Electrical construction suspender with automatic adjusting function

An automatic adjustment and electrical construction technology, applied in the direction of overhead line/cable equipment, etc., can solve the problems of high labor intensity of construction personnel, slow adjustment efficiency, and unsafe construction, and achieve the effect of fast fixing efficiency, convenient construction and safe construction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

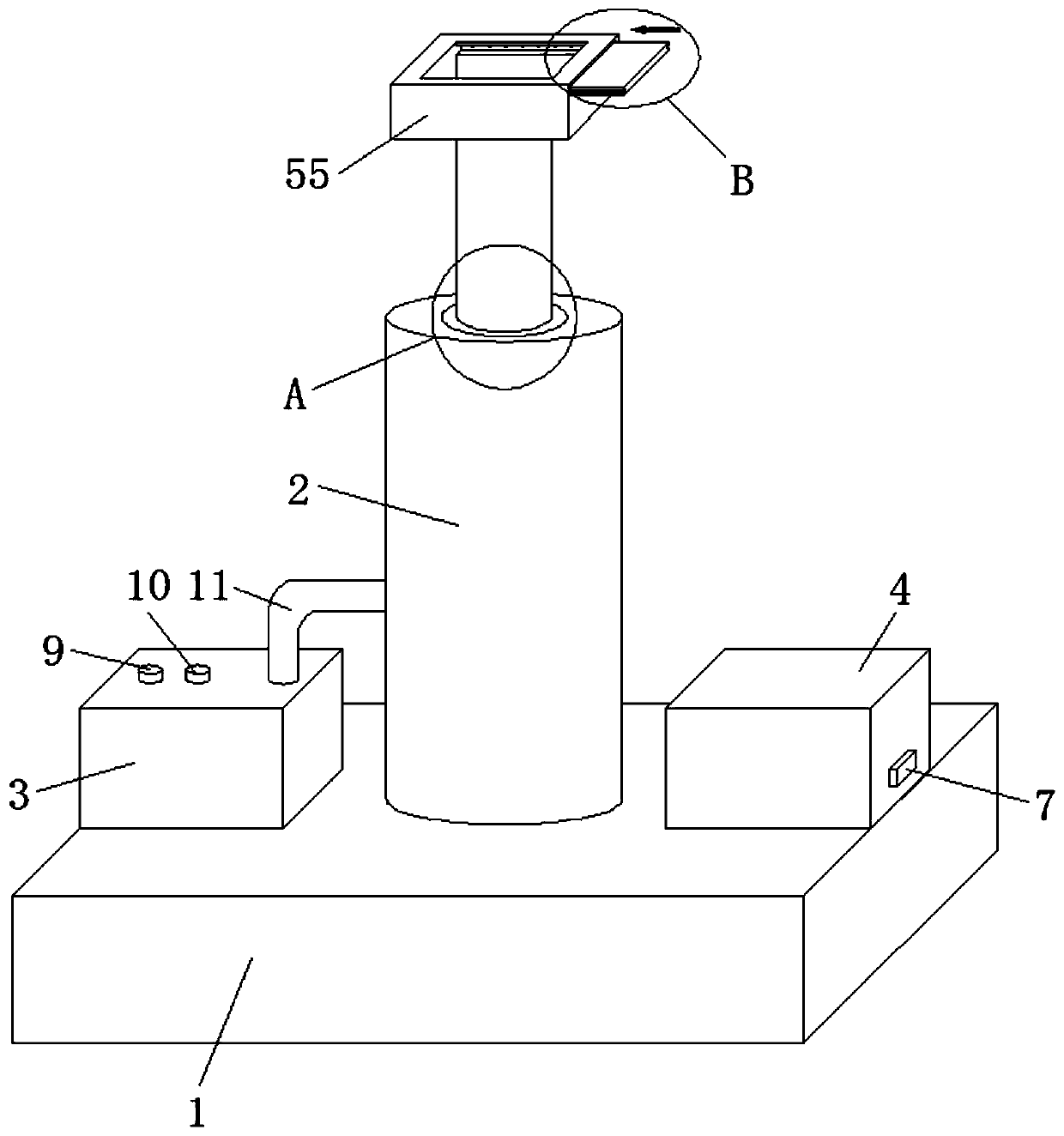

[0040] The following is attached Figure 1-8 The present invention is described in further detail.

