Multifunctional spare and accessory part assembling table for automobile repair machining

A kind of spare parts and multi-functional technology, applied in the field of multi-functional auto repair processing spare parts assembly table, can solve the problem of reducing the practicability of automobile processing spare parts assembly table, the clamping tool does not have the clamping direction exchange, and there is no workpiece clamp To achieve the effect of convenient and quick angle adjustment, compact structure and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The specific implementation manner of the present invention will be described below in conjunction with the accompanying drawings.

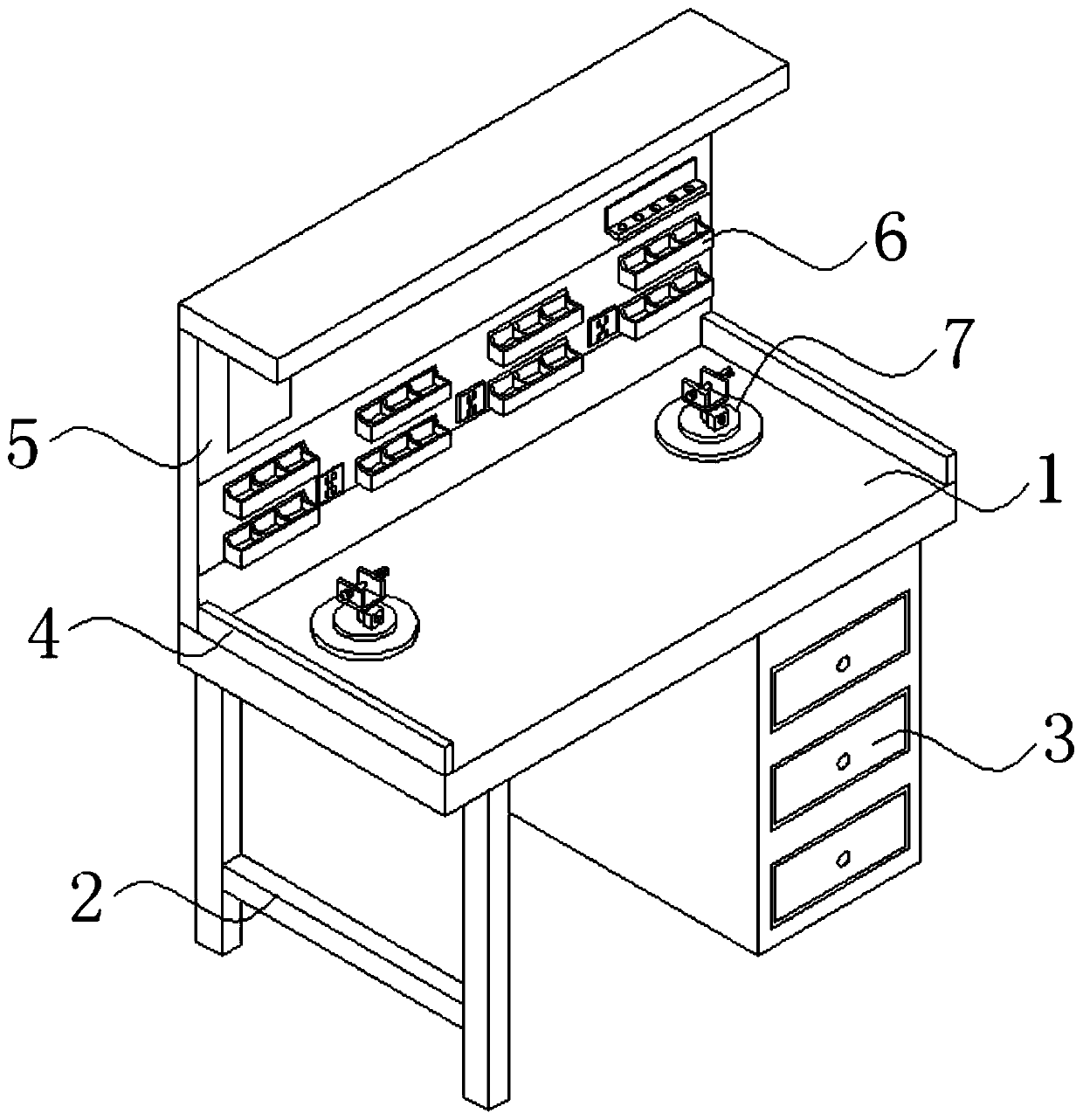

[0040] Such as Figure 1-Figure 8 As shown, the multifunctional auto repair processing spare parts assembly platform of this embodiment includes a horizontally placed workbench 1, one end of the bottom surface of the workbench 1 is supported by a support frame 2, and the other end of the bottom surface of the workbench 1 is supported by a storage box 3, The two ends of the upper surface of the workbench 1 are respectively equipped with baffles 4 perpendicular to the workbench 1, the rear end of the upper surface of the workbench 1 is installed with a vertical plate 5 perpendicular to the workbench 1, and a plurality of storage boxes 6 are installed on the vertical plate 5 and sockets, and a plurality of clamping assemblies are installed at intervals on the upper surface of the workbench 1,

