Making process of mozzarella cheese and forming device applied in making process

A production process and a molding device technology, applied in the field of mozzarella cheese production process and its molding device, can solve problems such as low cheese production efficiency, and achieve the effects of improving production efficiency, reducing pollution and realizing safety.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

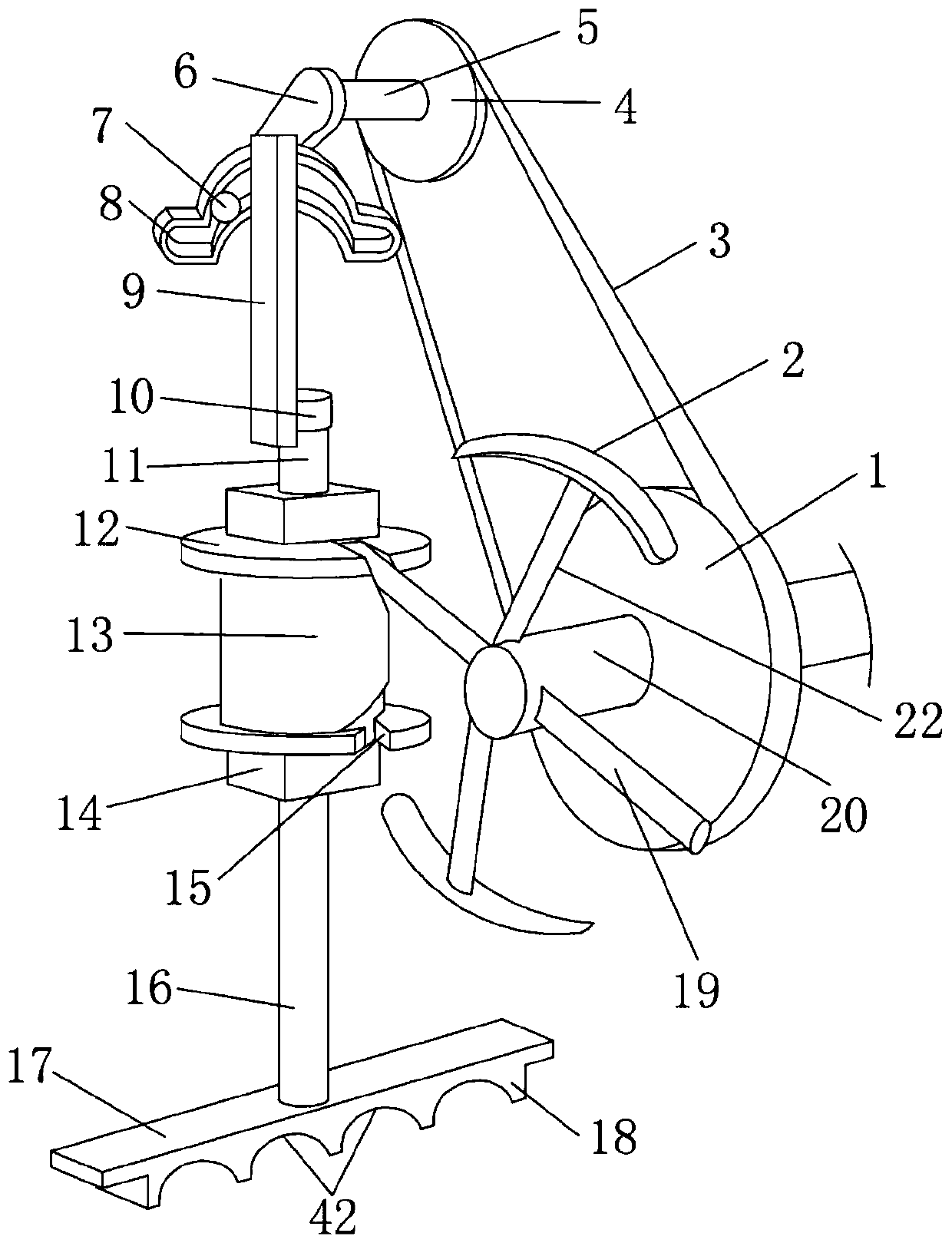

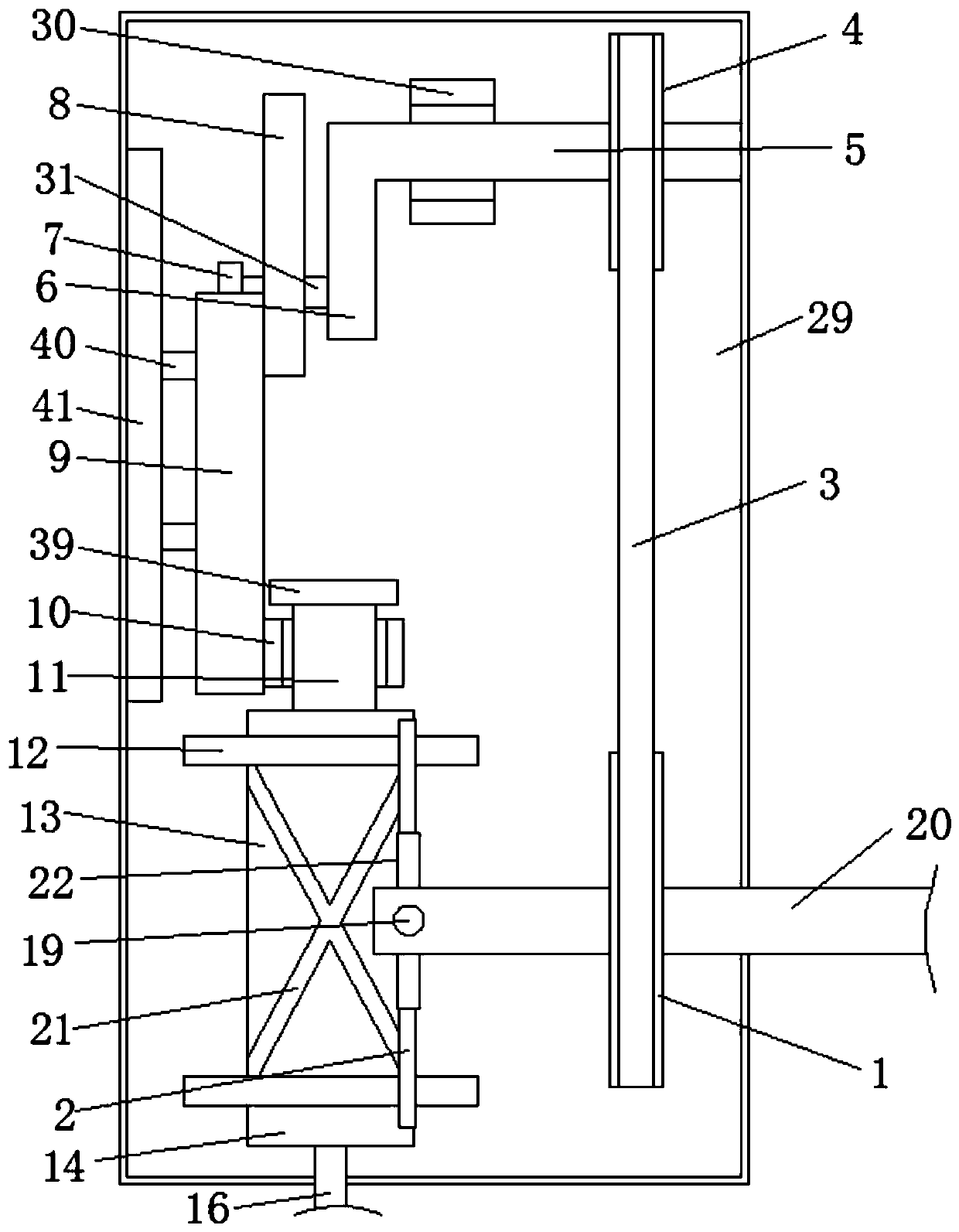

