Three-dimensional laminated iron core yoke column equal-flux-density structure and method

A technology of stacking iron cores and iron yokes, which is applied in the field of magnetic density structures, can solve problems such as excessive closing current and transformer damage, and achieve the effects of reducing magnetic flux leakage, stable product performance, and increasing axial compression force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The present invention will be further elaborated below in conjunction with the accompanying drawings of the description.

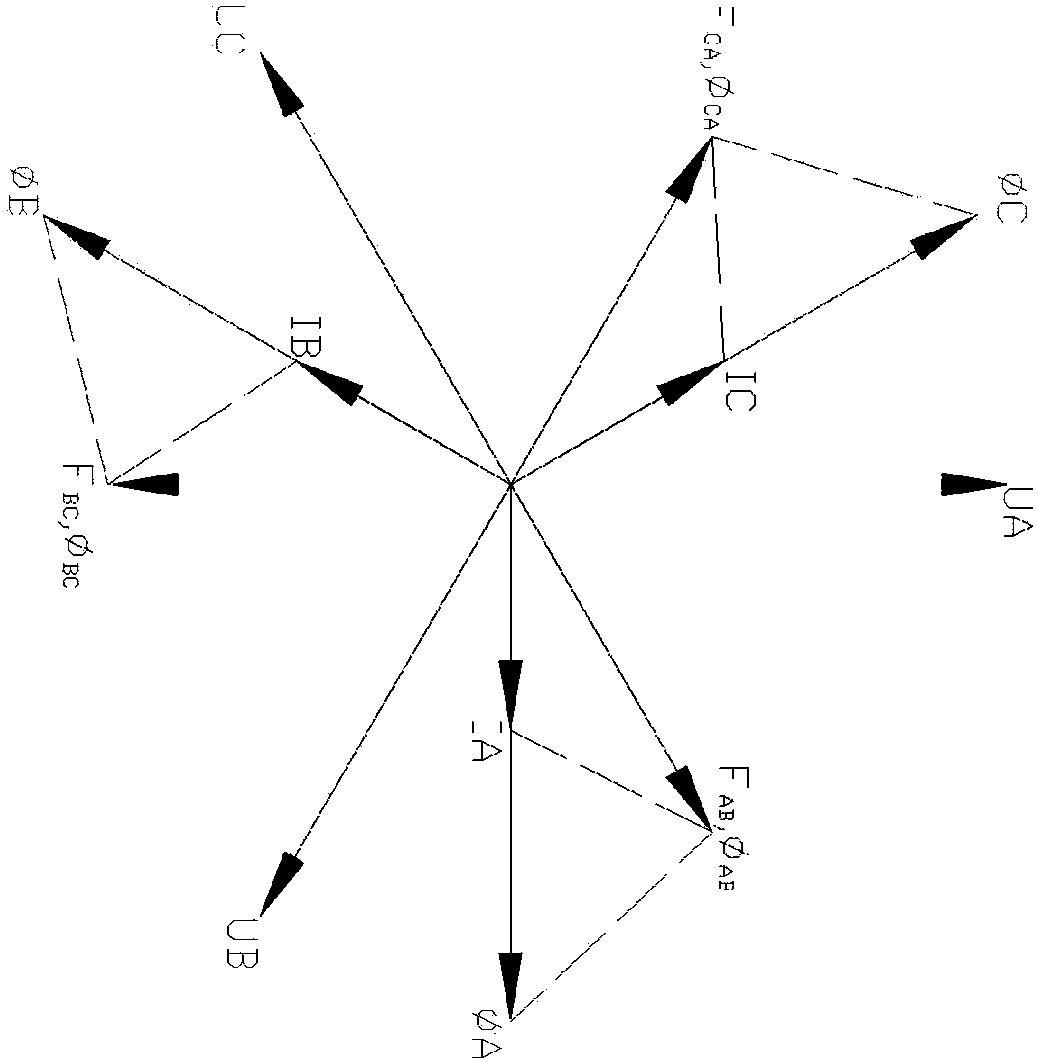

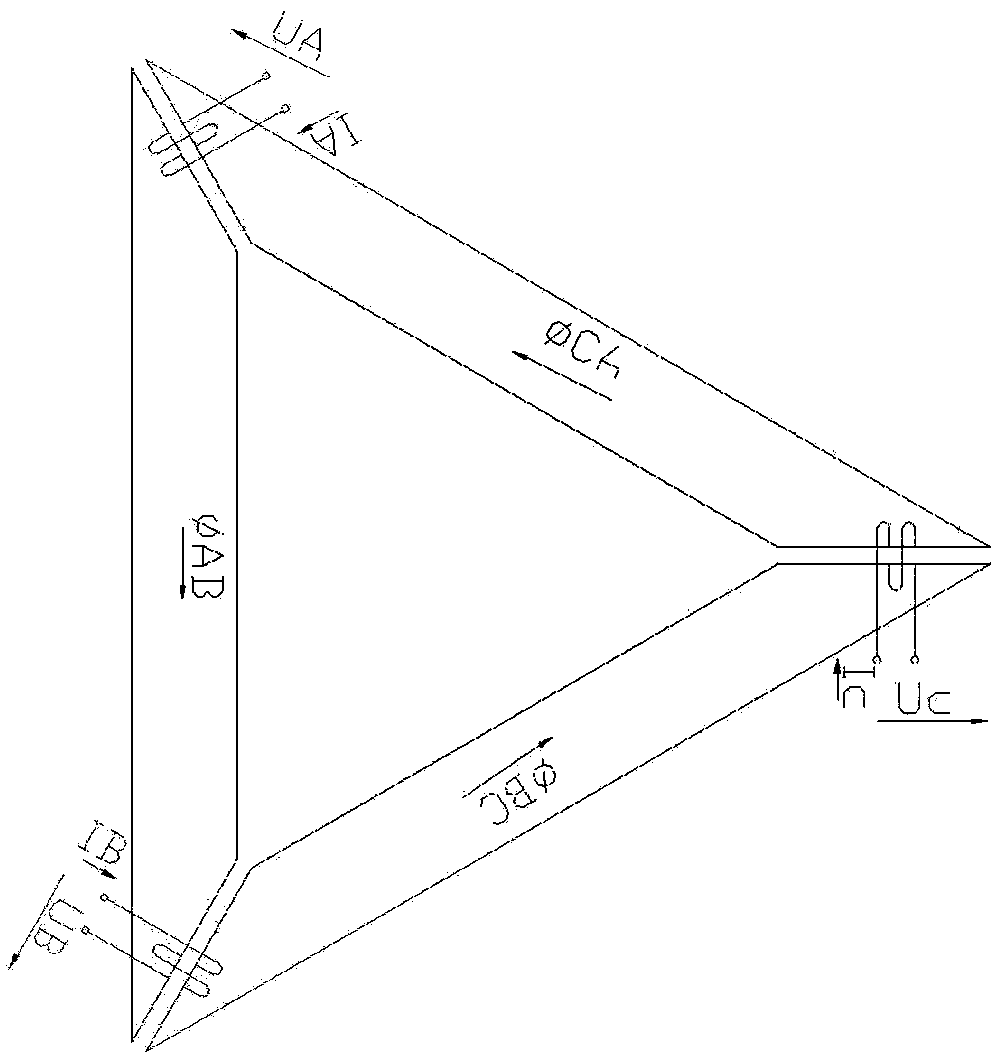

[0040] The present invention is a three-dimensional stacked iron core structure with equal magnetic density of yoke columns, including three-frame iron cores, upper iron yokes, lower iron yokes and core columns. The sheet type of the upper and lower iron yokes 5 and 6 increases the number of iron core laminations in the iron core iron yoke; increases the cross-sectional area of the iron core lower iron yoke 6 to make it larger than the cross-sectional area of the core column. In this way, the magnetic density of the iron yoke can be reduced, and the magnetic density performance of the three-dimensional stacked iron yoke column can be satisfied.

[0041] The widening of iron yoke is: adjust the width of iron yoke at all levels, and the adjustment ratio is 1.153.

[0042] Such as Figure 5 As shown in the figure, the joints at both ends of the i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com