Inclined vertical type ring rolling machine

A coiler and slope technology, applied in metal processing equipment, feeding devices, manufacturing tools, etc., can solve problems such as hindering automatic or semi-automatic production, labor-intensive labor, and inability to achieve self-flow, etc., and achieve simple design and operation. Simple, diameter-reducing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below in conjunction with accompanying drawing:

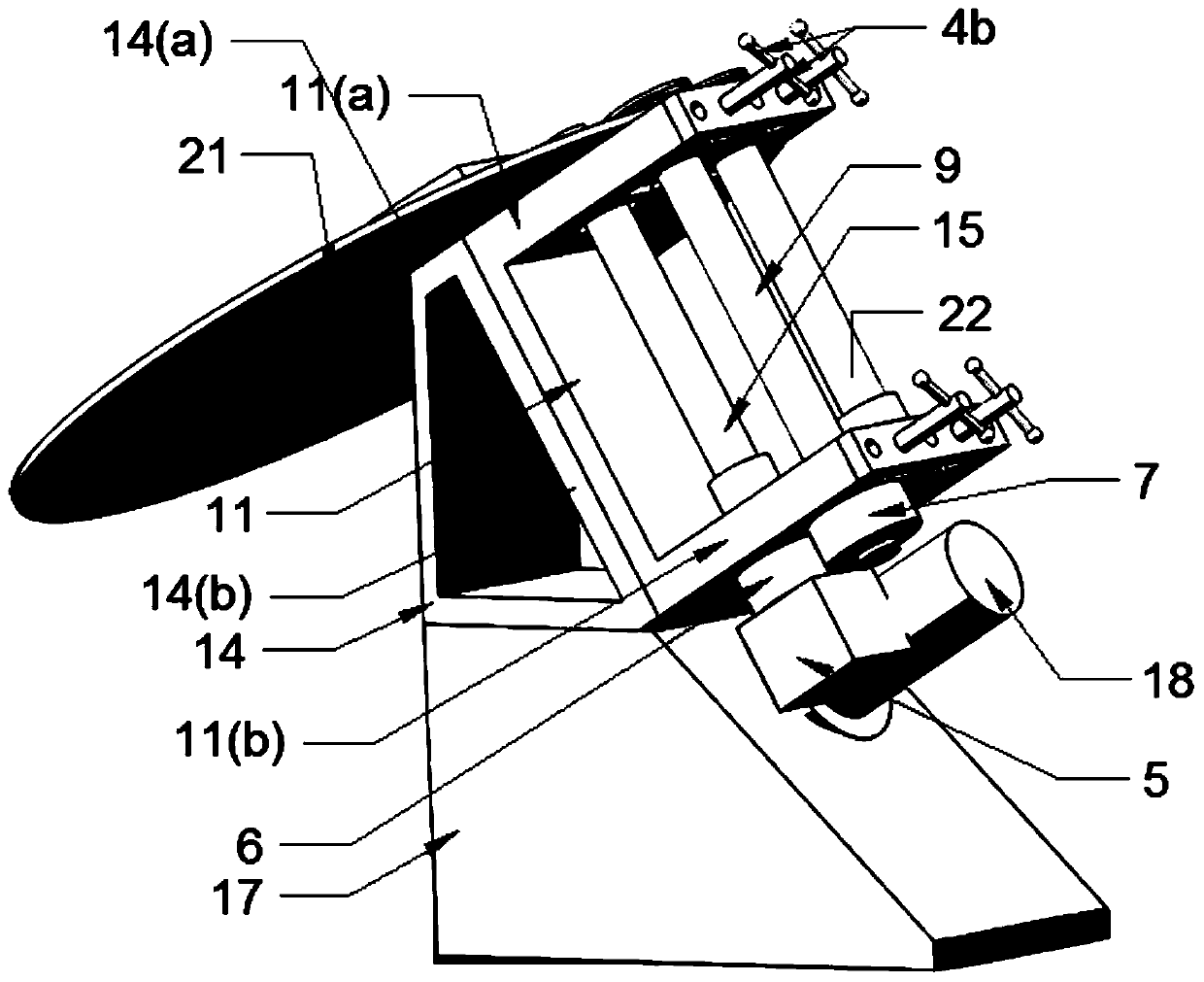

