Multifunctional non-coded foot installation tooling

A multi-functional, installer's technology, applied in the direction of manufacturing tools, auxiliary devices, metal processing equipment, etc., can solve the problems that affect the quality and aesthetics of installation, low work efficiency, and single function of installation tooling, so as to save manpower and ensure Weld quality, effect of increasing versatility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and through specific implementation methods.

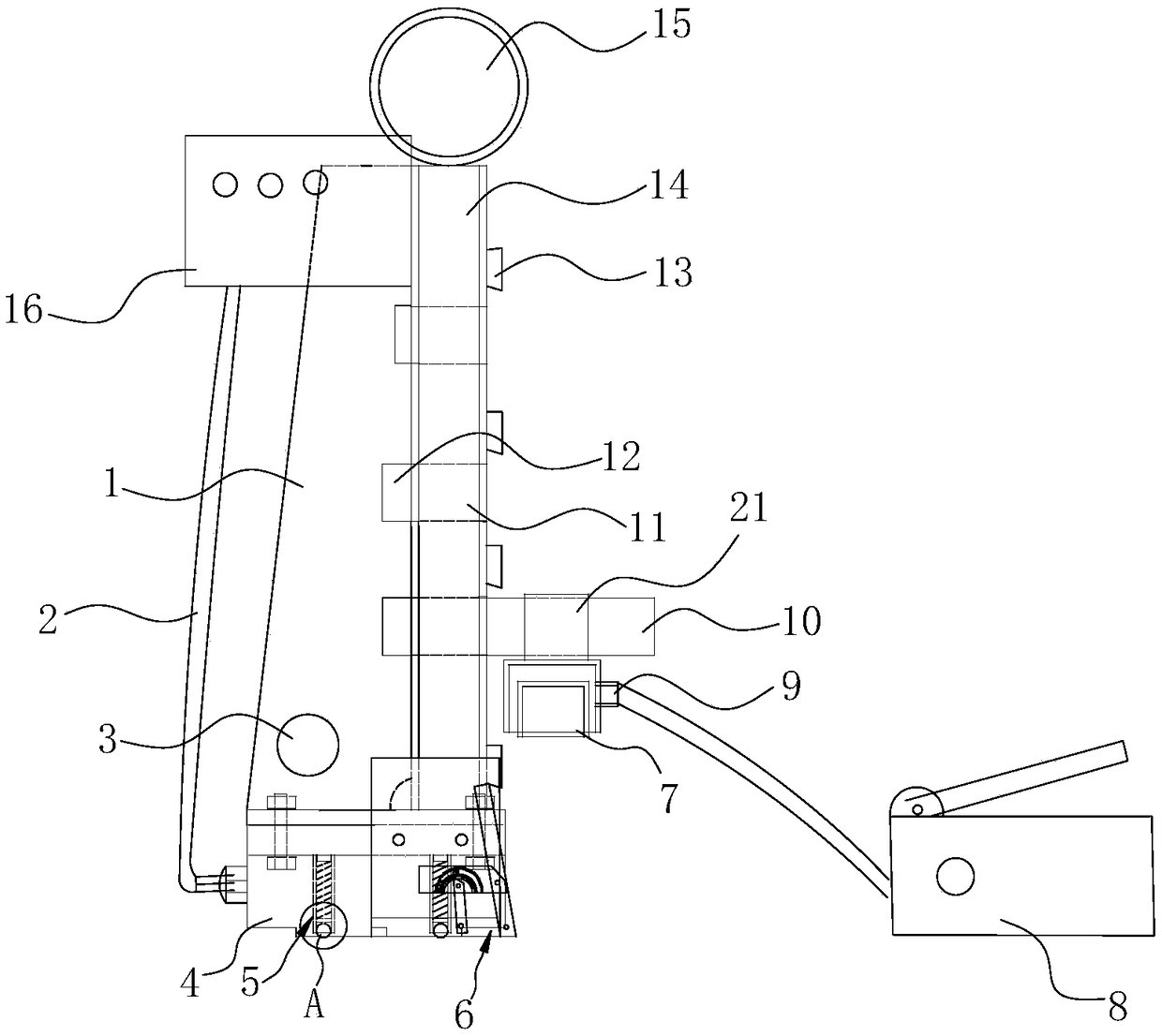

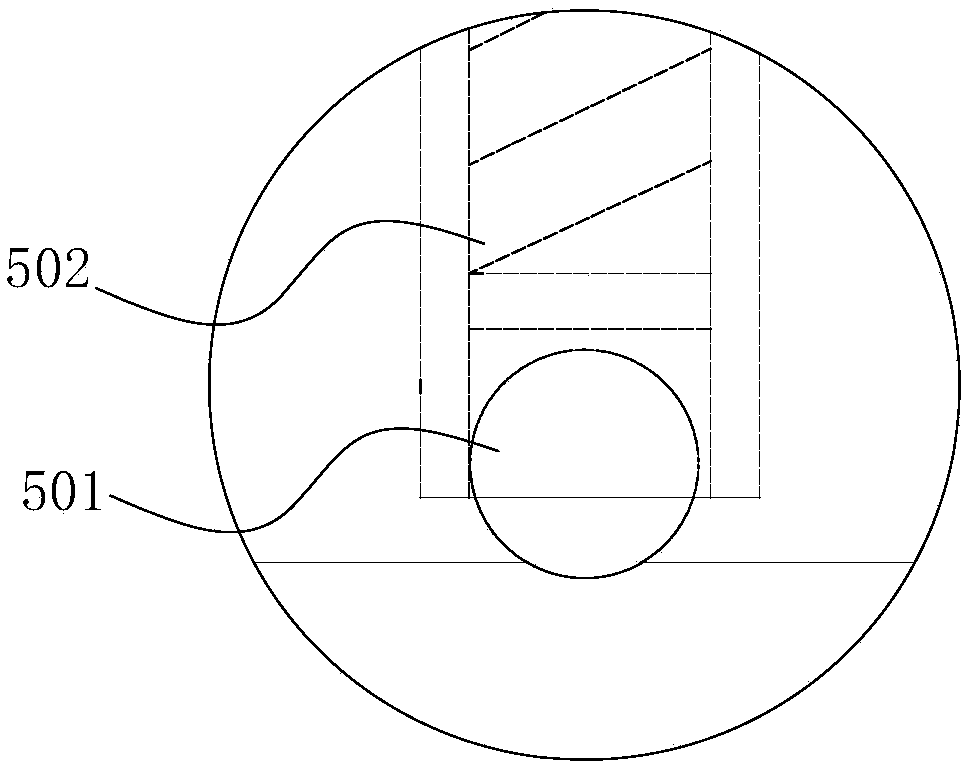

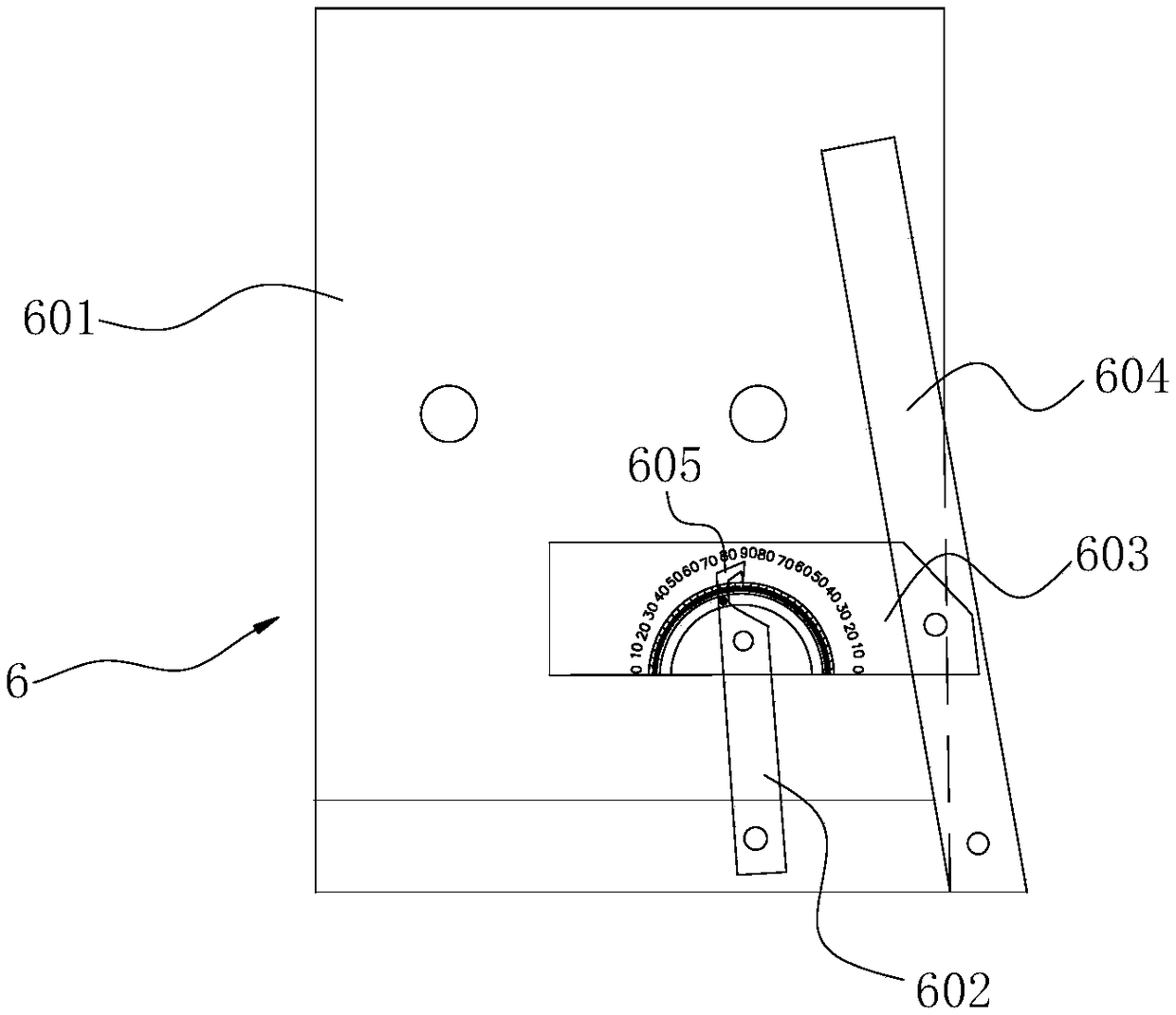

[0039] Such as Figure 1-7 As shown, in this embodiment, the multi-functional installation tool without horse feet according to the present invention includes a support plate 1, an adsorption device 4 arranged on the support plate 1 for connecting with the motherboard 19, and used for Carry out the clamping device that the sub-board that is welded and connected with the motherboard 19 is fixed on the motherboard 19 along the vertical direction; The jigsaw pulling device that is used to pull the multi-function non-code foot installation tool along the horizontal direction; The device is a manual oil pump, including an oil top 7 and an oil pump controller 8 for controlling the action of the oil top 7. An adjustment rod 10 is arranged on the support plate 1, and the pressing device is movable through t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com