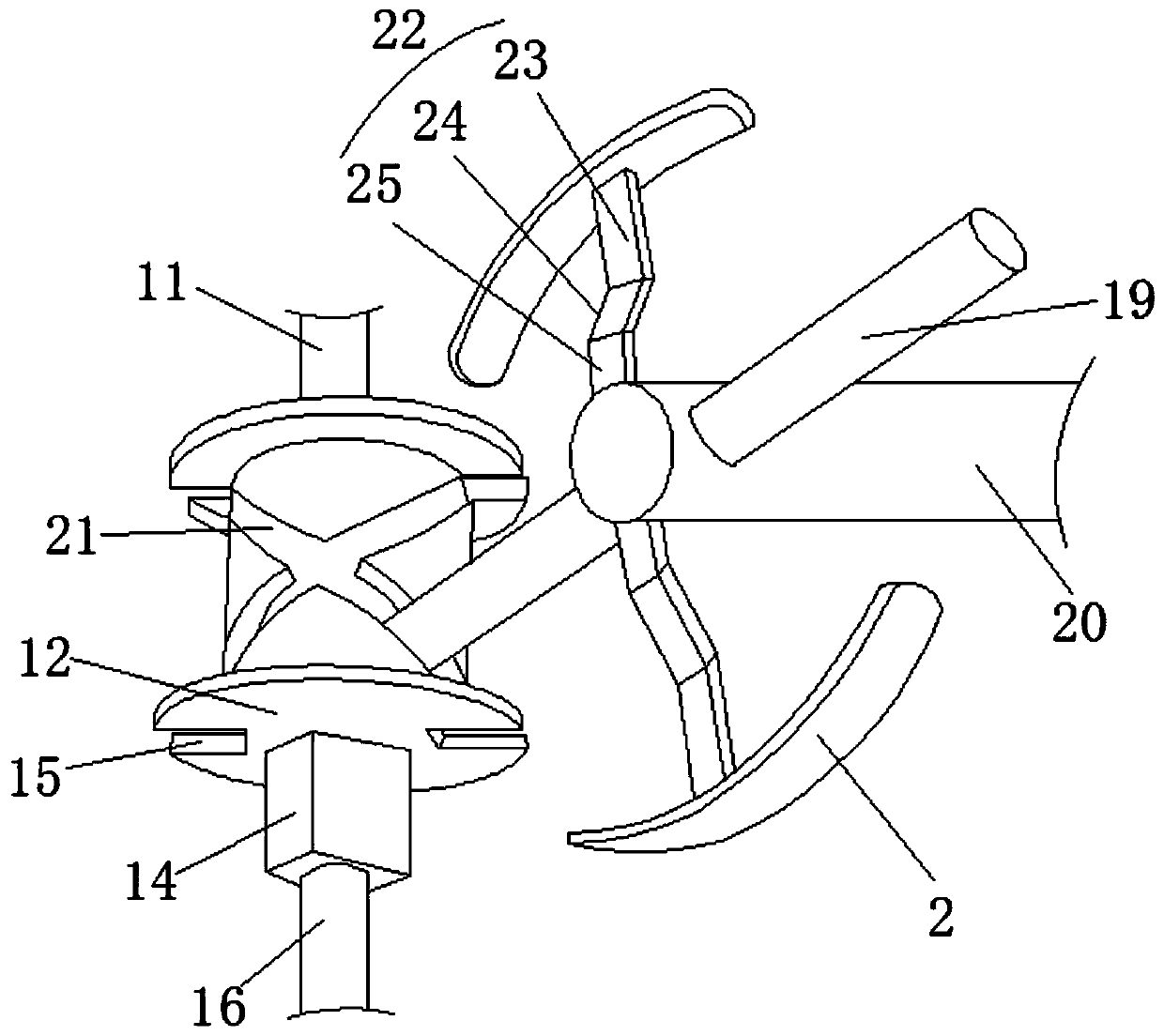

[0036] The preferred embodiments of the present invention will be described below in conjunction with the accompanying drawings. It should be understood that the preferred embodiments described here are only used to illustrate and explain the present invention, and are not intended to limit the present invention.

[0037] The embodiment of the present invention provides a kind of manufacturing technology of mozzarella cheese, comprises the following steps:

[0038] Step 1, sterilizing and ripening the milk;

[0039] Step 2, utilizing milk to prepare curds;

[0040] Step 3, the curd block is piled and cut multiple times with a forming device to form curd block particles;

[0041] Step 4, using a stirring device to stir and dehydrate the curd particles to form cheese particles;

[0042] Step 5, the formed cheese particles are discharged from the mixing tank 32, and the cheese particles are placed in a porous cylinder for stacking and forming cheese slices;

[0043] Step 6, addi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com