Large workpiece detection platform with inner hole

A large-scale workpiece and detection platform technology, applied in the direction of workbench, workpiece clamping device, measuring device, etc., can solve the problems of disconnected measurement and adjustment, time-consuming and labor-intensive problems, and achieve the effect of high reliability and flexible adjustment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The specific implementation manners of the present invention will be described in further detail below in conjunction with the accompanying drawings.

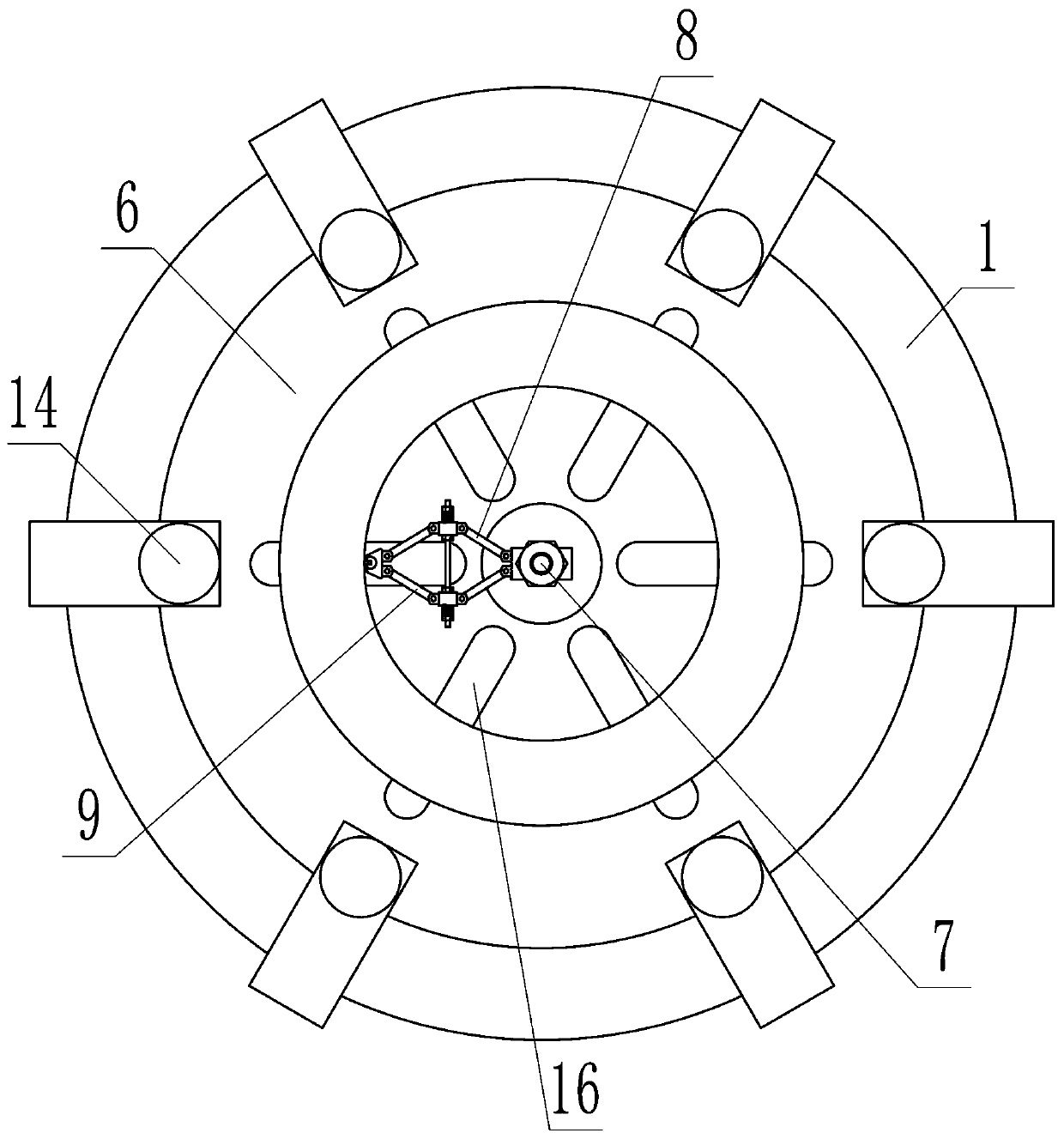

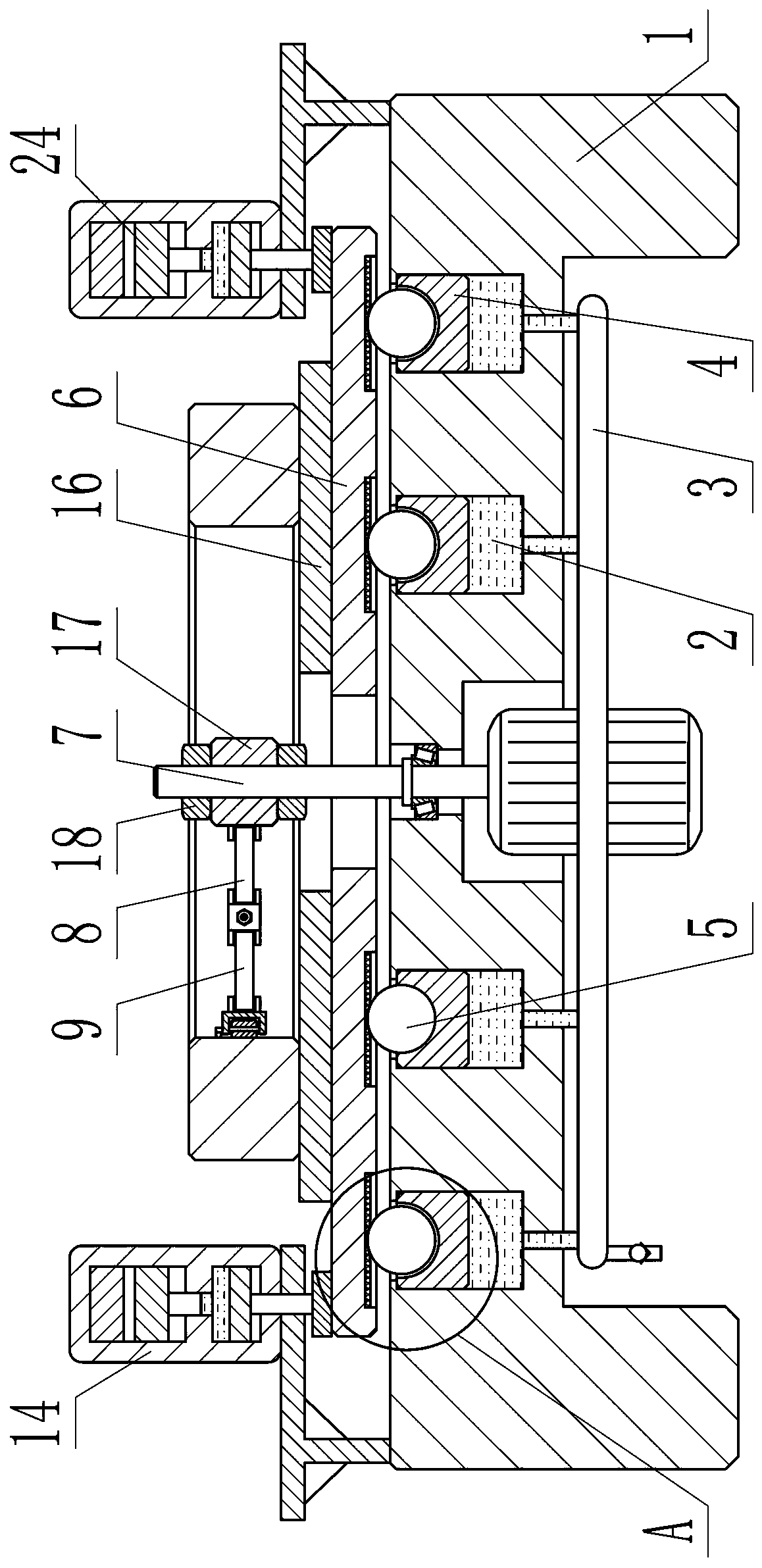

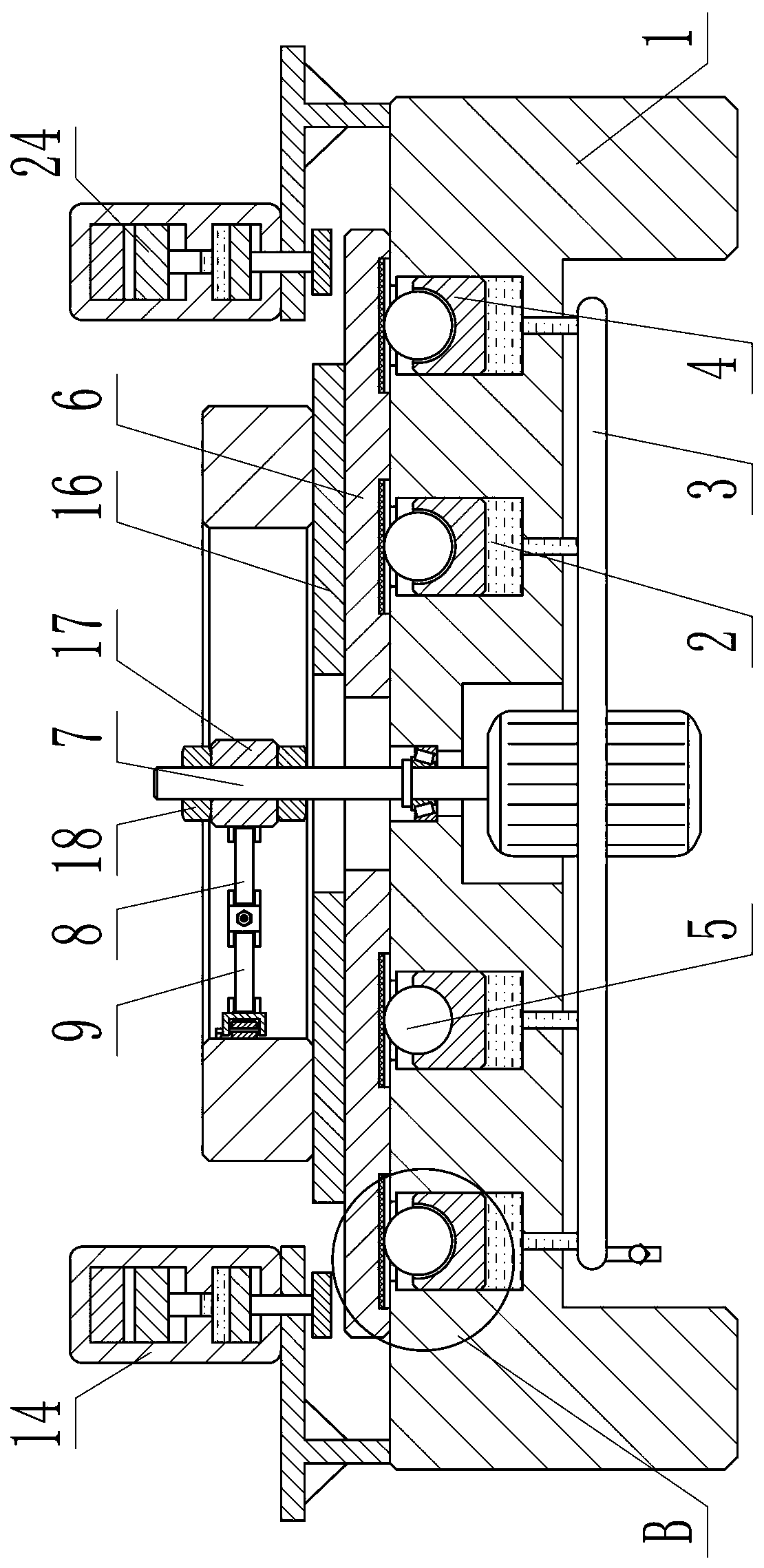

[0015] Depend on Figure 1 to Figure 8 Provided, the present invention includes a horizontal base 1, a plurality of vertical blind holes 2 are uniformly distributed on the upper surface of the base 1, and an oil supply pipe 3 communicating with the bottom of the plurality of blind holes 2 is provided under the base 1, and each blind Each hole 2 is equipped with a block 4 that fits its inner wall, and the upper end of each block 4 is embedded with a ball 5 that can roll freely. A horizontal ring-shaped loading plate 6 is provided above the base 1. A plurality of stoppers 4 can be moved up to hold up a plurality of balls 5 and a loading plate 6; a vertical rotating shaft 7 is installed in the center of the base 1, and the upper end of the rotating shaft 7 passes through the ring hole of the loading plate 6, and a rotating ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com