Tri-proof lamp facilitating aloft work

A high-altitude operation and three-proof lamp technology, which is applied to the damage prevention measures of lighting devices, air-proof/waterproof devices, and parts of lighting devices. And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

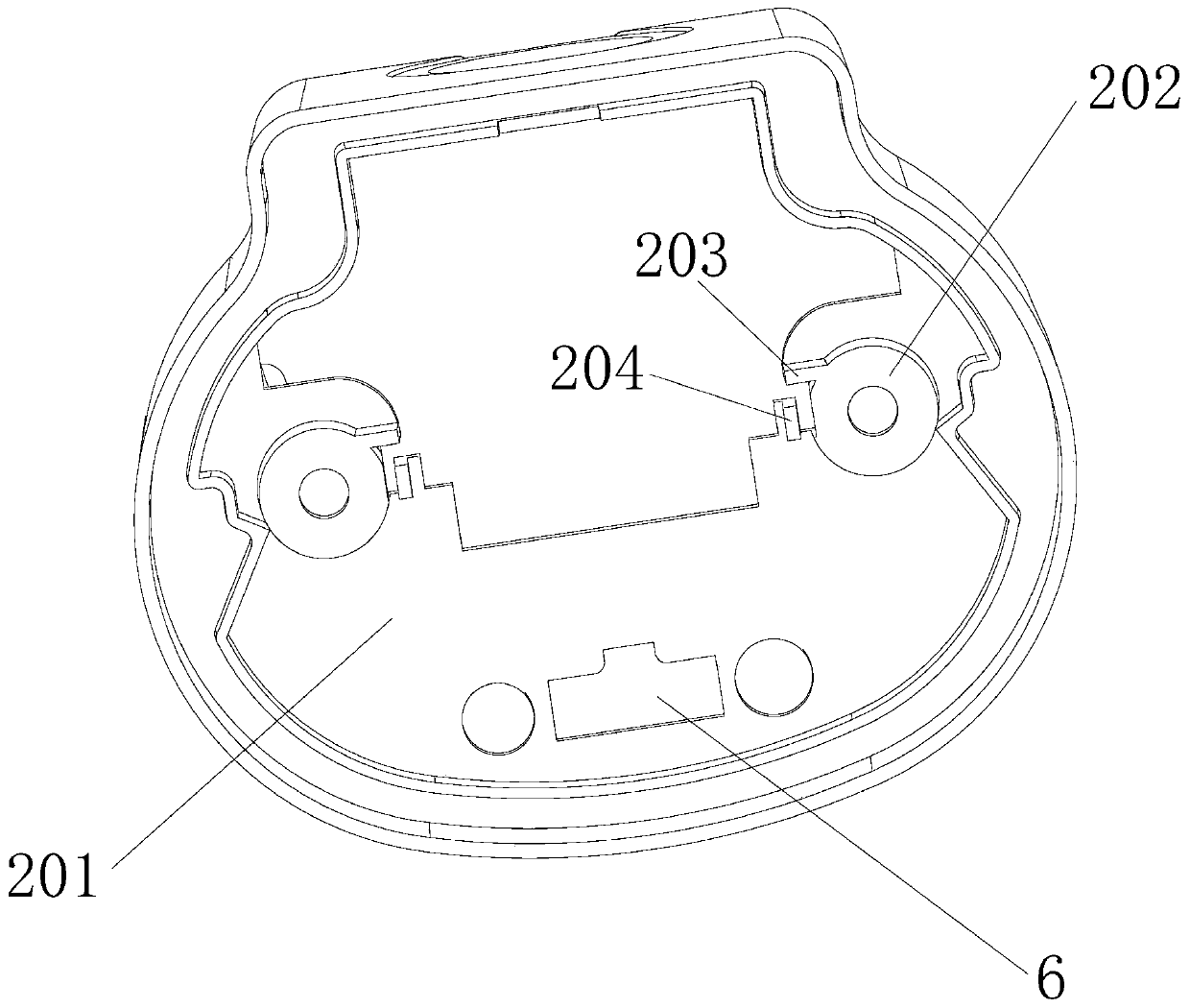

