Steaming and baking all-in-one machine

An all-in-one, steaming and roasting technology, which is applied to steam cooking utensils, roasters/barbecue grids, cooking utensils, etc., can solve the problems that affect the cooking effect, and the integrated steaming and roasting machine cannot achieve professional steaming and professional roasting. The effect of good cooking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

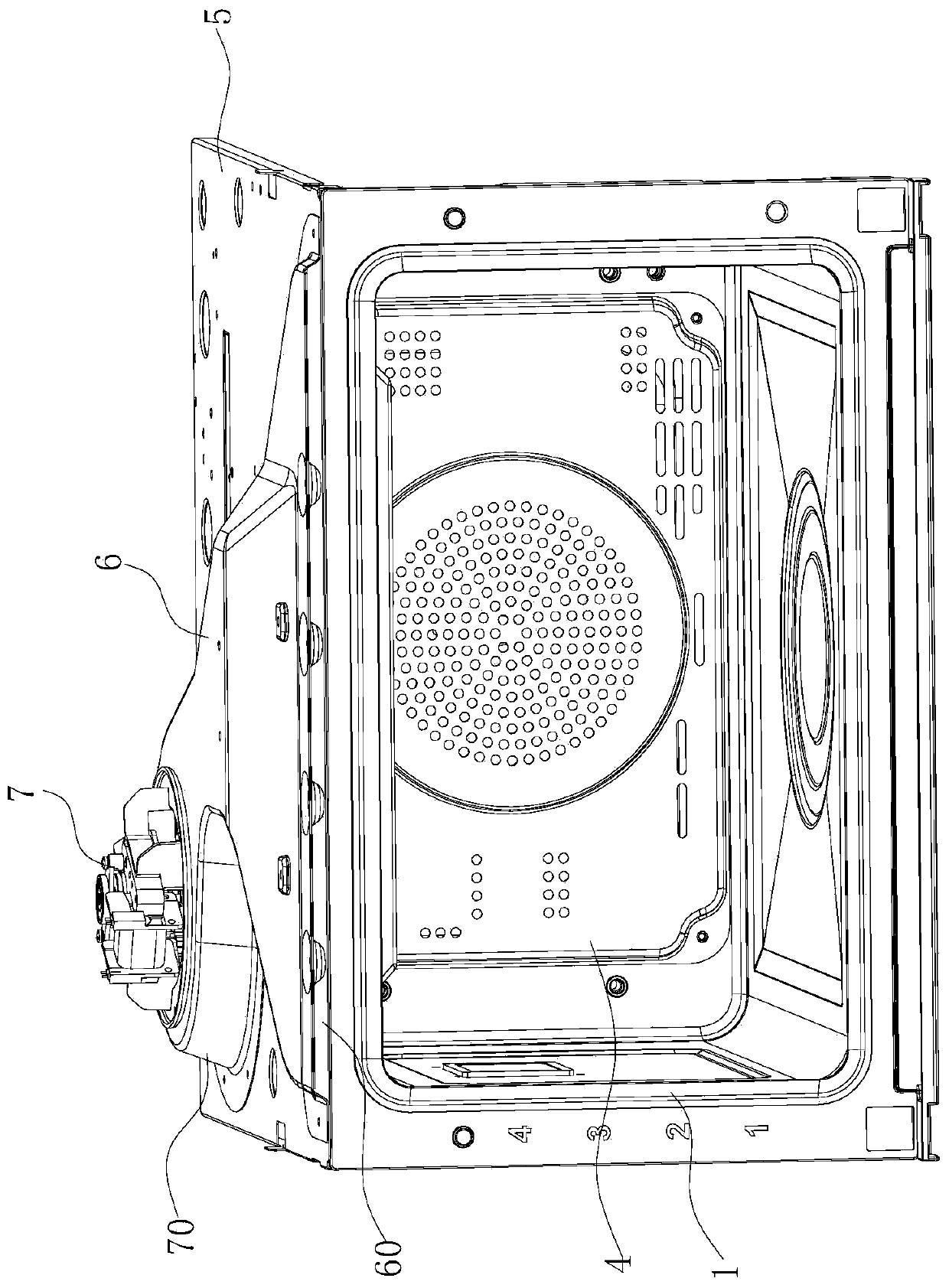

