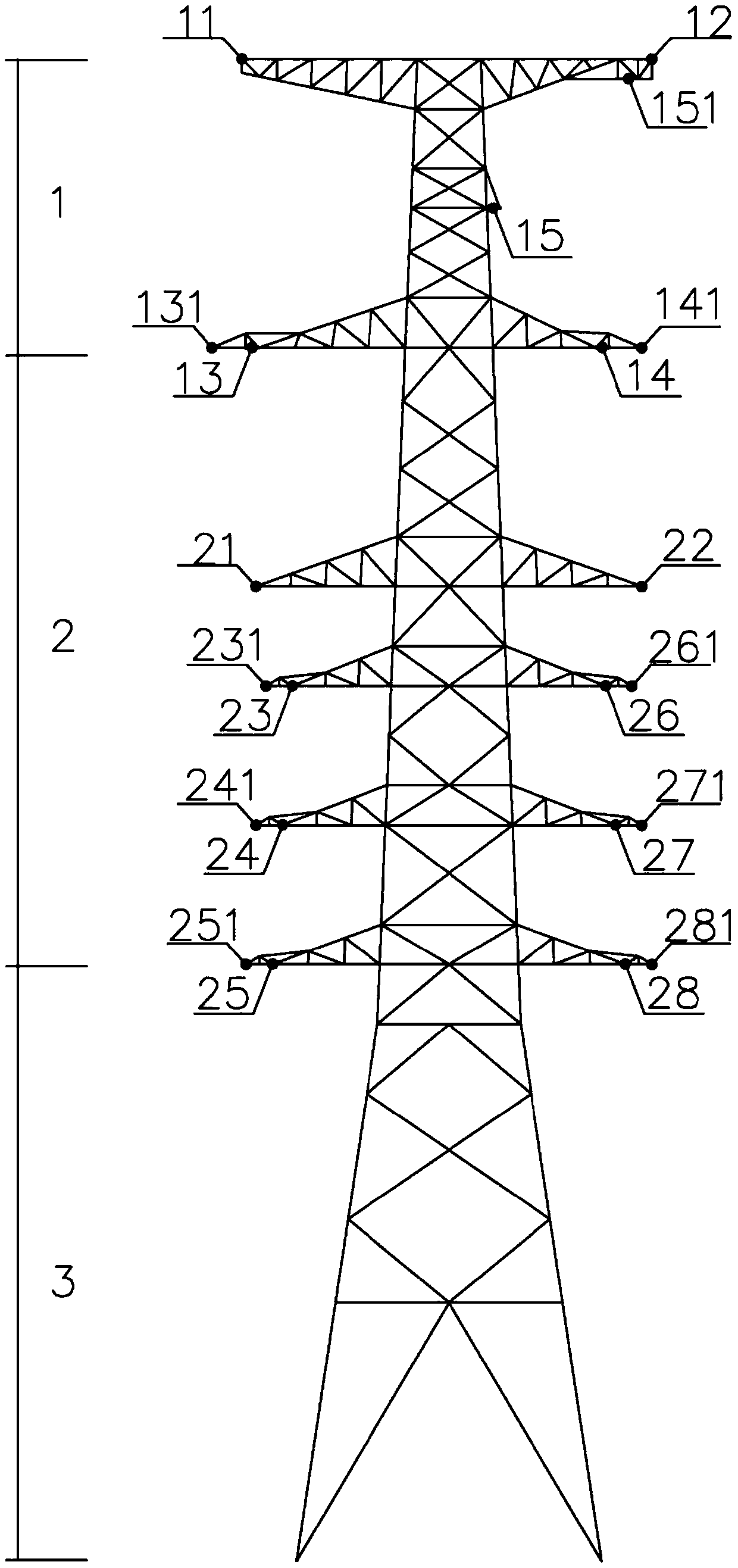

[0014] Refer to attached figure 1 , this embodiment includes a tower head and a tower body 3. The tower head includes a 500kV tower head I1 and a 220kV tower head II2 located at the upper and lower ends respectively. The tower head I1 has an "I"-shaped structure, and the tower head II2 has an "umbrella" shape Structure, the tower head is equipped with ground wire hanging points, wire hanging points, and jumper wire hanging points. In order to facilitate the distinction, the two sides of the tower head I1 and the tower head II2 are divided into left and right sides.

[0015] The left and right ground wire hanging points 11 and 12 on the left and right sides of the top of the tower head I1 are respectively provided for hanging ground wires, and the middle phase jumper hanging point 151 is also provided on the right side of the top; The left sid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com