Wafer test probe station

A technology of wafer testing and testing probes, which is applied in the direction of measuring electricity, measuring devices, measuring electrical variables, etc., and can solve problems such as unsuitable wafer fixing and wafer fixing failure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

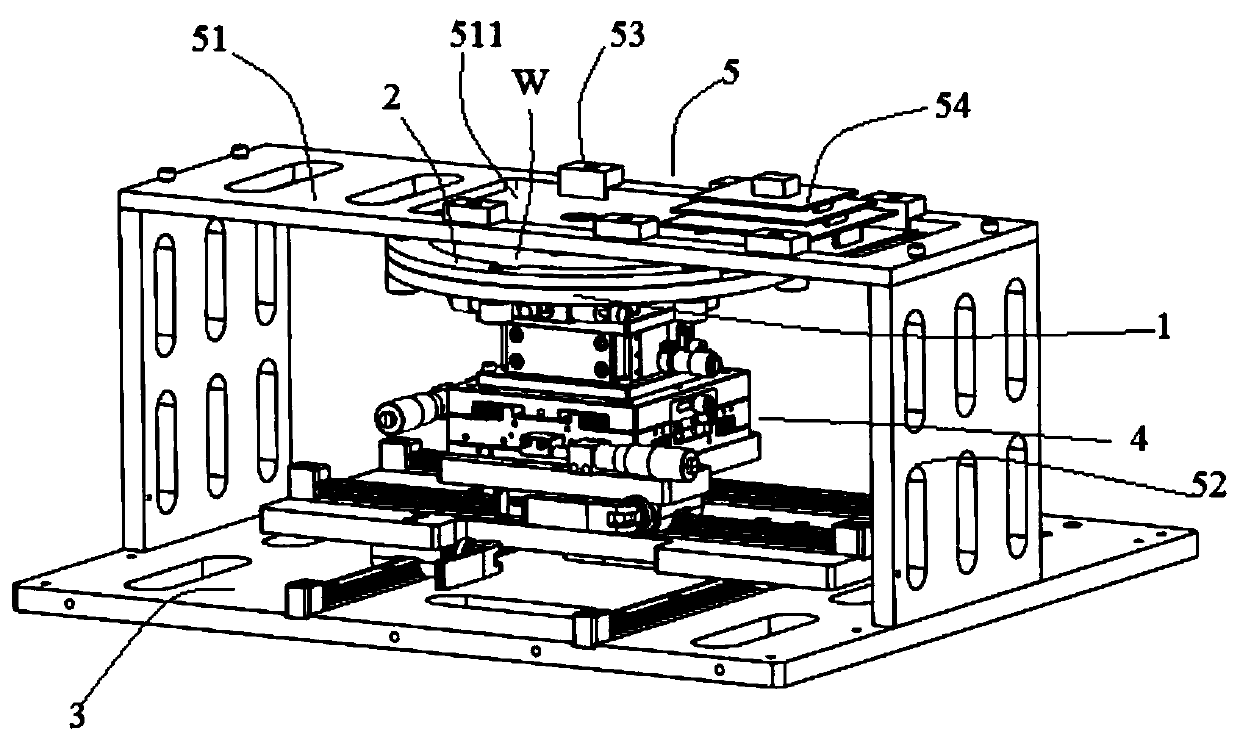

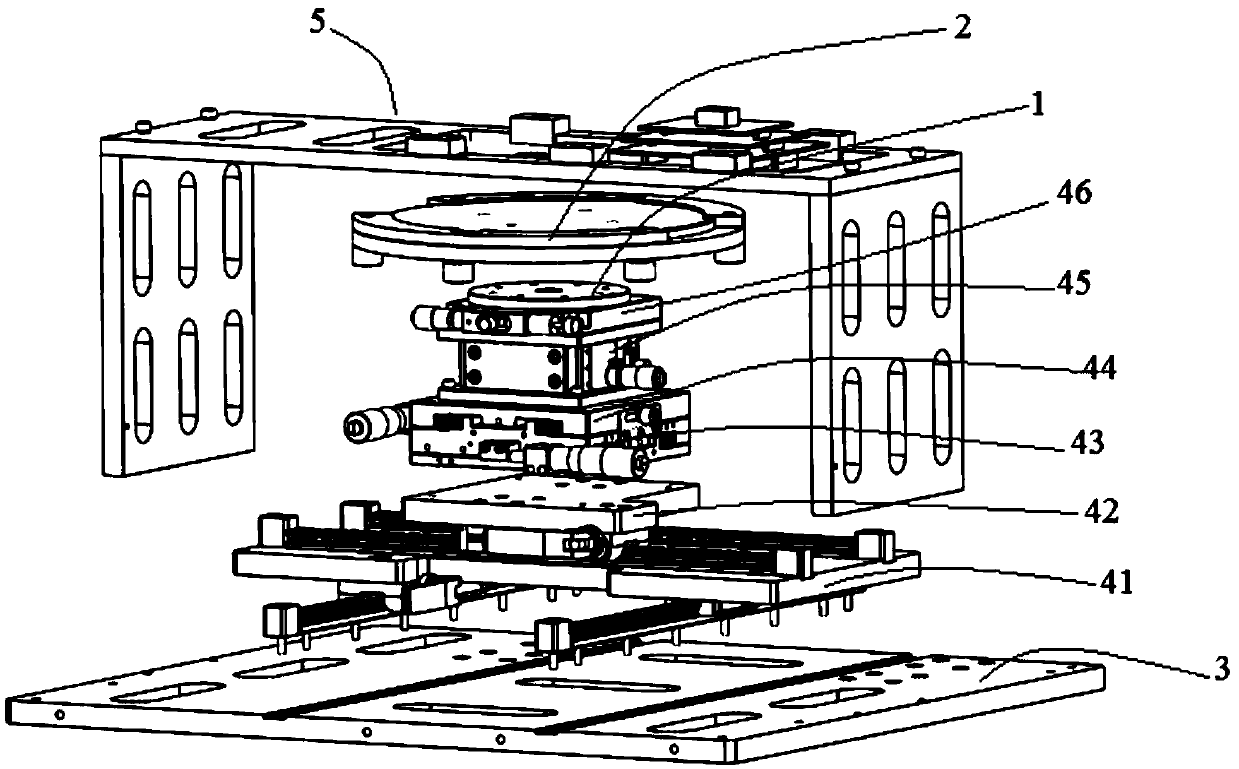

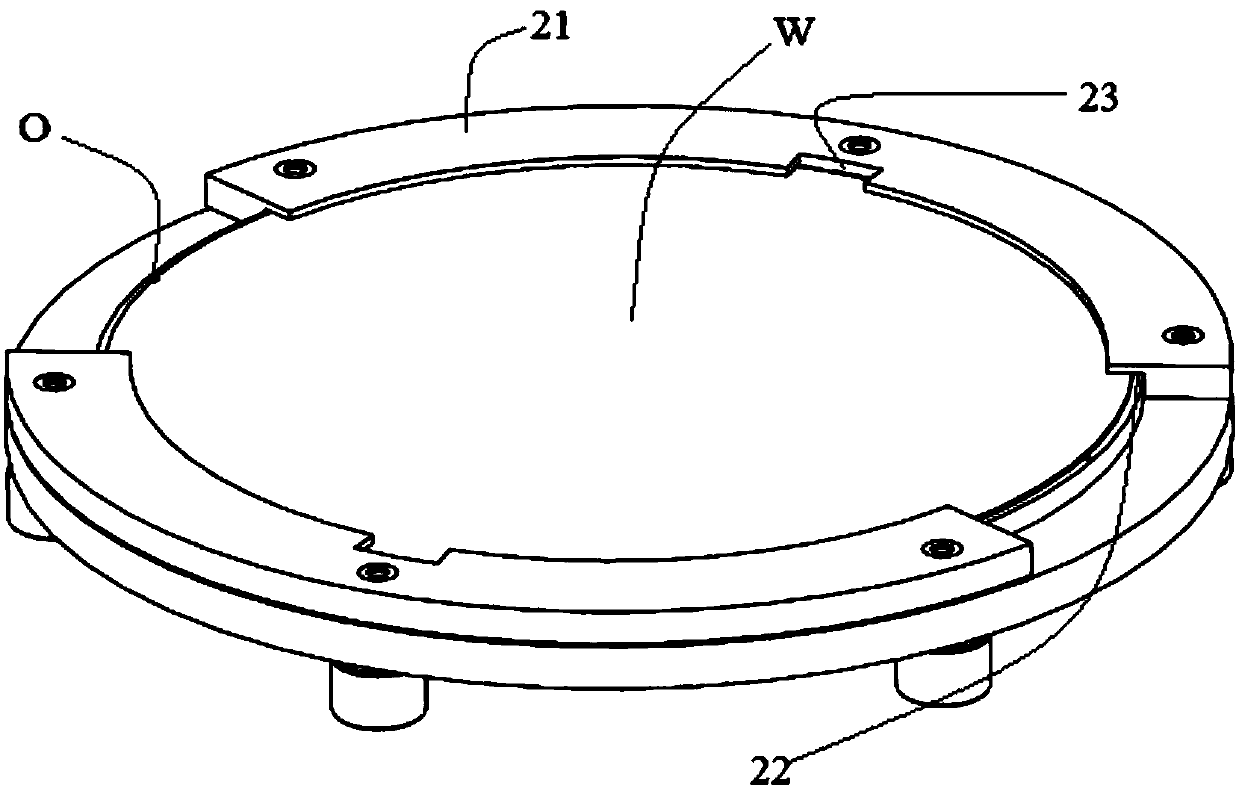

[0041] see Figure 1 to Figure 3 As shown, the embodiment of the present invention provides a wafer test probe station, which is mainly used in the performance test of semiconductors, optoelectronic components, integrated circuits, etc., especially for the test of wafers (wafer); wherein, the wafer Refers to the silicon wafer used in the production of silicon semiconductor integrated circuits. Because of its circular shape, it is called a wafer. The probe station includes a stage 1 on which a pressure ring 2 for fixing the wafer W is provided, and a structure corresponding to the outline of the wafer is provided on the pressure ring.

[0042] In this embodiment, the corresponding means that the outline is consistent, and the structure can be installed or fixed in cooperation with each other. For example, the outline of the wafer is circular. Features to match the wafer contour to hold the wafer in place.

[0043] In an embodiment of the present invention, a wafer test probe ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com