Optical element adjusting frame

A technology of optical components and adjustment mounts, applied in the field of optics, can solve problems such as difficulties, Z-axis translation cannot be adjusted independently, optical path crosstalk, etc., and achieve the effect of compact and practical structure, improved convenience and stability, and avoiding optical crosstalk

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

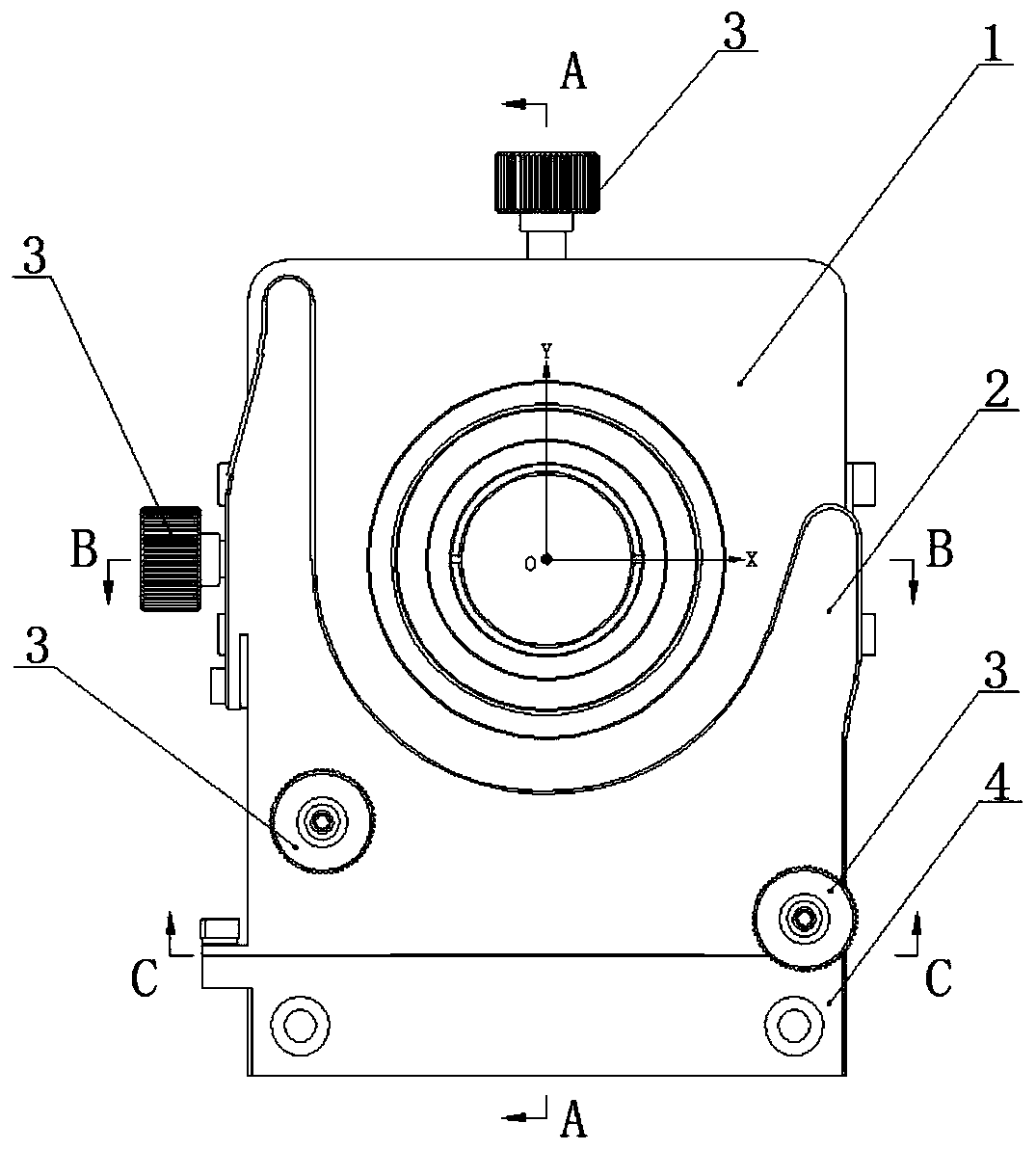

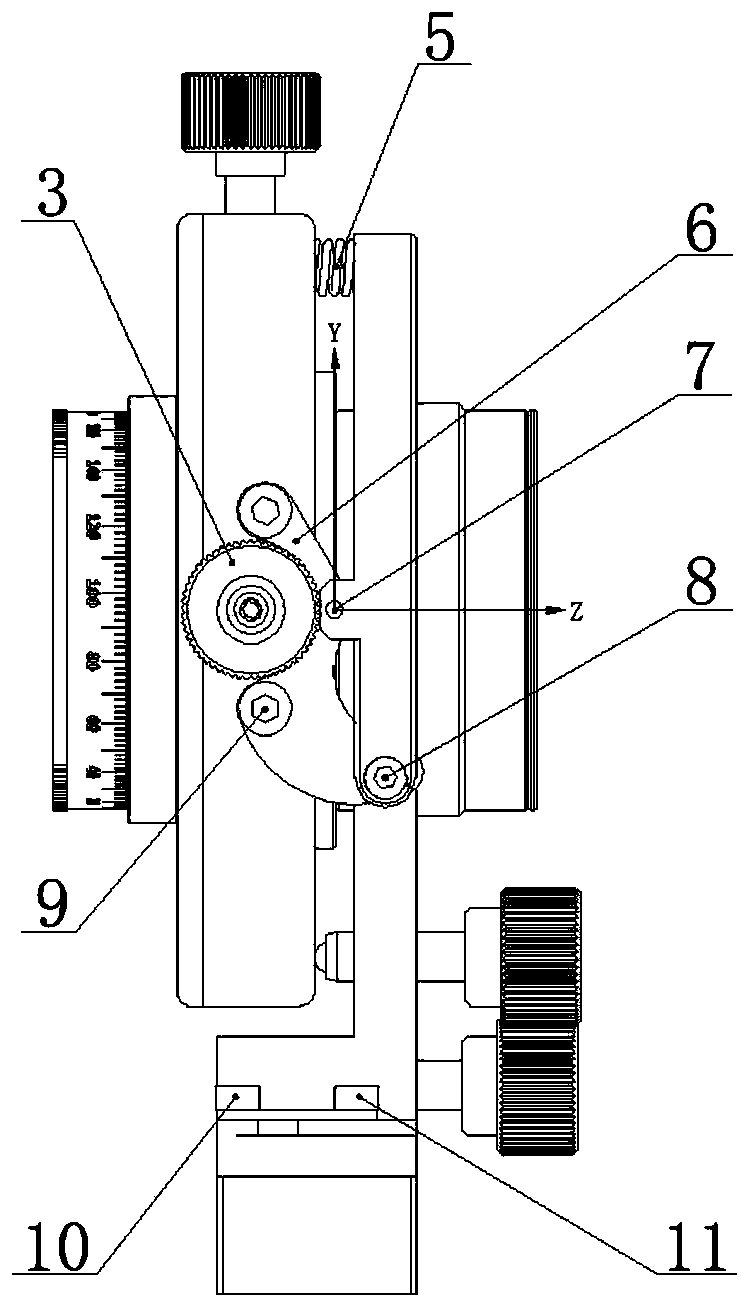