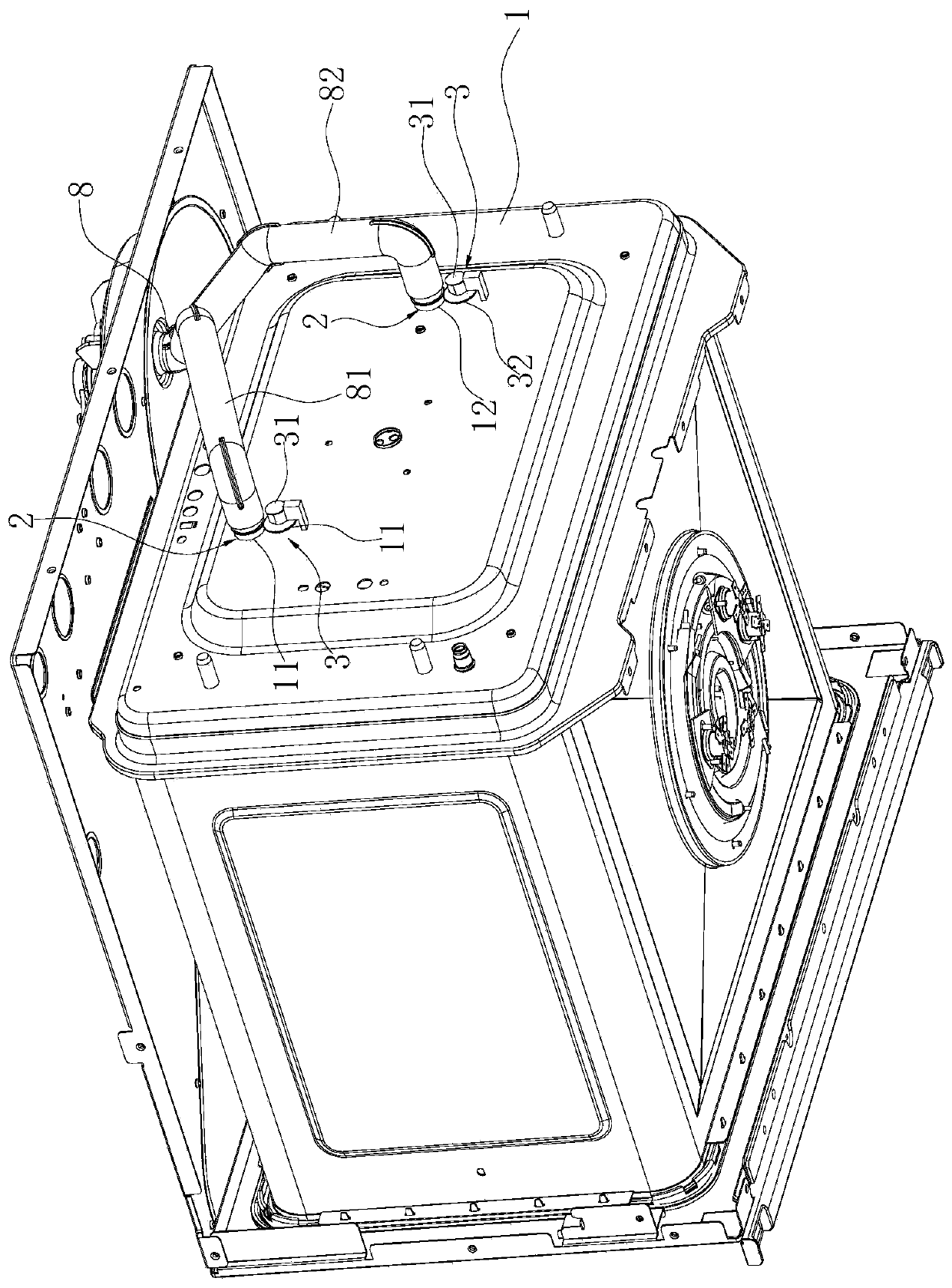

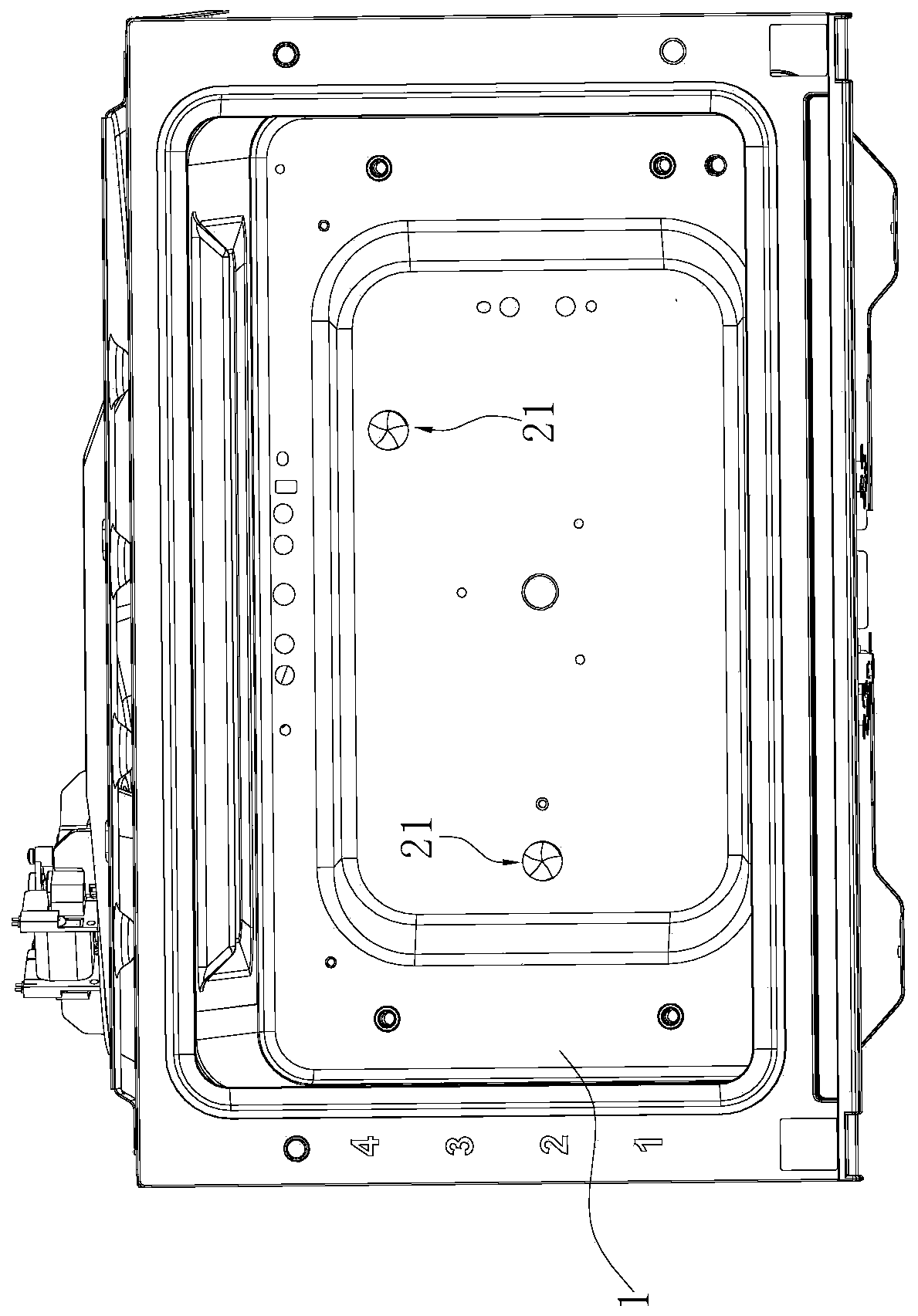

[0027] Such as Figure 1-11 As shown, a steaming and roasting integrated machine includes an inner container 1, a first exhaust port 11 and a second exhaust port 12 are respectively opened on the back plate of the inner container 1, and the height of the first exhaust port 11 is higher than The second exhaust port 12. A hot air baffle 4 is arranged on the back side of the inner tank 1, and the hot air baffle 4 and the back plate of the inner tank 1 enclose a hot air chamber, and the hot air chamber is respectively provided with a hot air blower and a back heating tube surrounding the outer periphery of the hot air blower. (In this embodiment, neither the hot air blower nor the back heating pipe is shown), the first exhaust port 11 and the second exhaust port 12 are both located in the hot air chamber. In the steaming mode, the steam entering...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com