Parallel high-power power supply

A high-power power supply, parallel-connected technology, applied in the direction of output power conversion device, DC power input conversion to DC power output, electrical components, etc., to achieve equipment damage protection, reduce power output, and make up for the inability to protect the subsequent power consumption The effect of device security

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

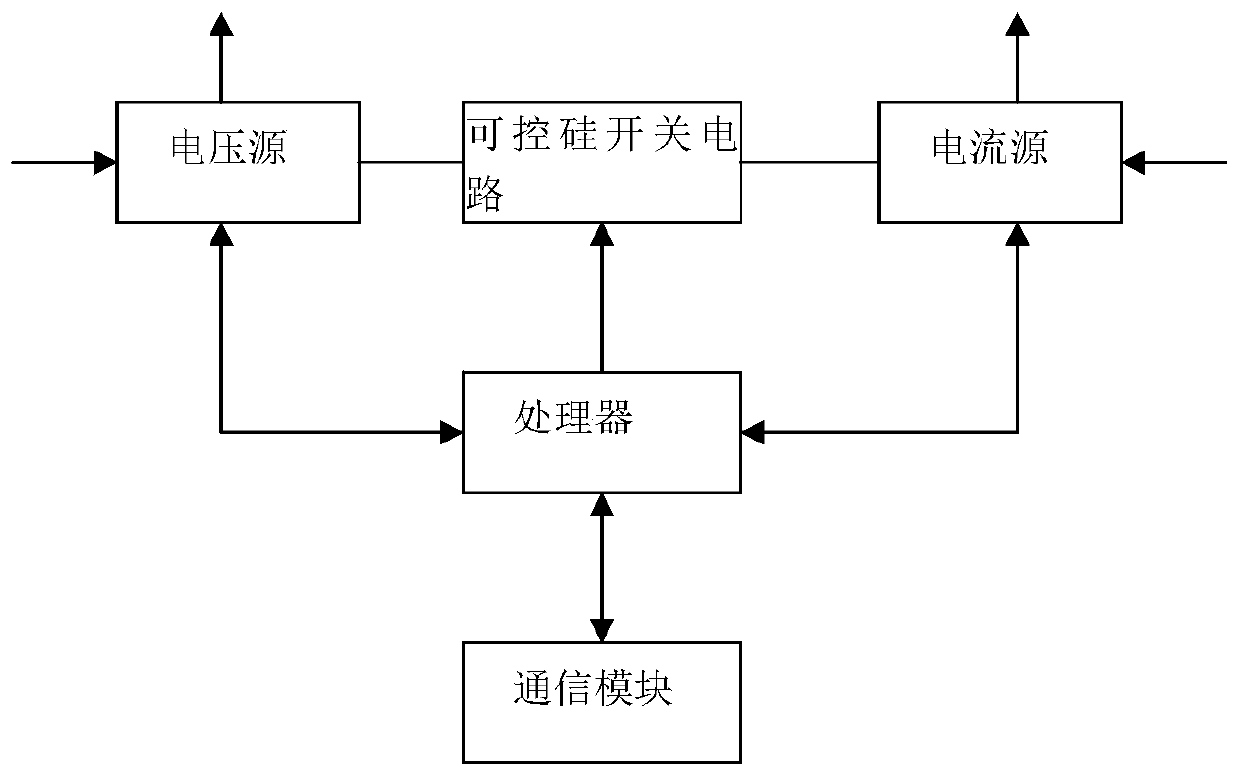

[0024] Embodiment 1: as figure 1 , image 3 , Figure 4 , image 3 , Figure 6 , Figure 7 , Figure 8 As shown, this embodiment provides a parallel high-power power supply, including one voltage source and one current source connected in parallel. The control terminals of the voltage source and the current source are connected to the processor at the same time, and receive control signals from the processor. Specifically, the voltage is derived from the processor receiving a reference DA voltage and outputting a specified voltage based on the reference DA voltage. The output ends of the voltage source and the current source are simultaneously connected to both ends of the thyristor switch circuit.

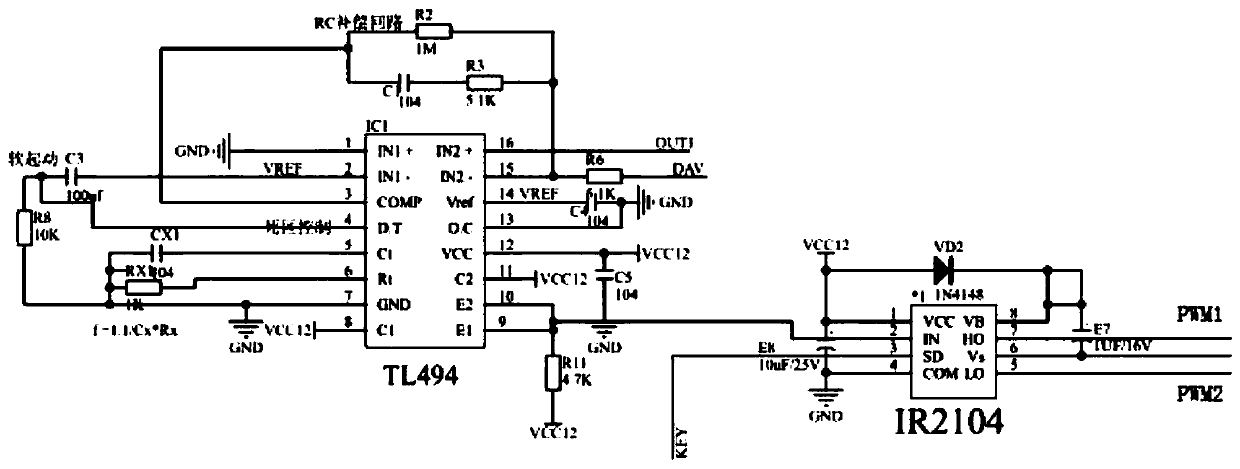

[0025] Such as image 3 , Figure 4 As shown, the voltage source adopts the BUCK synchronous step-down architecture, including a switching power supply controller, the switching power supply controller outputs PWM waves to the half-bridge driver according to the processor...

Embodiment 2

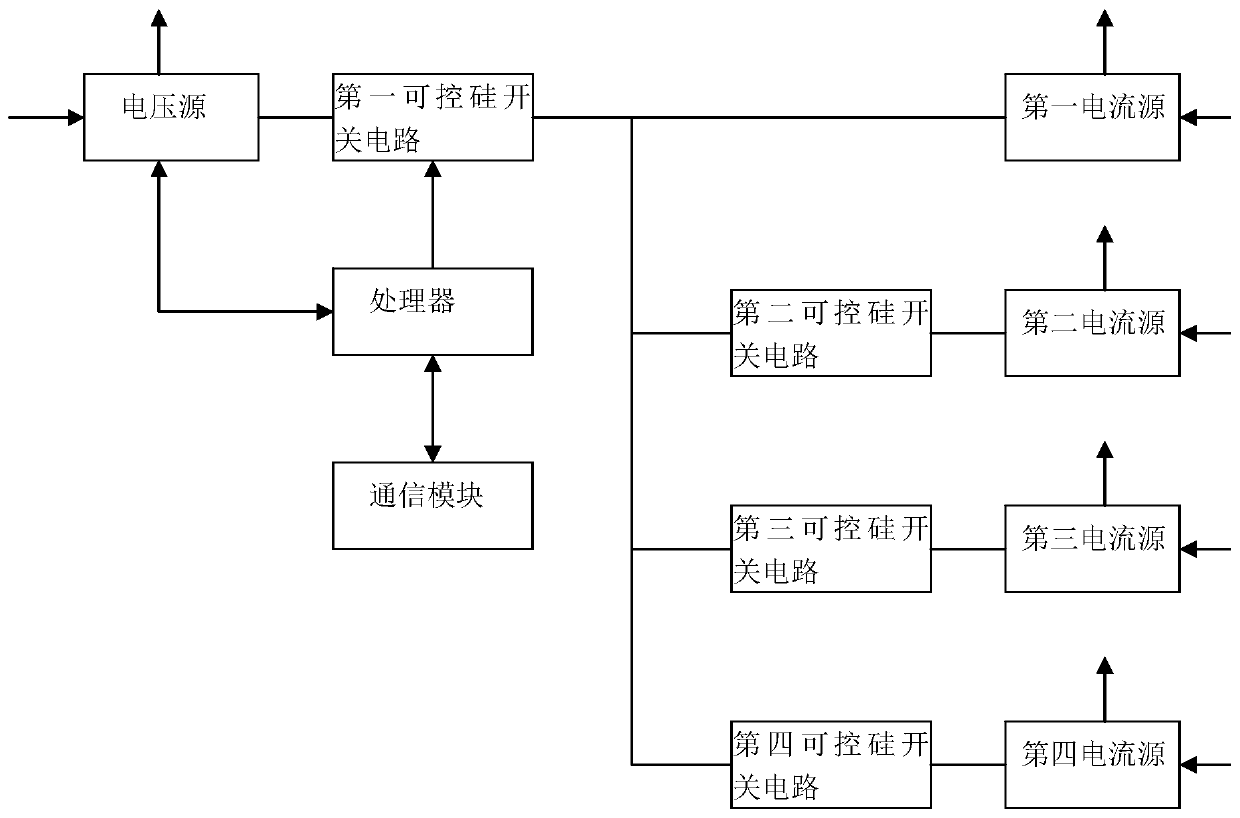

[0030] Embodiment 2: as figure 2 As shown, the difference from Embodiment 1 is that the parallel high-power power supply provided by this embodiment includes one voltage source connected in parallel and four current sources (the first current source, the second current source, the second Three current sources, the fourth current source), the control terminals of the voltage source and the four current sources are connected to the processor, and receive control signals from the processor. The voltage source is connected to the positive terminal of the one-way thyristor unit in the first thyristor switch circuit, and the output terminal of the first current source is connected to the negative terminal of the one-way thyristor unit in the first thyristor switch circuit; meanwhile, the first The second current source, the third current source, and the fourth current source pass through the second thyristor switch circuit, the third thyristor switch circuit, the fourth thyristor s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com