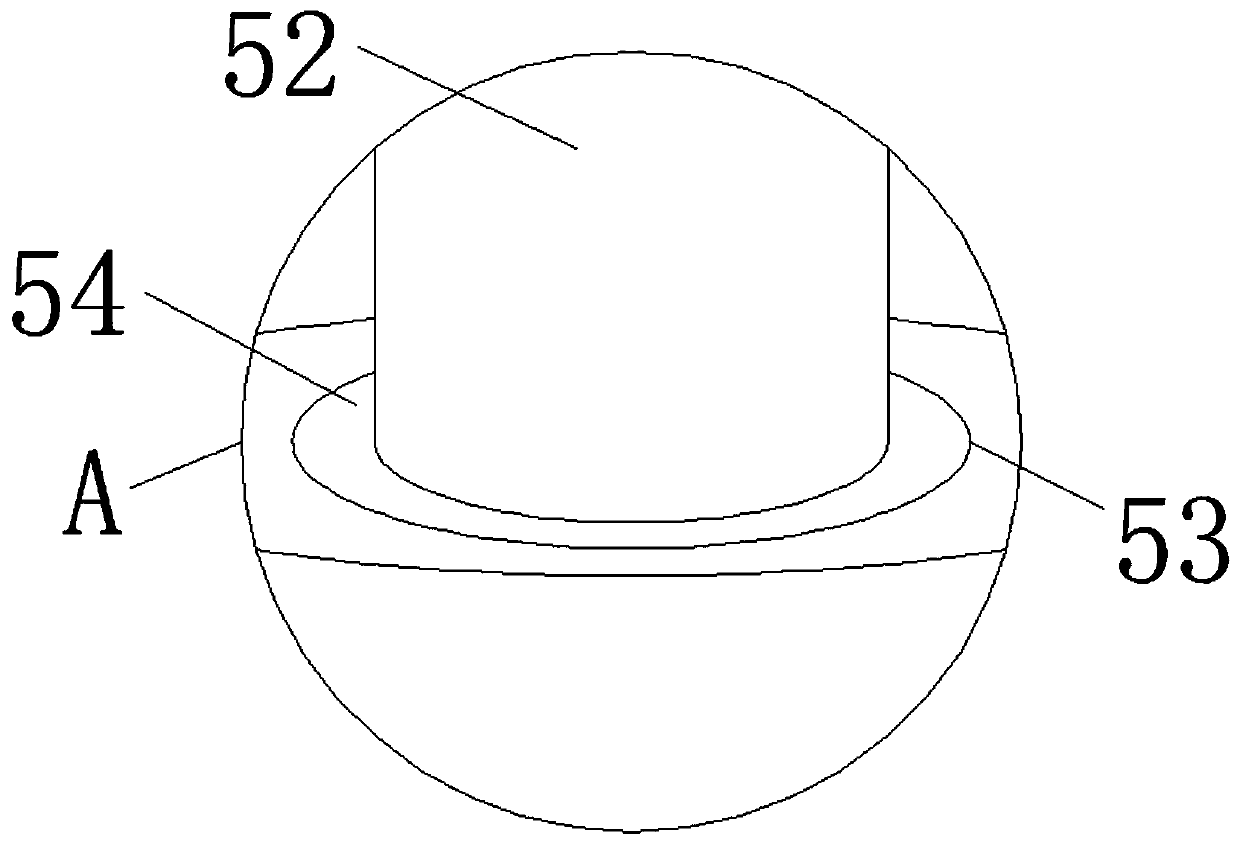

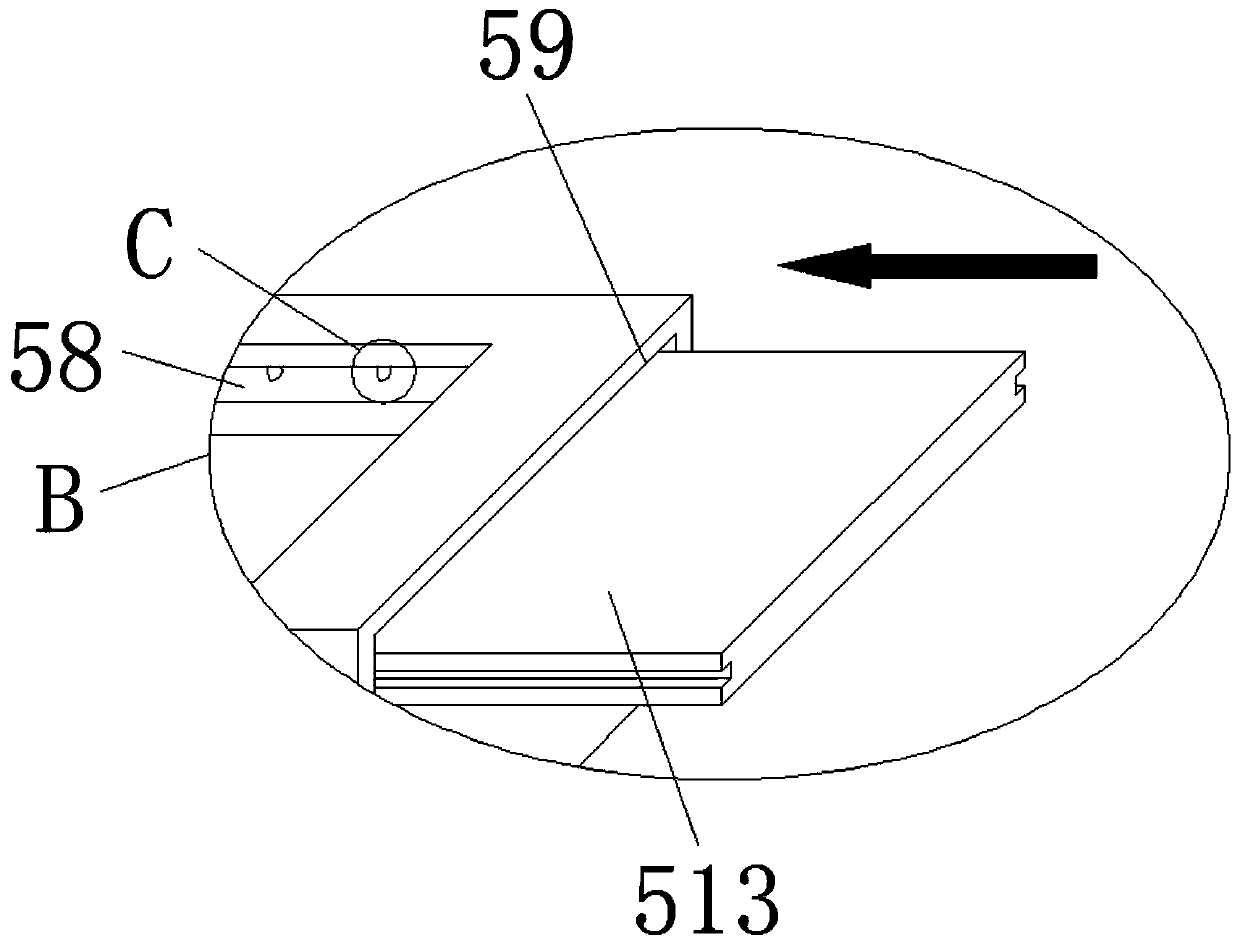

[0041] 一种具有自动调节功能的电气施工用吊杆,如 Figure 1-8As shown, including a support block 1, the upper surface of the support block 1 is respectively fixedly connected with a support rod 2, a small electric air pump 3 and a battery box 4, the support rod 2 is located between the small electric air pump 3 and the battery box 4, and the support rod 2 An automatic adjustment mechanism is provided inside, and the automatic adjustment mechanism includes a cavity 5, and the inside of the support rod 2 is provided with a cavity 5;

[0042] Such as figure 1 with Image 6 As shown, further, the small electric air pump 3 includes an air charging switch 9 and an air extraction switch 10, both the air charging switch 9 and the air extraction switch 10 are electrically connected to the small electric air pump 3, and the air outlet of the small electric air pump 3 is fixedly communicated with a L The t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com