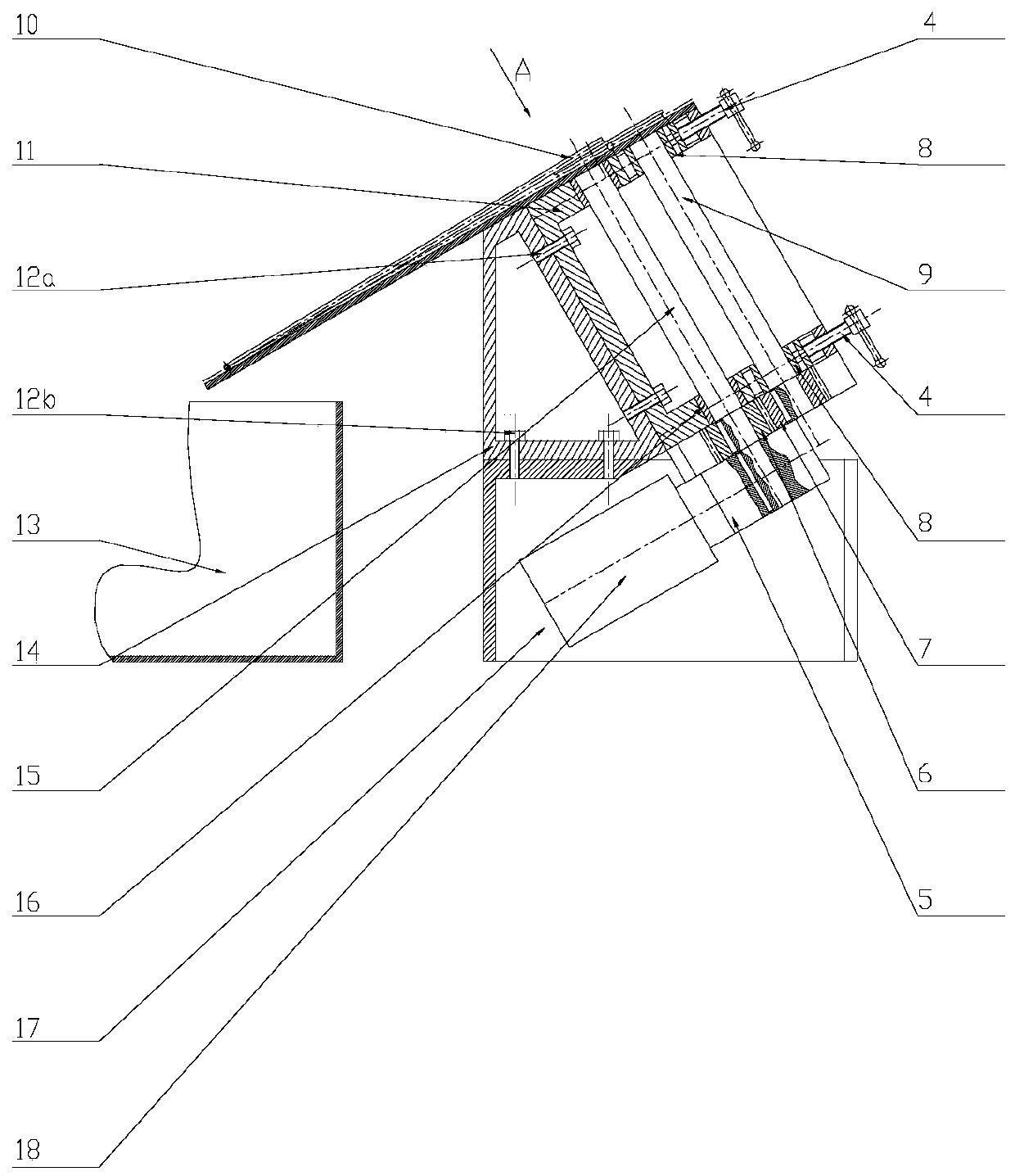

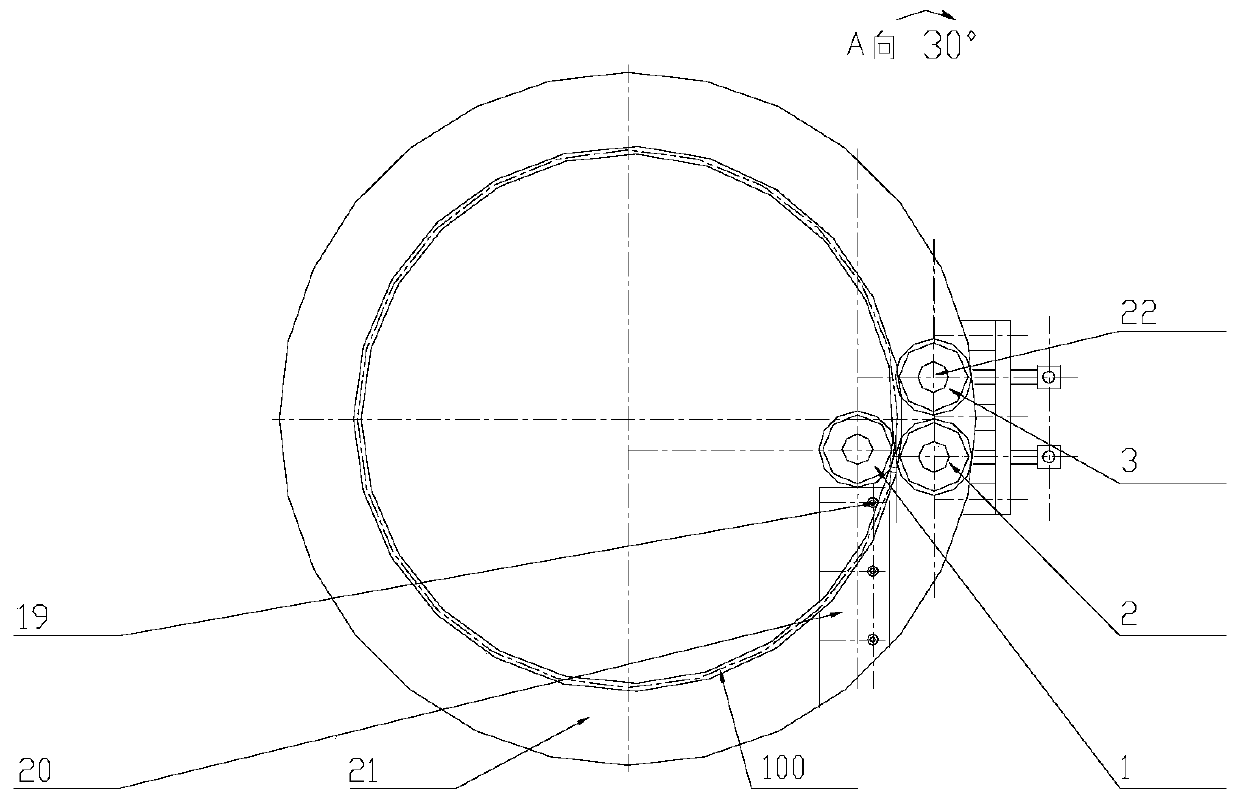

[0018] Such as figure 1 , figure 2 and image 3 As shown, an inclined vertical coiler includes: a support assembly, a working table 21 , a power assembly and a product collection box 13 . The support assembly includes a base 17 and a quadrilateral inclined platform frame 14 , the base 17 is in the shape of a trapezoid, and the inclined platform frame 14 is arranged on the top surface of the base 17 . Such as Figure 4 As shown, the inclined platform frame 14 is in the shape of a trapezoid stretched upward at the upper right corner, the bottom edge is fixedly connected with the top surface of the base 17, the left side is aligned with the left side of the base 17, and the upper right corner forms a first inclined plane 14 (a) and a second inclined plane 14(b), and the first slope 14(a) and the second slope 14(b) are at right angles. The working platform 21 is installed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com