Fire fighting device for large-people flow place and using method of fire fighting device

A fire-fighting device and place technology, which is applied in the field of fire-fighting devices in places with large crowds, can solve the problems of limited range of action of fire extinguishers and burns of users, and achieve the effect of preventing people from being burned and slowing down the moving speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

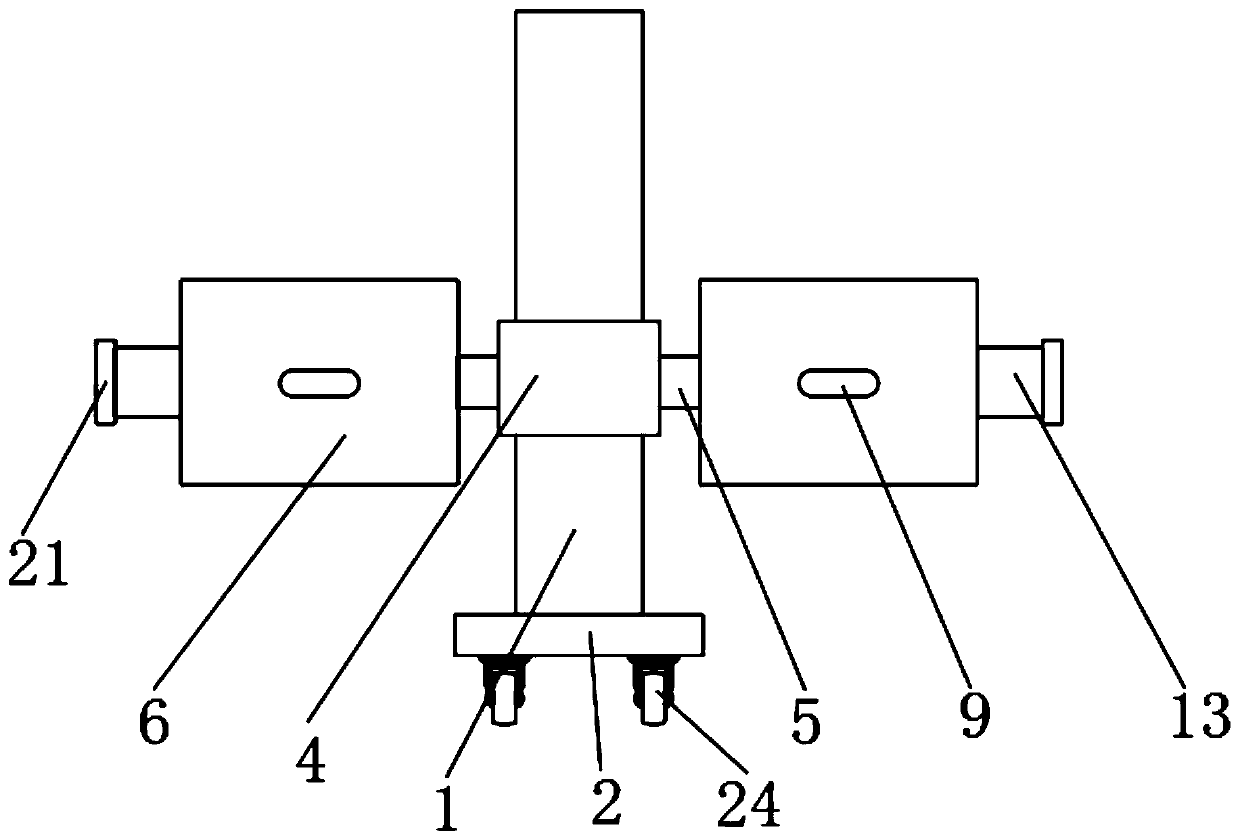

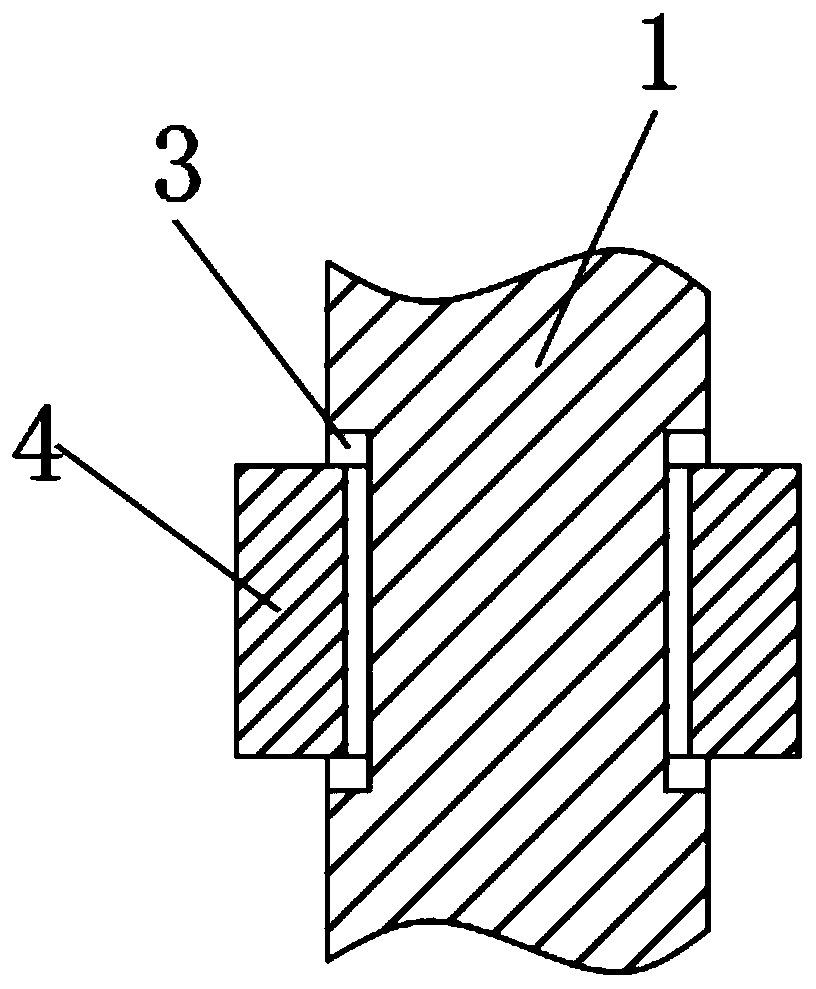

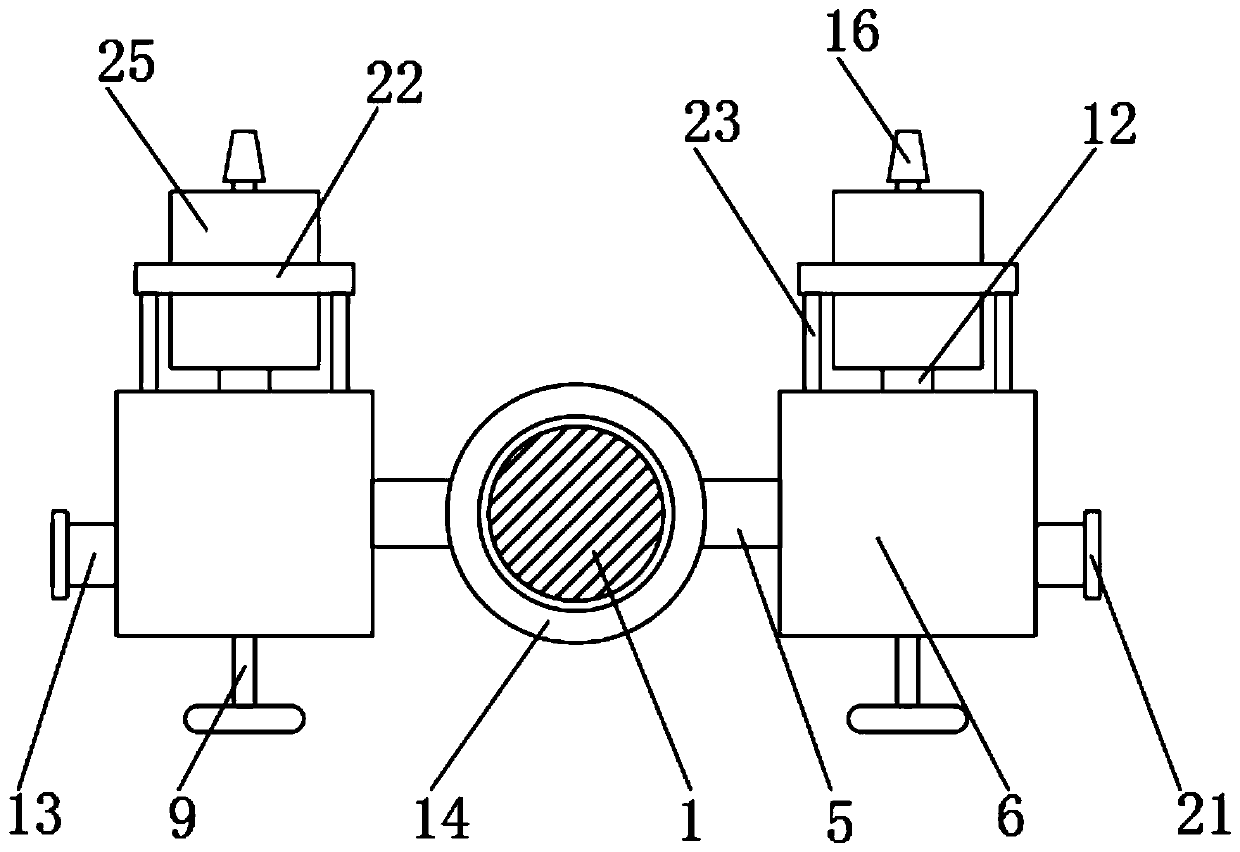

[0047] see Figure 1-4 , a kind of fire-fighting device that is used for large crowd flow place, comprises support column 1, and the bottom end of support column 1 is fixedly installed with fixed base 2, and the bottom of fixed base 2 is fixedly connected with universal wheel 24, and universal wheel 24 is provided with There is a brake mechanism, so that the fire-fighting device is convenient to move to the vicinity of the fire source, and can be fixed by the brake mechanism on the universal wheel. The outer wall of the support column 1 is provided with an annular rotation groove 3, and the outer wall of the support column 1 is located in the same position as the A rotating ring 4 is installed in the rotating groove 3, and a support rod 5 is fixedly installed on the outer walls of the left and right sides of the rotating ring 4. The end of the supporting rod 5 away from the rotating ring 4 is fixedly installed with a device box 6, and the internal activities of the device case ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com