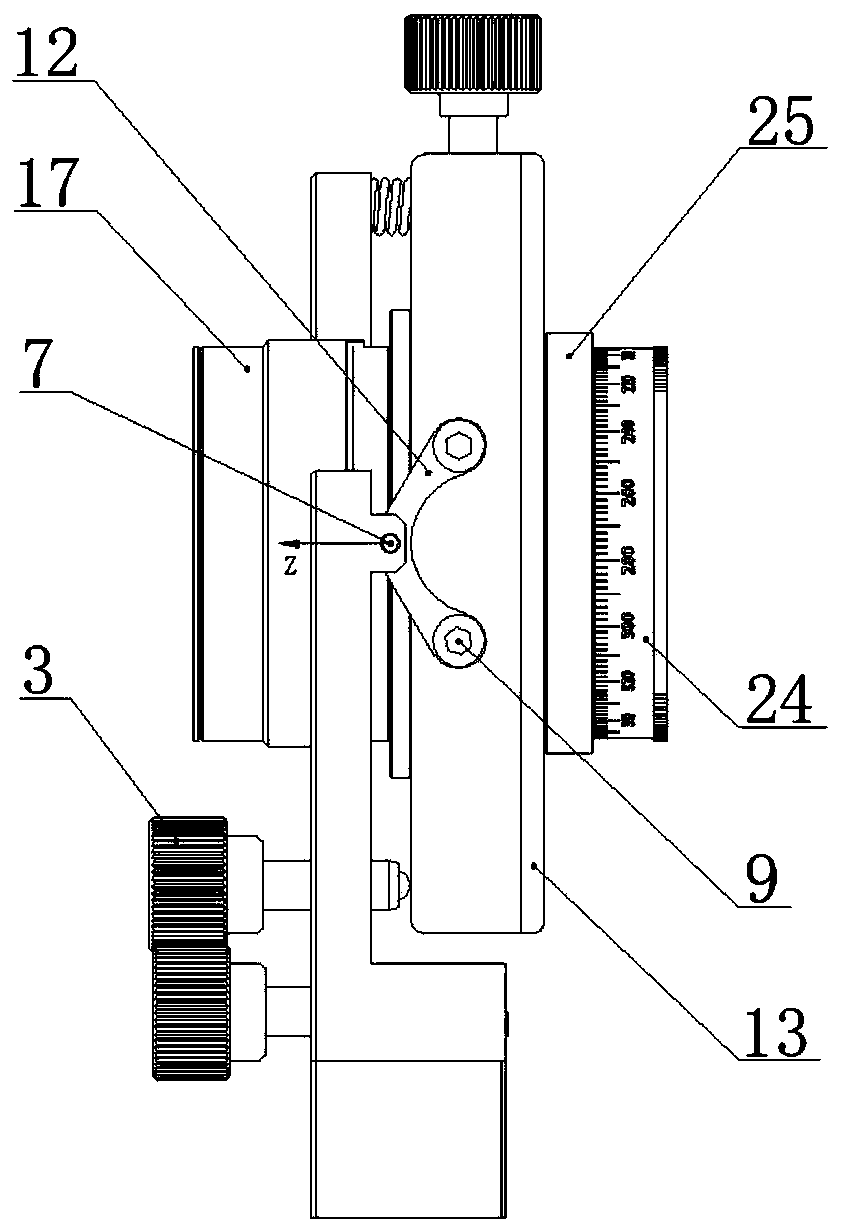

[0032] This embodiment discloses an optical element adjustment frame.

[0033] Such as Figure 1 to Figure 7 As shown, the adjustment frame of this embodiment includes: a support frame 1, a rotating frame 2, a hand screw 3, a base 4, a compression spring 5, a right pitch bracket 6, a cylindrical pin 7, a locking screw 8, a fixing screw 9, a locking screw Block 10, locking screw 11, left pitch bracket 12, rear cover 13, optical element mounting ring 14, snap ring 15, cover 16, front knob 17, limit ring 18, first jacking screw 19, connecting ring 20 , limit block 21, translation ring 22, second top wire 23, rear knob 24, locking ring 25, pagoda spring 26, rotating pin 27, compression spring 28, limit screw 29, limit pin 30.

[0034] In this embodiment, the optical element is installed in the optical element mounting ring 14, and is fixed by pressing the snap ring 15. The mounting ring has a positioning step. When the mounting ring is translated to the final position, the positi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com