Automatic device for uniformly sprinkling fermented grains to wine retort

An automatic and wine retort technology, applied in the field of winemaking, can solve the problems of short service life and complicated swinging mechanism of the dustpan, and achieve the effects of long service life, small equipment wear and improved contact area.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

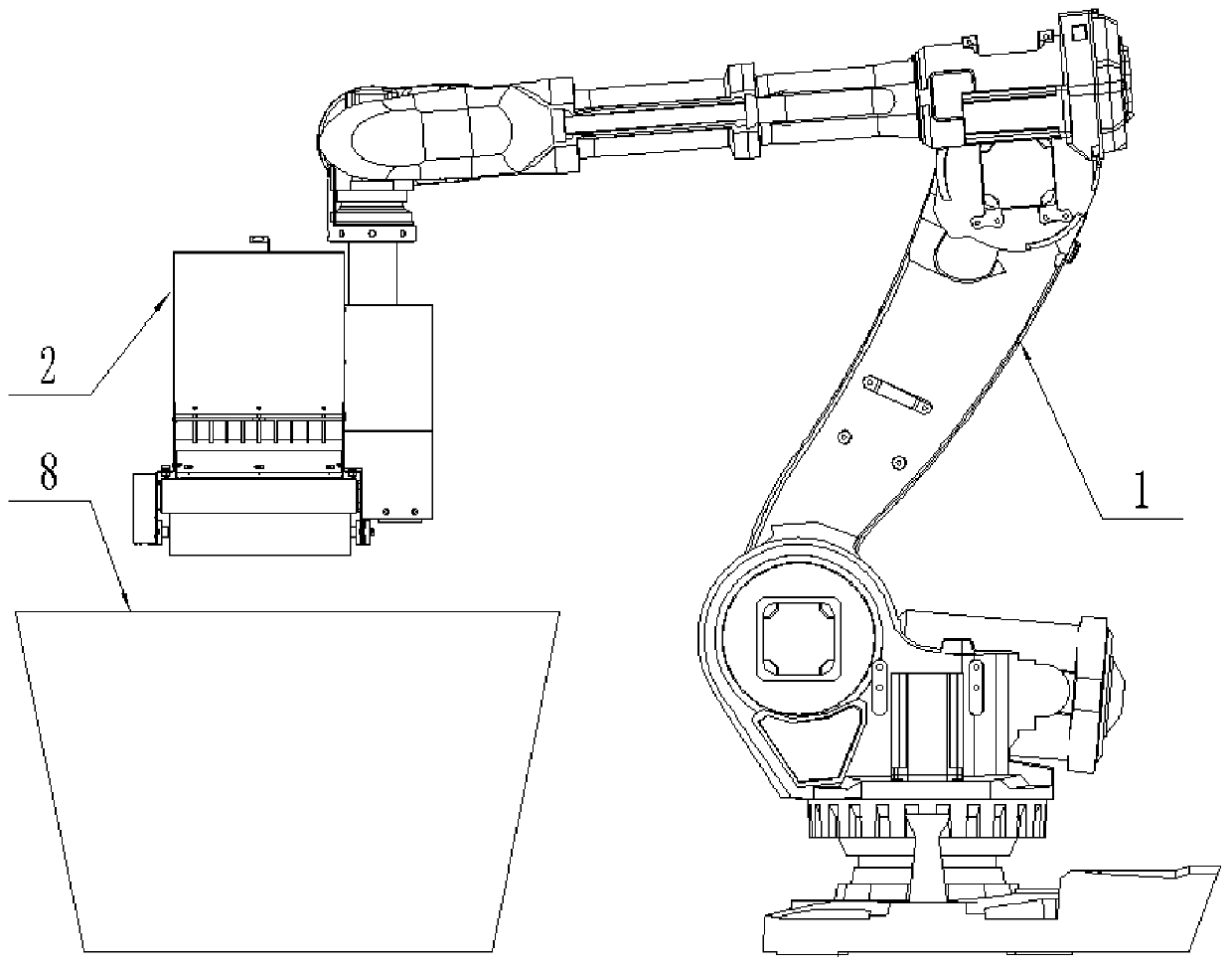

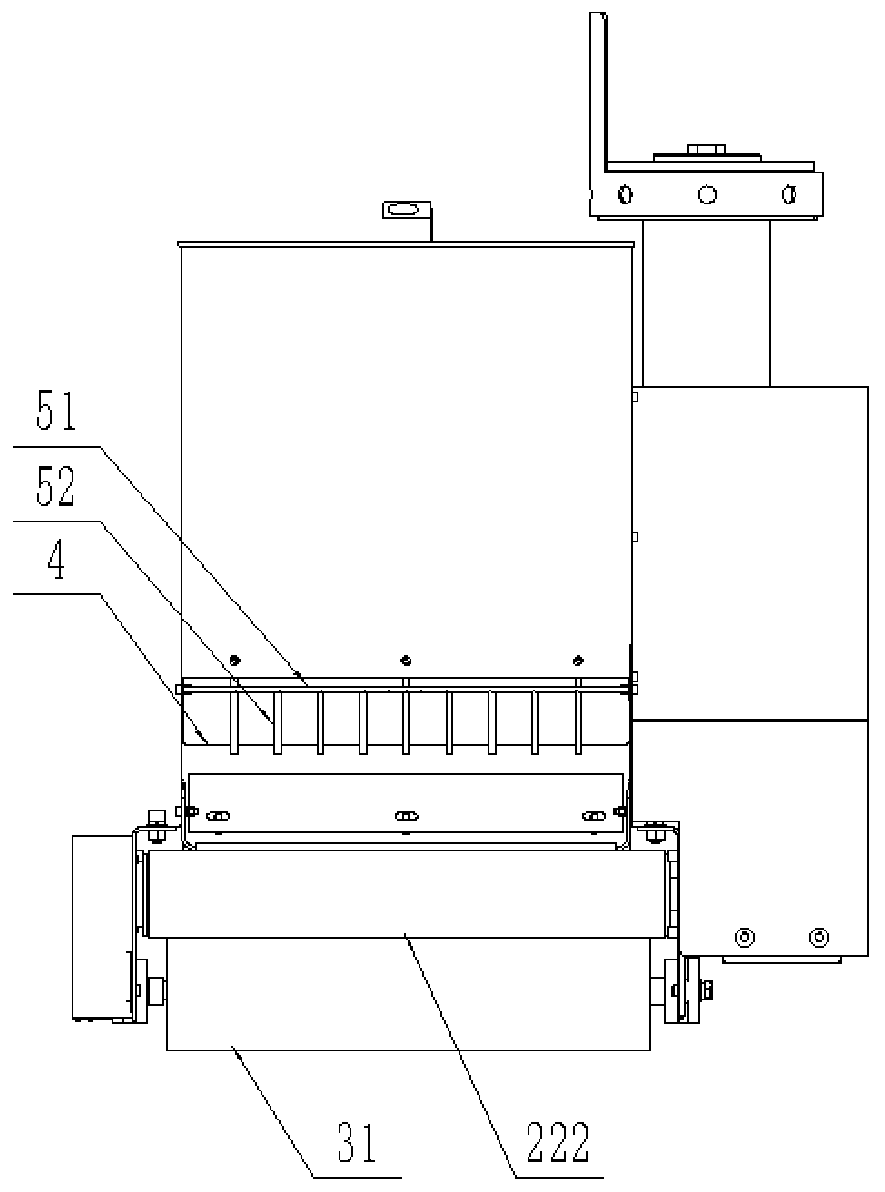

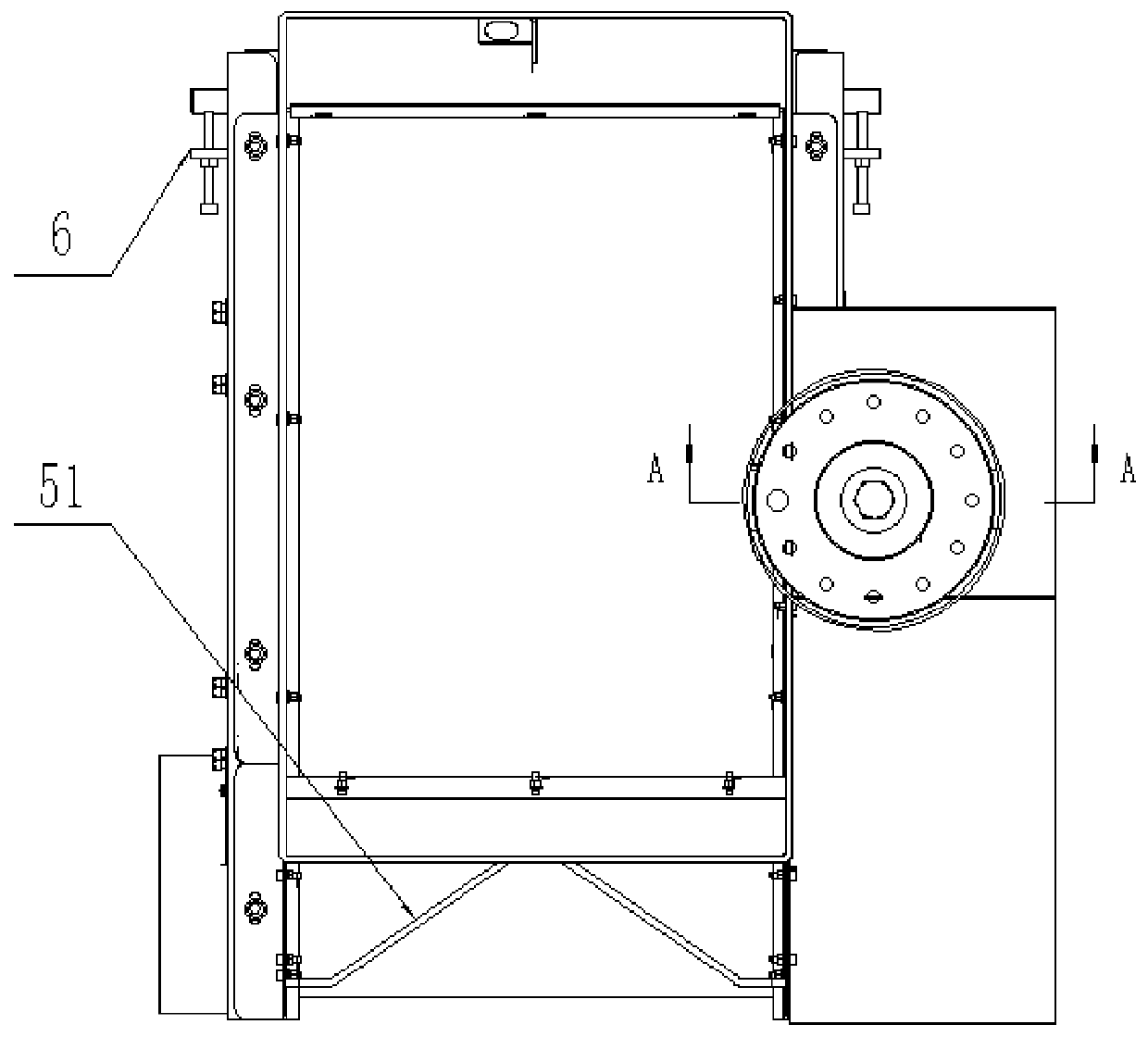

[0034] Such as Figure 1 to Figure 10 As shown, the automatic retort device of the present invention includes a robot 1, an upper retort dustpan 2 connected to the robot 1, and a wine retort 8. The upper retort dustpan 2 includes a hopper 21 and a conveyor arranged below the hopper 21; the conveyor includes Belt 221, driving roller 222, driven roller 223 and motor reducer 224 connected with driving roller 222; a cleaning mechanism is arranged below driving roller 222, and cleaning mechanism includes hairbrush roller 31 and the hairbrush arranged on the surface of hairbrush roller 31 A first sprocket 2221 is arranged at the end of the driving roller 222 , a second sprocket 311 is arranged at the end of the brush roller 31 , and the second sprocket 311 is connected with the first sprocket 2221 through a chain 312 . The hopper 21 is provided with an ultrasonic sensor (not shown in the figure) for measuring the height of the fermented grains in the hopper. The conveyor is provide...

Embodiment 2

[0039] Such as Figure 4 As shown, this embodiment is a further improvement made on the basis of Embodiment 1. It also includes an adjustment mechanism for adjusting the height of the fermented grains on the belt; the adjustment mechanism includes an adjustment plate 4 arranged on the hopper 21 and perpendicular to the belt 221, the adjustment plate 4 is provided with a long hole, the adjustment plate 4 can be relatively The hopper 21 moves vertically, and the adjusting plate 4 is connected with the hopper 21 through bolts.

[0040] Working principle: By moving the adjustment plate 4 in the vertical direction, the distance between the adjustment plate 4 and the belt 221 can be adjusted, thereby controlling the thickness of the fermented grains on the belt. Corresponding adjustments can be made according to different processes or working conditions to make the grains It meets the requirements of different retort process and has strong versatility.

Embodiment 3

[0042] Such as figure 2 with image 3 As shown, this embodiment is a further improvement made on the basis of Embodiment 1. It also includes a material distribution mechanism for breaking up the unstrained spirits on the belt; the material distribution mechanism includes a material distribution pipe 51 arranged at one end of the conveyor outlet, and the lower part of the material distribution pipe 51 is connected with a material distribution pipe 51 perpendicular to the belt 221. Nail 52 ; the distributing pipe 51 is arranged in a tapered shape, and the width of the tapered part of the distributing pipe gradually increases in the direction away from the hopper 21 .

[0043] Working principle: Because the fermented grains are relatively sticky, the distributing nail can break up the glutinous grains that are knotted on the belt; at the same time, due to the viscosity of the fermented grains, when the fermented grains fall from the hopper to the belt, there will be thick, In ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap