Self-cleaning revolving door

A revolving door and self-cleaning technology, which is applied in the field of revolving doors, can solve the problems that the revolving door cannot stop running during the day, the operation is inconvenient, and the aesthetics of the revolving door is affected.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

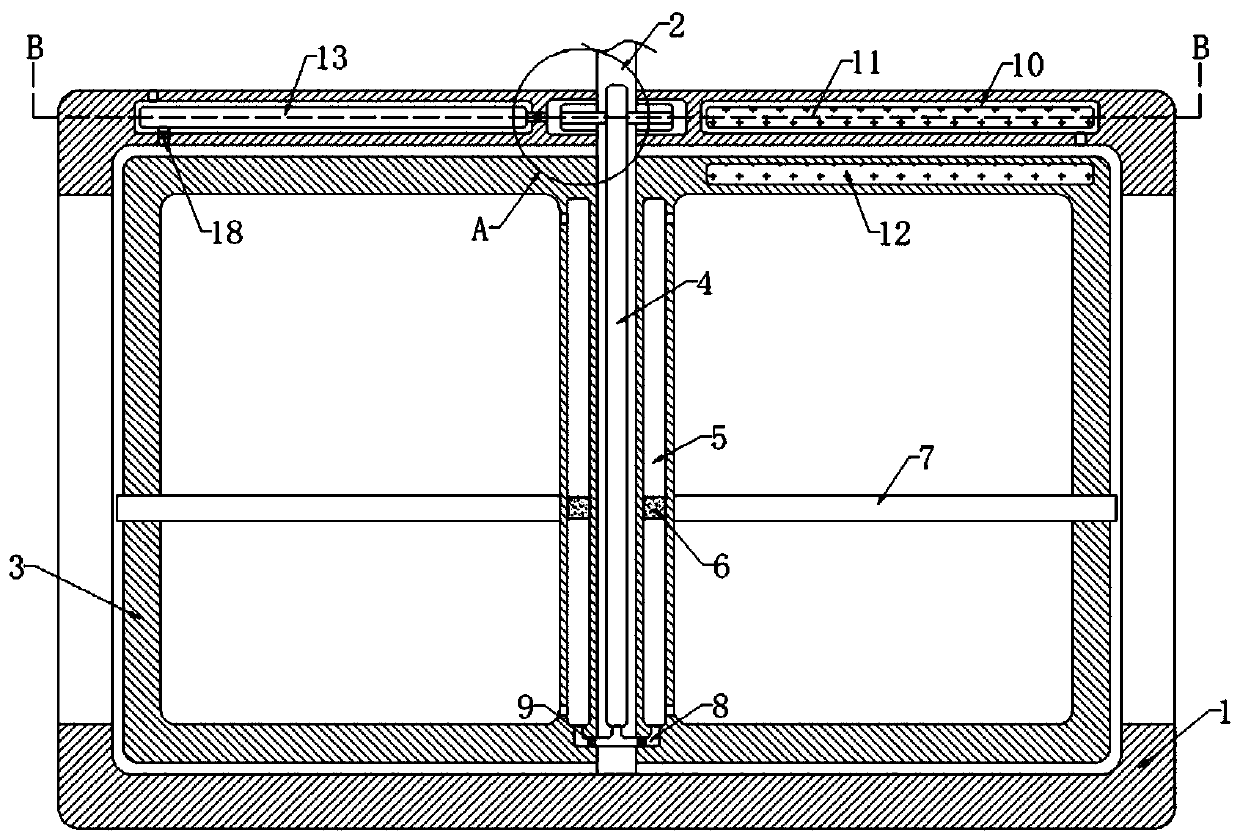

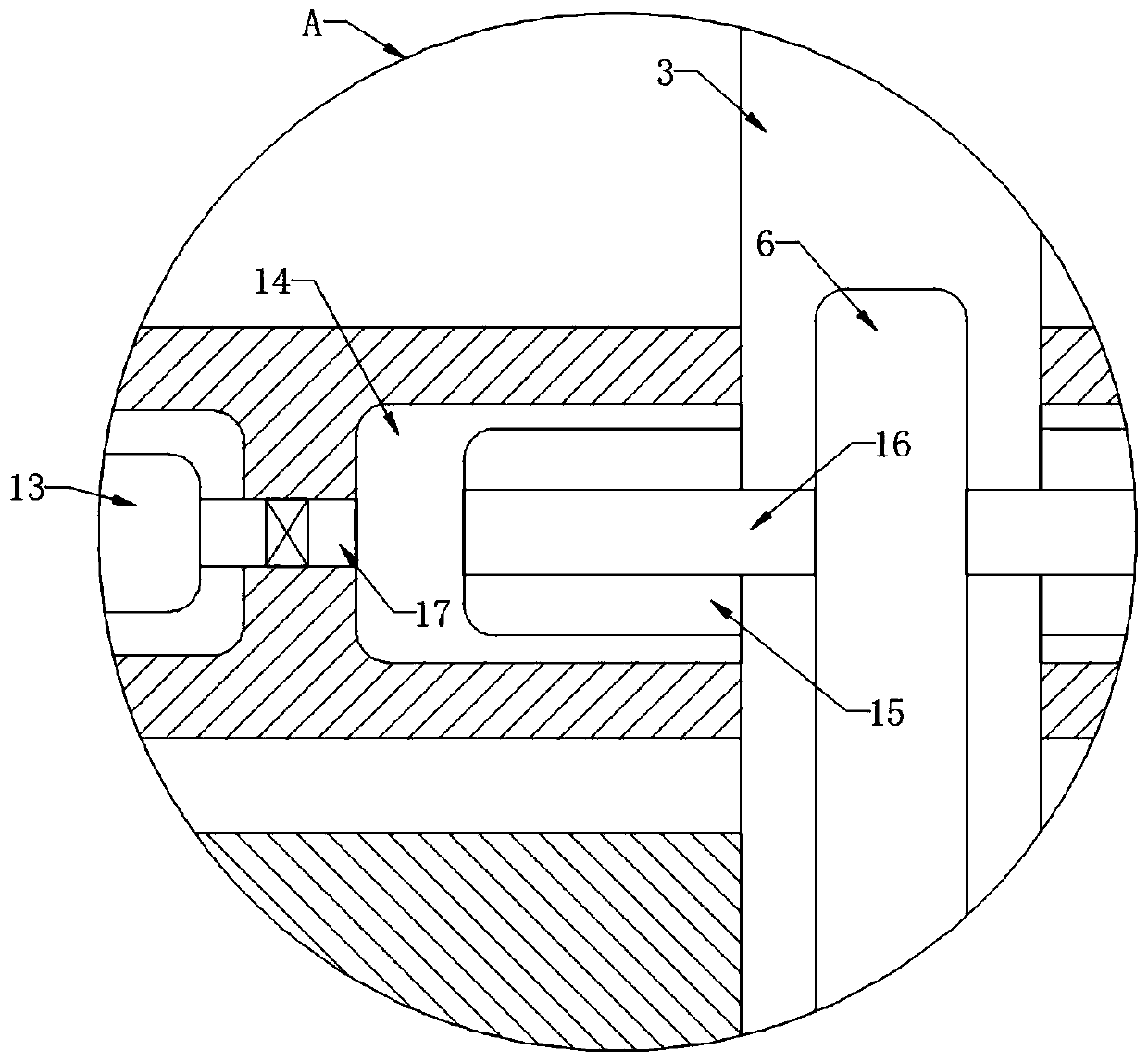

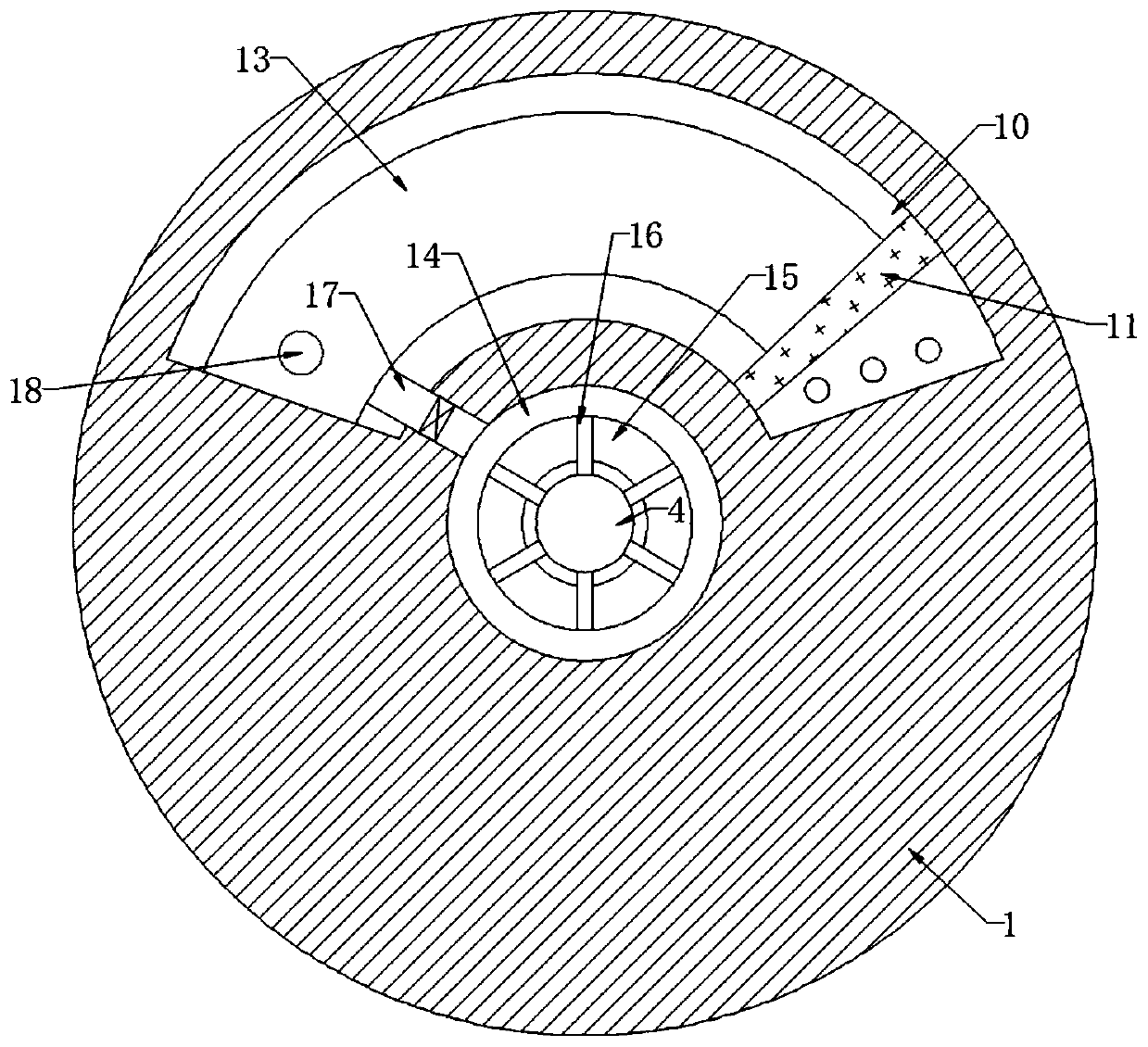

[0024] refer to Figure 1-3 , a self-cleaning revolving door, comprising a cylindrical door frame 1, the inner wall of the cylindrical door frame 1 is rotatably connected with a rotating shaft 2, and the rotating shaft 2 is driven by an external drive motor, which is the prior art, and the side walls of the rotating shaft 2 are evenly distributed and fixedly connected to a plurality of Revolving door frame 3, the inner wall of cylindrical door frame 1 and revolving door frame 3 is fixedly connected with glass, the inner wall of rotating shaft 2 is provided with cavity 4, and the side wall of revolving door frame 3 close to rotating shaft 2 is provided with sliding plug chamber 5, the inner wall of sliding plug chamber 5 is below A small hole communicating with the outside world is provided, and the inner wall of the sliding plug chamber 5 is slidably connected with a magnetic sliding plug 6. Further, a through hole communicating with the outside world is provided above the inne...

Embodiment 2

[0031] refer to Figure 4 The difference from Embodiment 1 is that a water storage chamber 19 is provided on the side wall of the revolving door frame 3 away from the rotating shaft 2, and the inner bottom of the water storage chamber 19 is elastically connected with a slide plate 20 through a spring 21. Further, the inner wall of the water storage chamber 19 is connected with a The water inlet pipe is convenient to add cleaning liquid to the water storage chamber 19. Further, when the water in the water storage chamber 19 is used every time, the spring 21 can push the slide plate 20 to move upward, so that the water contacts the top of the liquid storage chamber 18 , and at this time the spring 21 and the water are kept in a balanced state, so that when gas enters, the water can be squeezed out at the first time, the inner bottom of the water storage chamber 19 communicates with the air outlet chamber 8 through the air inlet chamber 22, and the door frame 3 is rotated The upp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com