A three-phase brushless DC motor durability test bench

A brushed DC motor and test bench technology, which is applied in the direction of motor generator testing, components of electrical measuring instruments, measuring electricity, etc., can solve the problems of low efficiency of assembly methods and low efficiency of motor durability testing, and achieve the reduction of motor durability testing. Difficulty, improvement of durability test efficiency, and the effect of increasing motor load

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

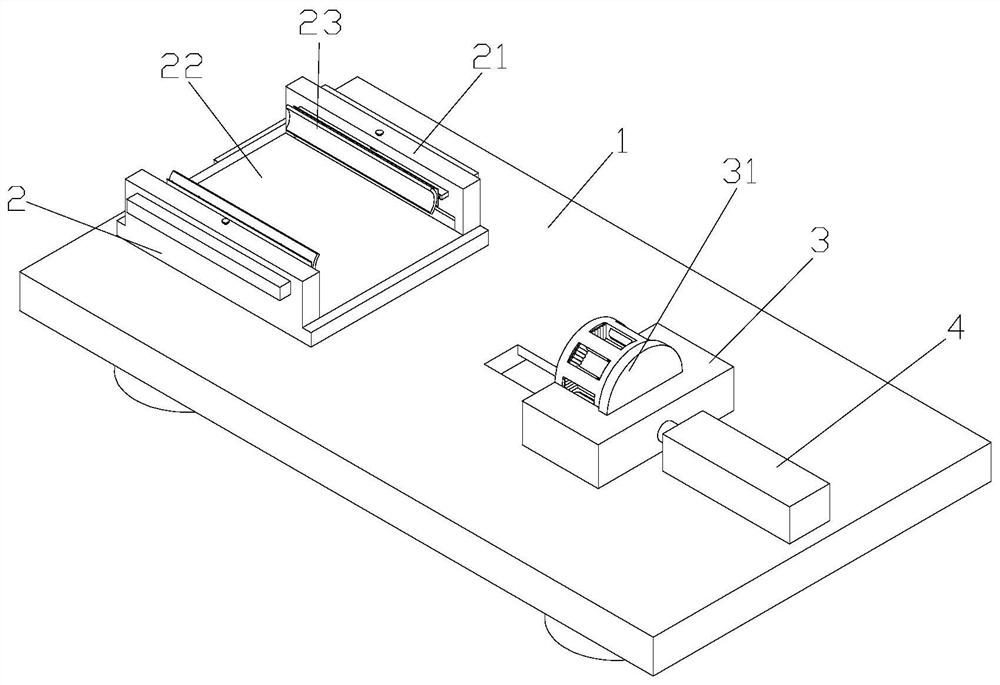

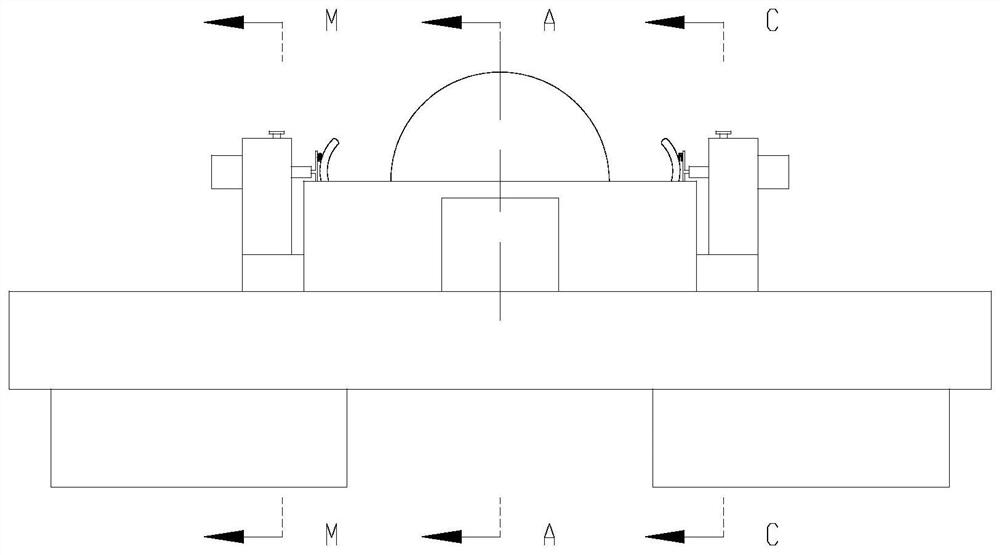

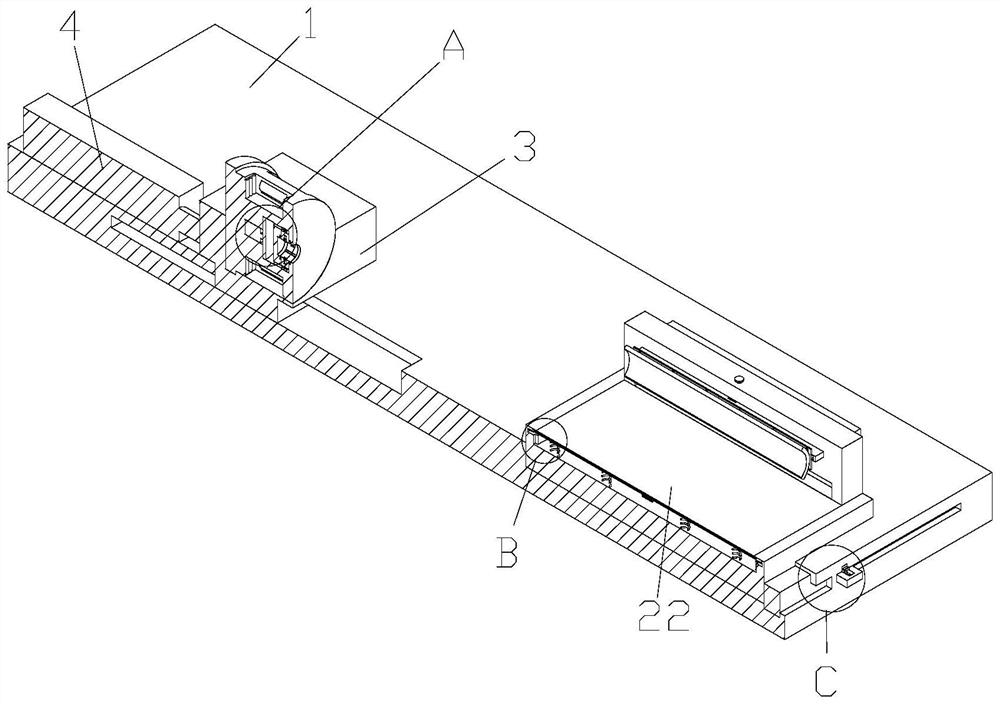

[0038] like Figure 1-22 As shown, a three-phase brushless DC motor durability test bench includes a base 1, a loading plate 2 arranged on the base 1 and a mounting block 3 arranged on one side of the loading plate 2, the base 1 is provided with a first chute and a second chute, the bottom of the loading plate 2 is provided with a first slider 220 matching the first chute, and the bottom of the mounting block 3 is provided with a The second slider matched with the second chute, the base 1 is provided with an electric push rod 4 matched with the installation block 3, the installation block 3 is provided with a first movable groove, and the first A counterweight plate 31 is provided in the movable groove, and a plurality of mounting grooves are provided on the side wall of the counterweight plate 31, and counterweight blocks are provided in the described mounting groove; connecting holes are provided on the counterweight plate 31, so that A connection assembly is provided in th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com