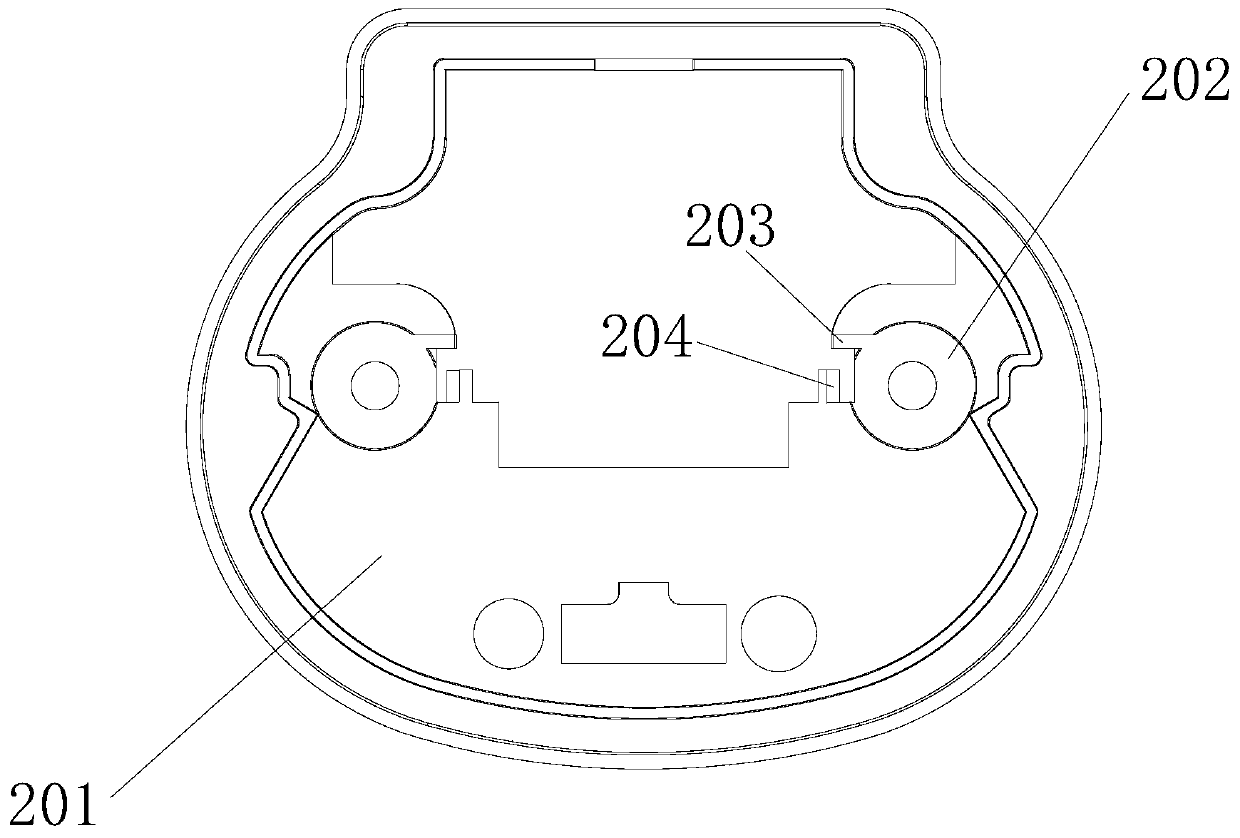

[0031] The present invention will now be further explained in conjunction with the drawings. These drawings are simplified schematic diagrams only to illustrate the basic structure of the present invention in a schematic manner, so they only show the configuration related to the present invention.