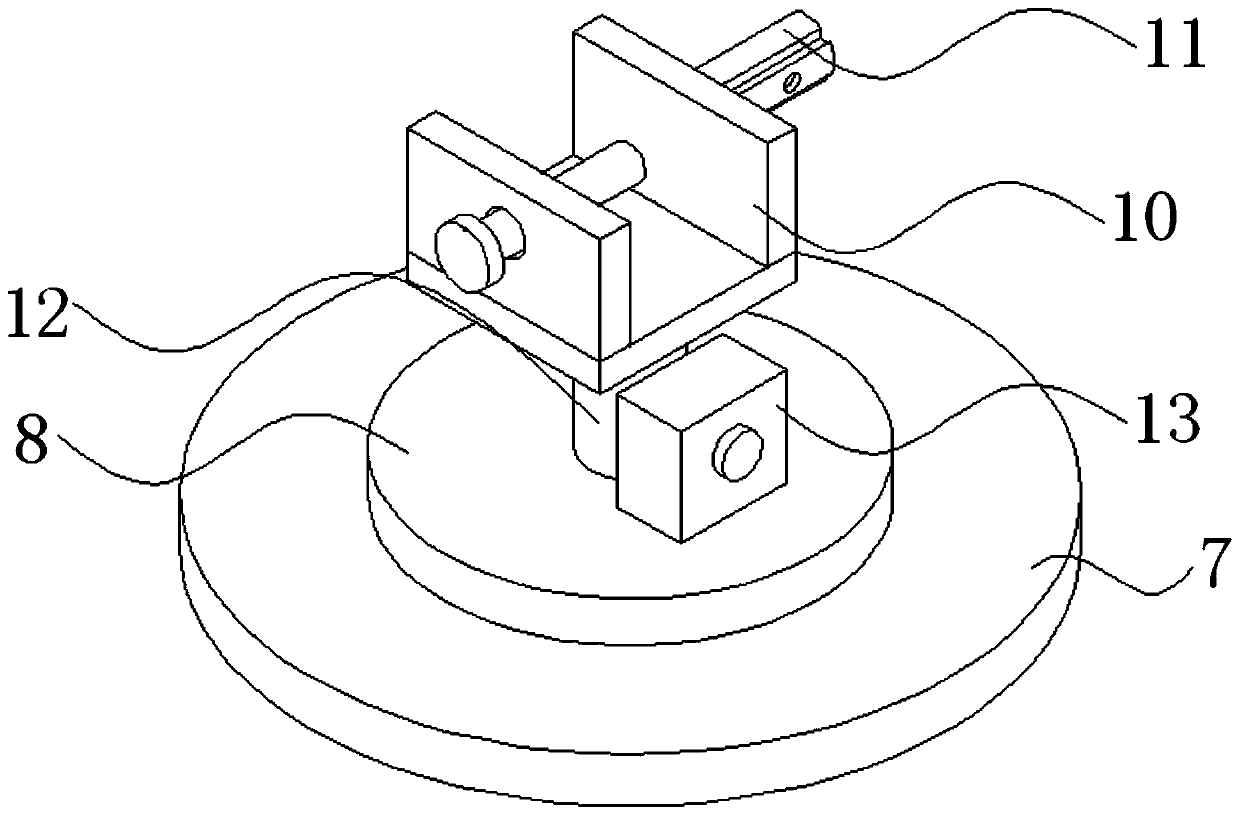

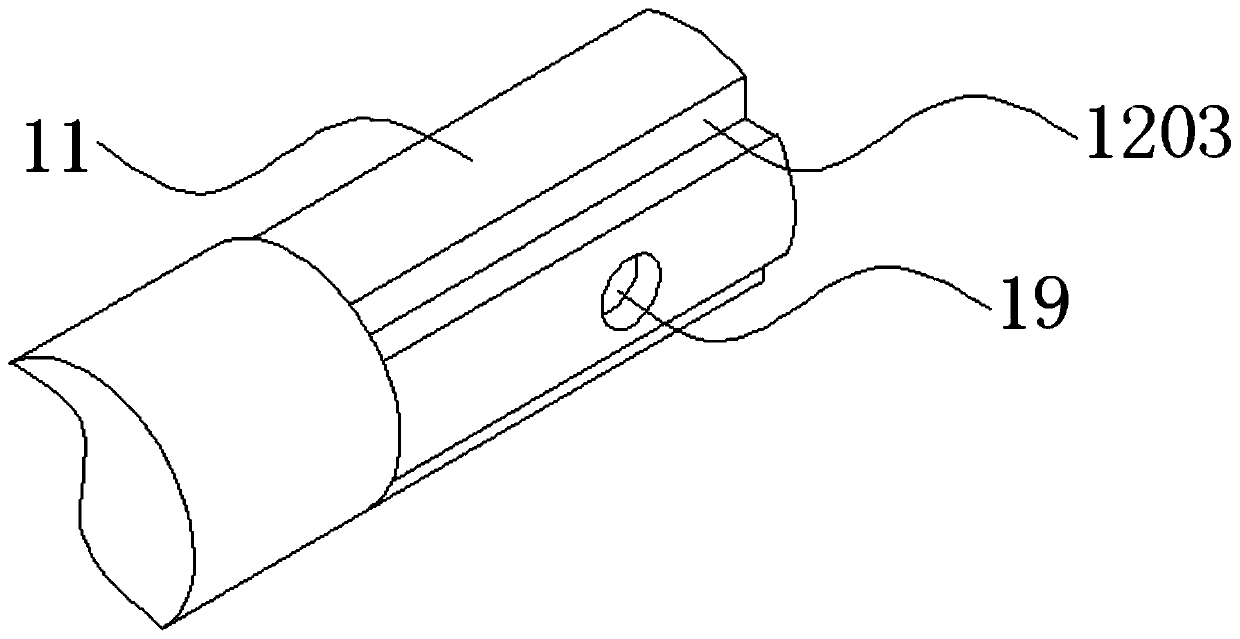

[0041] The structure of a single clamping assem...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com