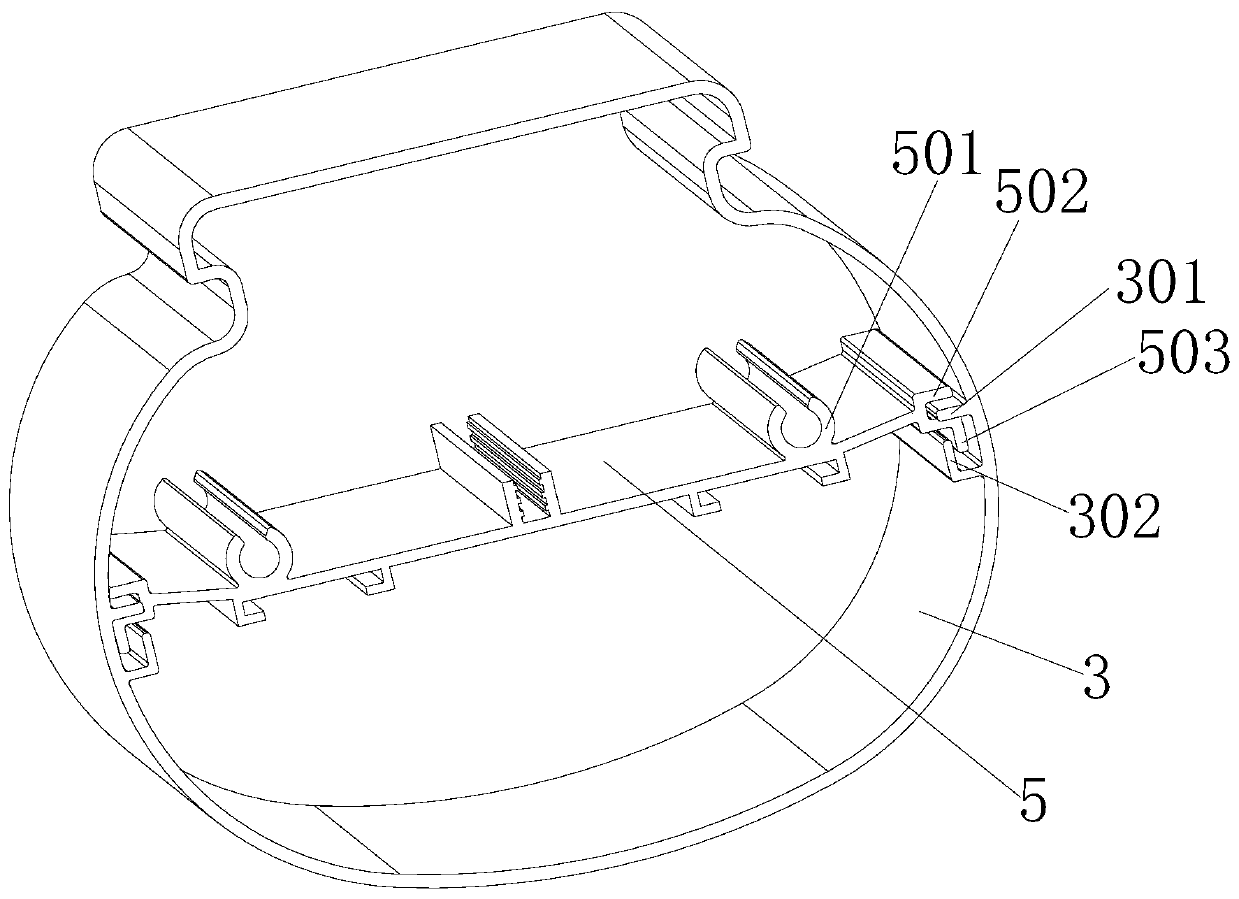

[0032] Such as figure 1 As shown, a tri-proof lamp that is convenient for high-altitude operations has a tube housing 3, the tri-proof lamp further has a push-pull groove plate 5, and the edge of the push-pull groove plate 5 is symmetrically provided with first push-pull grooves, The first push-pull groove is enclosed by a first horizontal guide rail 502 and a first L-shaped guide rail 503, the first push-pull groove is a horizontal guide groove; the tube wall of the lamp housing 3 is symmetrically provided with a second push-pull groove , The second push-pull groove is enclosed by a second horizontal guide rail 301 and a second L-shaped guide rail 302, the second push-pull groove is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com